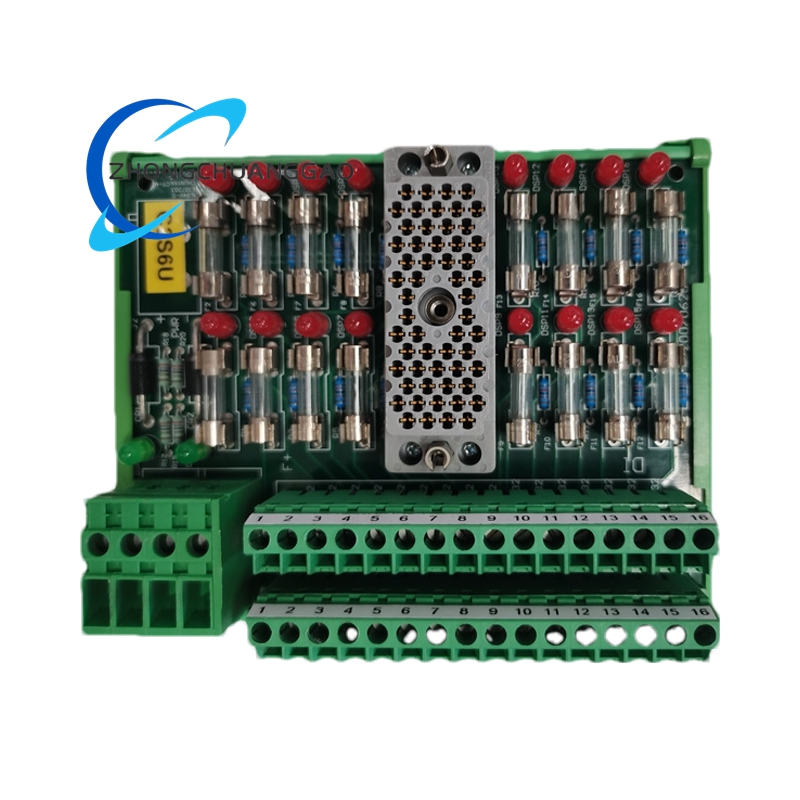

TRICONEX 3000540-380 Digital Input Terminal Module

Technical Specifications

- Voltage Rating: 24VDC

- Input Channels: Multiple digital input channels (specific quantity depends on configuration)

- Signal Type: Digital (on/off)

- Redundancy: Triple Modular Redundant (TMR) design with three independent signal paths

- Safety Standards: Compliant with IEC 61508 SIL 3 and other international safety certifications

- Operating Temperature: -40°C to 70°C

- Enclosure: IP20 (protection against solid objects >12.5mm)

- Mounting: DIN rail or panel mounting

- Weight: Approximately 0.5 kg

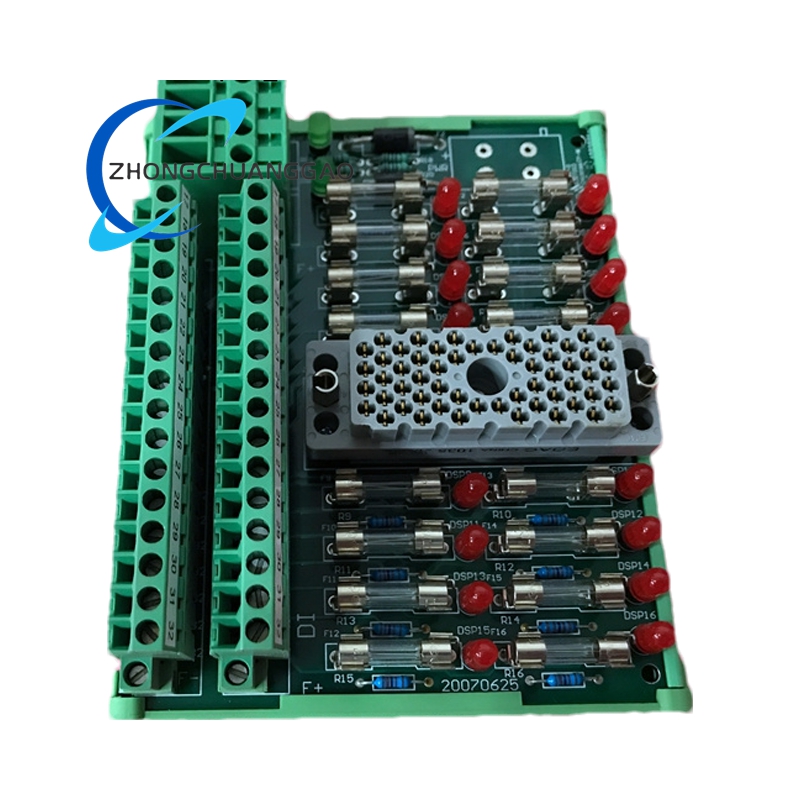

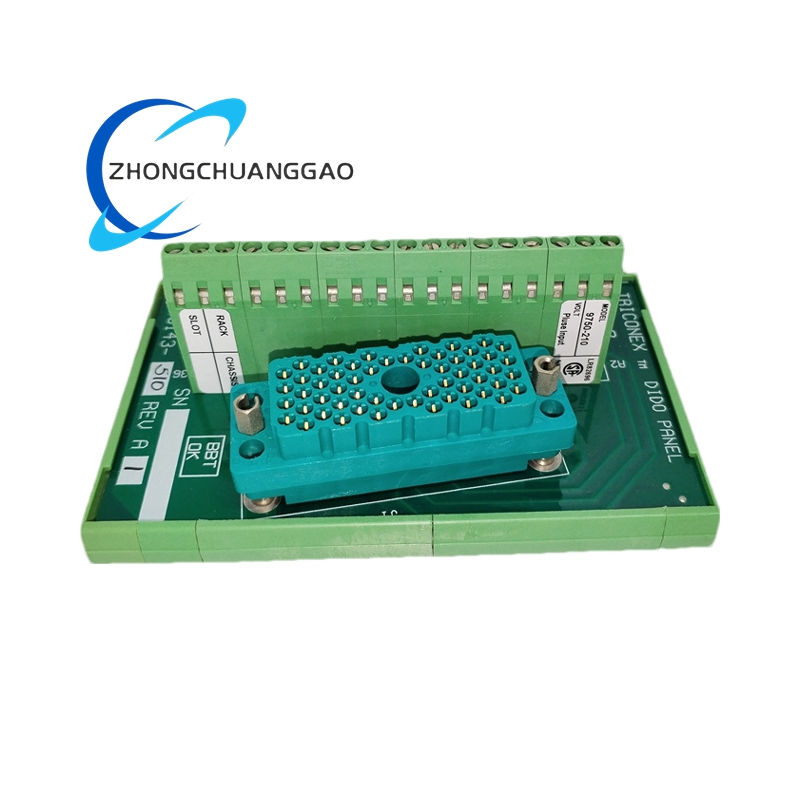

TRICONEX 3000656-210-REVA Fault-Safe I/O Module

Technical Specifications

- Channels: 16 digital input/output channels

- Signal Type: Digital input/output

- Voltage Range: 24 VDC

- Current Range: 2 A

- Response Time: ≤2 ms

- Protection Class: IP67

- Operating Temperature Range: -40°C to 70°C

- Dimensions: 144 x 64 x 32 mm

- Weight: 0.5 kg

- Mounting Options: DIN rail or panel mounting

- Interface Type: Tribus

- Safety Standards: Compliant with IEC 61508 and SIL 3

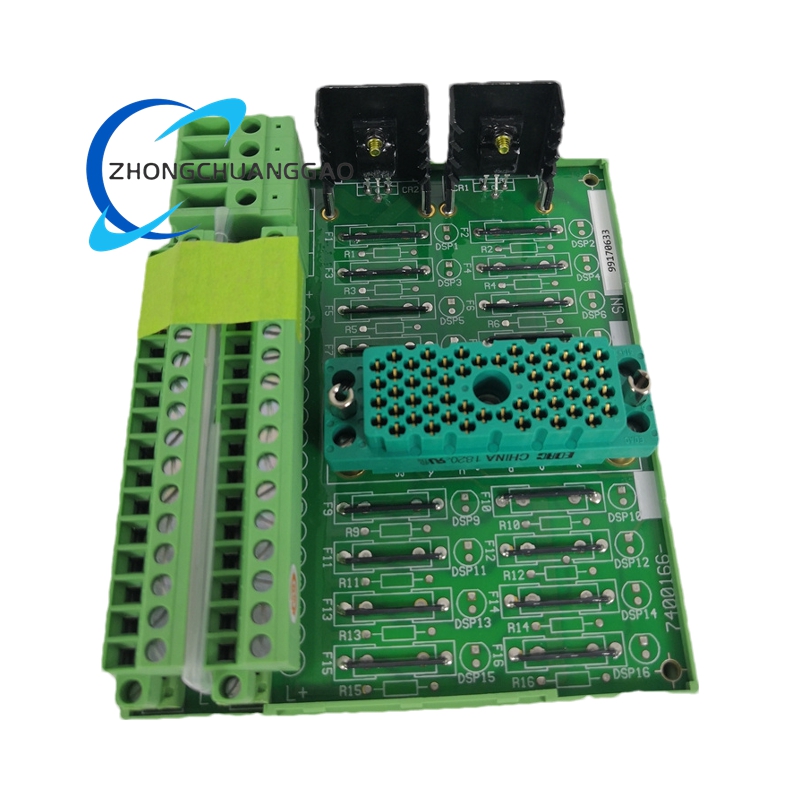

TRICONEX 3000520-390 Input/Output Communication Base Module

Technical Specifications

- Brand: Triconex (Invensys, now part of Schneider Electric)

- Origin: Manufactured in China (e.g., Hebei Qinhuangdao)

- Weight: Approximately 0.2 kg

- Dimensions: 23 cm in length

- Color: Green

- Certifications: Compliant with international safety standards such as IEC 61508 SIL 3

- Operating Environment:

- Temperature: Normal operating conditions

- Humidity: Non-condensing

- System Compatibility: Supports PLC (Programmable Logic Controller) systems

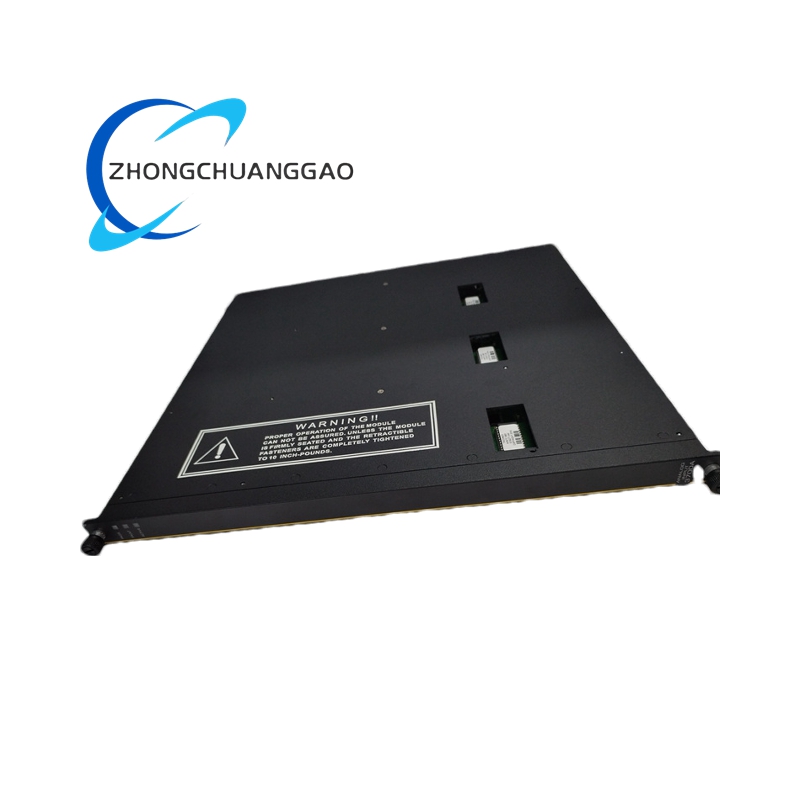

TRICONEX 3000510-380

Technical Specifications

- Brand: Triconex (Invensys, now part of Schneider Electric)

- Origin: United States

- Weight: Approximately 0.1 kg

- Certifications: Compliant with IEC 61508 SIL 3 and other international safety standards

- Support System: Compatible with Distributed Control Systems (DCS)

- Customization: Not customizable

- Condition: Brand new

- Stock Status: Available

TRICONEX 3000475-520

Technical Specifications

- Brand: Invensys (now part of Schneider Electric)

- Origin: France

- Model Number: 3000475-520

- Operating Temperature Range: -25°C to 85°C (operation); -60°C to 125°C (storage)

- Humidity Range: 5% to 95% RH (non-condensing)

- Dimensions: Approximately 234mm in length

- Weight: Between 2kg and 7kg

- Certifications: Compliant with IEC 61508 SIL 3 and other international safety standards

TRICONEX 3000470-510

Technical Specifications

- Brand: Invensys Triconex

- Origin: France

- Model Number: 3000470-510

- Work Voltage: 240V

- Output Frequency: Up to 100kHz

- Operating Temperature Range: -25°C to 85°C (operation); -60°C to 125°C (storage)

- Humidity Range: 5% to 95% RH (non-condensing)

- Dimensions: Approximately 234mm in length

- Weight: Between 2kg and 7kg

- Certifications: Compliant with IEC 61508 SIL 3 and other international safety standards

TRICONEX 3000110-360

Technical Specifications

- Brand: Invensys (now part of Schneider Electric)

- Origin: United States

- Physical Dimensions: Approximately 200mm × 150mm × 80mm

- Weight: Around 0.5 kg

- Power Supply: Supports redundant power inputs for enhanced reliability.

- Operating Temperature: -20°C to +70°C (industrial-grade reliability).

- Storage Temperature: -50°C to +85°C.

- Mounting: Rack-mounted design for easy integration into Triconex systems.

- Certifications: Complies with IEC 61508 SIL 3 and other international safety standards.

TRICONEX 2481 Backplane Module

Technical Specifications

- Model: TRICONEX 2481

- Brand: Invensys (now part of Schneider Electric)

- Origin: Switzerland

- Dimensions: Approximately 200mm × 150mm × 80mm

- Weight: Around 0.5 kg

- Power Supply: Supports redundant power inputs for enhanced reliability.

- Operating Temperature: -20°C to +70°C (industrial-grade reliability).

- Storage Temperature: -50°C to +85°C.

- Mounting: Rack-mounted design for easy integration into Triconex systems.

- Certifications: Complies with IEC 61508 SIL 3 and other international safety standards.

TRICONEX 2351 Analog Input Backplane Module

Technical Specifications

- Input Types: Supports multiple analog input signals, including current (4-20mA, 0-20mA), voltage (±10V to ±100V), thermocouples, and RTDs (e.g., Pt100).

- Resolution: 16-bit high-resolution measurement for accurate signal conversion.

- Accuracy: ±0.1% FSR (Full-Scale Range) to minimize measurement errors.

- Update Rate: Real-time data refresh for dynamic process monitoring.

- Power Supply: 24V DC input with stable voltage regulation.

- Operating Temperature: -20°C to +70°C (industrial-grade reliability).

- Storage Temperature: -50°C to +85°C for harsh environmental conditions.

- Dimensions: 200mm x 150mm x 80mm (compact design for space-efficient installations).

- Weight: Approximately 0.5 kg.

- Safety Certifications: Complies with IEC 61508 SIL3 and ISA-S84 standards for safety-critical applications.

TRICONEX MA2211-100 Digital Input Module

Technical Specifications

- Input Channels: Multiple digital input channels for connecting external digital signals.

- Electrical Isolation: Provides electrical isolation to prevent external interference and enhance system reliability.

- Communication Interface: Features communication interfaces (e.g., PCIe-based design) for seamless integration with PLCs, DCS, or other control systems.

- Redundancy: Supports TMR architecture, enabling continuous operation even if one channel fails.

- Measurement Capabilities: Can measure physical parameters like temperature, pressure, flow, humidity, and liquid levels with high precision.

- Compliance: Meets industrial standards such as IEC 61508 (SIL 3) for safety-critical applications.

TRICONEX 2000361-001 Digital Output Module part of Triconex Tricon system

Technical Specifications

- Brand: TRICONEX (a Schneider Electric brand)

- Model: 2000361-001

- Redundancy: Triple-modular redundant (TMR) design with three independent channels per output signal.

- Output Type: Digital outputs (specific voltage/current ratings depend on system configuration).

- Diagnostic Coverage: Full hardware and software diagnostics for each channel, including output feedback verification.

- Communication: Integrated into the Triconex Tricon system via TriBus for real-time data exchange between modules.

- Environmental: Designed for harsh industrial environments with high resistance to electromagnetic interference (EMI) and temperature extremes.

- Certifications: Complies with international safety standards such as IEC 61508 (SIL 3), TÜV, and other industry-specific approvals.

Triconex 9853-610 Analog Input Terminal Block

Technical Specifications

- Electrical Parameters

- It supports multiple analog input ranges, including 0 - 10V, -10V to 10V, 4 - 20mA, and 0 - 20mA, covering the signal requirements of most industrial field sensors.

- It has a measurement accuracy of ±0.1% and a resolution of 12 bits, and the signal update rate reaches 250ms, which can ensure the accuracy and real-time performance of data collection.

- It uses a 24VDC power supply, with a power consumption of only 5W, which will not add excessive power burden to the overall safety system.

- Physical Parameters

- Its overall dimensions are 110mm × 45mm × 22mm, and its weight is 150g. The compact and lightweight design allows it to be flexibly installed in control cabinets with limited space.

- It is equipped with screw-type terminals, which can provide firm wiring connections and avoid poor contact caused by vibration in industrial environments.