Triconex 4000093-320 Enhanced Communication Module

Technical Specifications:

- Origin: United States

- Manufacturer: Triconex (a subsidiary of Invensys Group)

- Type: Enhanced Communication Module

- Output Current Range: 4-20 mA (+6% overrange capability)

- Number of Output Channels: 8

- Current Loop Type: DC-coupled

- Redundancy Architecture: Triple Modular Redundant (TMR)

- Analog Output (AO) Resolution: 12-bit

- Output Accuracy: <0.25% of full-scale range (FSR) within the 4-20 mA range, from 0 to 60°C

- Transport Weight: Approximately 3 kilograms

- Environmental Conditions: Designed to withstand harsh industrial environments, including wide temperature ranges and resistance to vibration and shock

- Certifications: Meets international safety standards and certifications, ensuring compliance with regulatory requirements

Triconex 4000093-310 Communication Module

Technical Specifications:

- Compatibility: Specifically designed for Triconex SIS, ensuring optimal performance and integration.

- Communication Protocols: Supports various communication protocols to enable connectivity with different industrial networks and devices.

- Interface Options: Equipped with multiple interface options for flexible connection to other system components.

- Redundancy: May support redundant configurations to enhance system availability and fault tolerance.

- Environmental Conditions: Built to withstand harsh industrial environments, including wide temperature ranges and resistance to vibration and shock.

- Certifications: Meets international safety standards and certifications, ensuring compliance with regulatory requirements.

Triconex 3900064-003

Technical Specifications:

- Architecture: Triple Modular Redundant (TMR) design for enhanced fault tolerance and system availability.

- Safety Integrity Level (SIL): Certified for SIL 3 applications, indicating the highest level of safety integrity.

- Input/Output Channels: Supports multiple input and output channels, depending on the specific configuration and application requirements.

- Communication Protocols: Compatible with various communication protocols for seamless integration into existing industrial networks.

- Environmental Conditions: Designed to operate reliably in harsh industrial environments with wide temperature ranges and resistance to vibration and shock.

- Certifications: Meets international safety standards and certifications, ensuring compliance with regulatory requirements.

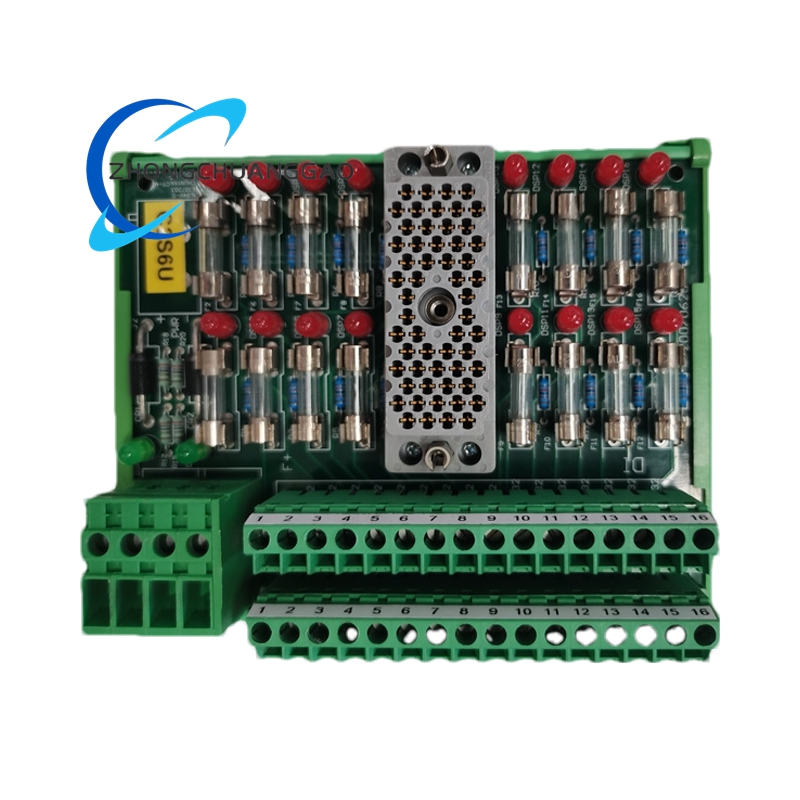

Triconex 3807 Bipolar Analog Output Module

Technical Specifications:

- Brand: Triconex

- Model Number: 3807

- Type: Bipolar Analog Output Module

- Output Channels: Multiple channels for bipolar analog output signals

- Output Range: Capable of generating both positive and negative voltage outputs, suitable for a wide range of control applications

- Isolation: Provides isolation between channels and between the module and the system to enhance safety and reduce interference

- Accuracy: High-precision output to ensure accurate control of actuators and other devices

- Compatibility: Designed to work seamlessly with Triconex Tricon and Trident SIS systems

- Environmental Conditions: Operates reliably in harsh industrial environments with wide temperature ranges and resistance to vibration and shock

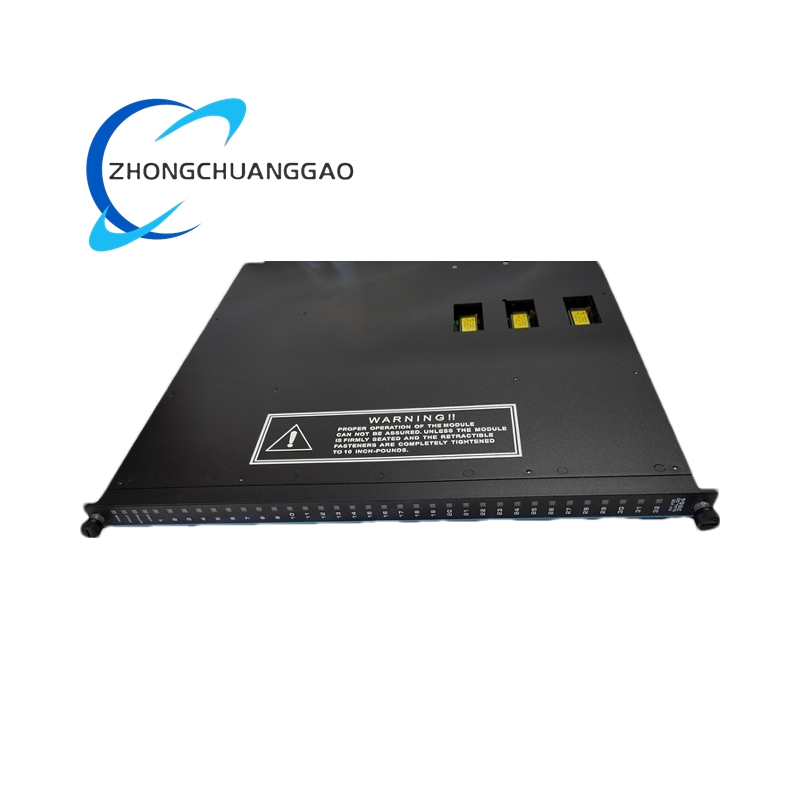

Triconex 3806E

Technical Specifications:

- Output Channels: 8 independent channels (6 channels support 4-20 mA output, 2 channels support 20-320 mA output).

- Resolution: 12-bit, ensuring high-precision output.

- Output Accuracy: Less than 0.25% of full-scale range (FSR) from 0°C to 60°C, guaranteeing accurate signal conversion.

- Output Range: 4-20 mA (with +6% overrange capability) and 20-320 mA for specific applications.

- Isolation: 2500 VAC reinforced isolation between channels, preventing interference and enhancing safety.

- Diagnostic Functions: Includes current loopback self-test and load open-circuit detection for comprehensive fault monitoring.

- Power Supply: Supports redundant loop power for increased reliability.

- Hot-Swap Capability: Allows for module replacement without system shutdown, minimizing downtime.

- Weight: Approximately 4 kilograms.

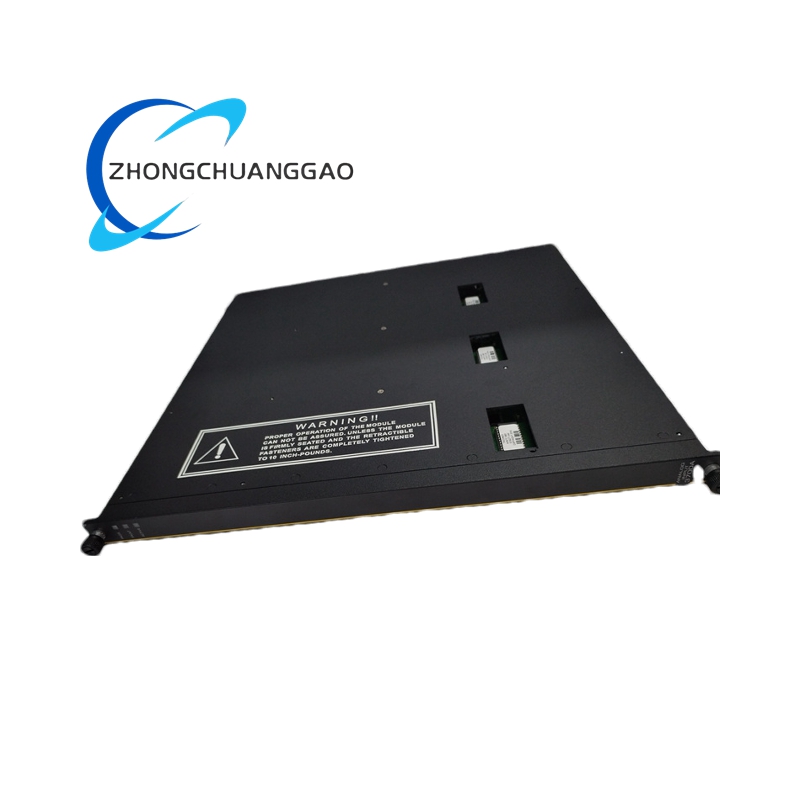

Triconex 3805E

Technical Specifications:

- Input/Output Channels: Multiple digital input and output channels, allowing for simultaneous monitoring of multiple digital signals or control of multiple devices.

- High-Density Configuration: Designed to save space and reduce the number of devices required in a system.

- High-Speed Input: Supports high-speed digital input for monitoring rapidly changing digital signals.

- High-Precision Input: Provides high-precision digital inputs to ensure accurate data collection.

- Digital Filtering: Incorporates digital filtering functions to reduce the impact of noise and interference on digital signals.

- Logic Functions: Capable of performing logical operations on digital input signals, such as AND, OR, NOT, etc.

- Trigger Function: Supports trigger functions to enable digital output based on specific conditions.

Triconex AIH 3723X

Technical Specifications:

- Communication Interfaces: RS-485, Ethernet

- Data Transmission Rate: Up to 10 Mbps

- Supported Protocols: Modbus, Profibus, HART, and other industrial communication protocols

- Isolation: Provides isolation between input/output, power supplies, and racks to enhance safety and prevent interference

- Protection Rating: IP67, ensuring resistance to dust and water ingress

- Dimensions: 130 mm x 110 mm x 22 mm

- Weight: 0.5 kg

- Material: Aluminum alloy

- Operating Temperature Range: -40°C to +70°C

- Storage Temperature Range: -55°C to +85°C

Triconex 3721C

Technical Specifications:

- Input Type: Supports multiple input types, including voltage, current, thermocouple, and RTD (Resistance Temperature Detector).

- Voltage Range: 0 to 5 VDC or -5 to +5 VDC, with an additional ±6% tolerance.

- Input Points: 32 differential, DC-coupled channels.

- Input Update Rate: 10 milliseconds for rapid data acquisition.

- Resolution: 12-bit or 14-bit programmable for high-precision measurements.

- Accuracy: Less than 0.15% of full-scale range (FSR) from 0°C to 60°C, ensuring precise signal conversion.

- Common-Mode Rejection: -85 dB (DC–100 Hz) to minimize interference from external sources.

- Input Overrange Protection: Continuous protection up to 150 VDC/115 VAC to safeguard against voltage surges.

- Weight: 1.36 kilograms for easy installation and handling.

Triconex 3721

Technical Specifications:

- Input Type: 32 differential, DC-coupled channels for analog input.

- Voltage Range: 0-5 VDC or -5 to +5 VDC.

- Input Update Rate: 10 milliseconds for rapid data acquisition.

- Resolution: 12-bit or 14-bit programmable for high-precision measurements.

- Accuracy: Less than 0.15% of full-scale range (FSR) from 0°C to 60°C, ensuring precise signal conversion.

- Isolation: Each channel is electrically isolated with a typical leg-to-leg isolation resistance of 420 kΩ, preventing interference and enhancing safety.

- Input Overrange Protection: Continuous protection up to 150 VDC/115 VAC to safeguard against voltage surges.

- Diagnostic Indicators: PASS, FAULT, ACTIVE, and FIELD indicators for comprehensive system monitoring and troubleshooting.

- Color Code: Yellow for easy identification.

- Environmental Conditions: Designed to operate in harsh industrial environments, withstanding extreme temperatures, shock, and vibration.

Triconex 3721

Technical Specifications:

- Input Type:

- Analog Input: Supports 32 differential, DC-coupled channels for monitoring various types of analog signals, such as voltage or current.

- Digital Input: Provides 16 channels for monitoring digital signals (specific configurations may vary based on model and application).

- Voltage Range: 0-5VDC or -5 to +5VDC (differential), with additional support for other ranges depending on the configuration.

- Input Update Rate: 10 milliseconds for rapid data acquisition.

- Resolution: 12-bit or 14-bit programmable for high-precision measurements.

- Accuracy: Less than 0.15% of full-scale range (FSR) from 0°C to 60°C, ensuring precise signal conversion.

Triconex 3720

Technical Specifications:

- Voltage Range: Supports multiple voltage ranges, including 0-5VDC, ±5VDC, and 0-10VDC (selectable via software).

- Input Points: 64 single-ended inputs.

- Input Update Rate: 10 milliseconds for rapid data acquisition.

- Resolution: 12-bit or 14-bit programmable for high-precision measurements.

- Accuracy: Less than 0.15% of full-scale range (FSR) from 0°C to 60°C, ensuring precise signal conversion.

- Isolation: Each input channel is electrically isolated with a typical leg-to-leg isolation resistance of 420 kΩ, preventing interference and enhancing safety.

Triconex 3708E

Technical Specifications:

- Input Type: Thermocouple analog input

- Number of Channels: Multiple independent channels (specific configuration may vary based on model)

- Voltage Range: Supports standard thermocouple voltage ranges, typically 0-5Vdc or other ranges depending on the thermocouple type

- Accuracy: High precision with minimal error margins, ensuring accurate temperature measurement

- Isolation: Each channel is electrically isolated to prevent interference and enhance safety

- Environmental Conditions: Designed to operate in harsh industrial environments with appropriate temperature and humidity ranges

- Mechanical Design: Compact and rugged for easy installation in standard Triconex racks

- Certifications: Meets international safety standards, including IEC 61508 SIL 3 certification for safety integrity level