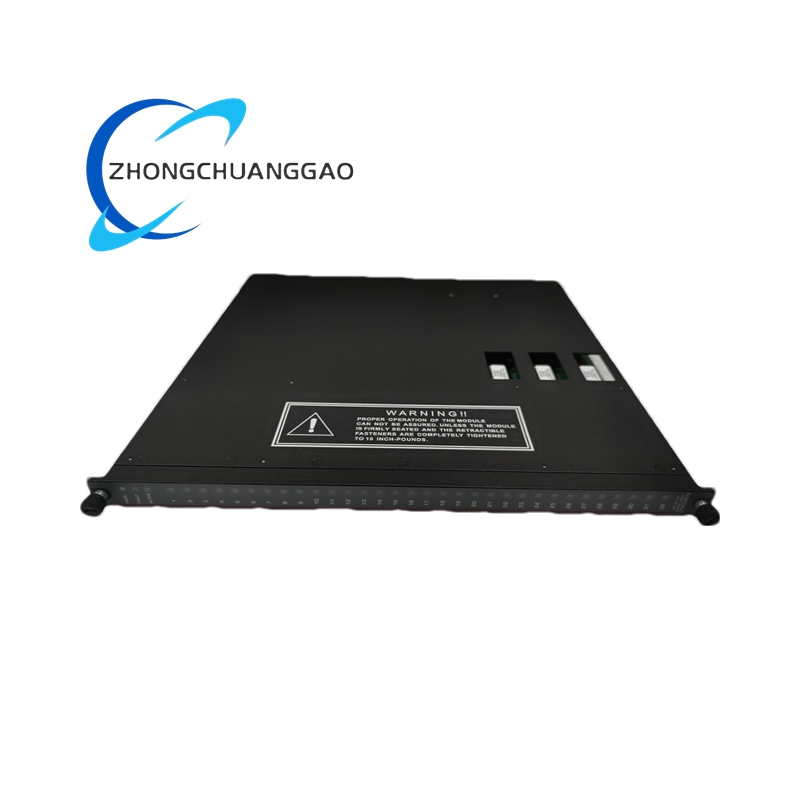

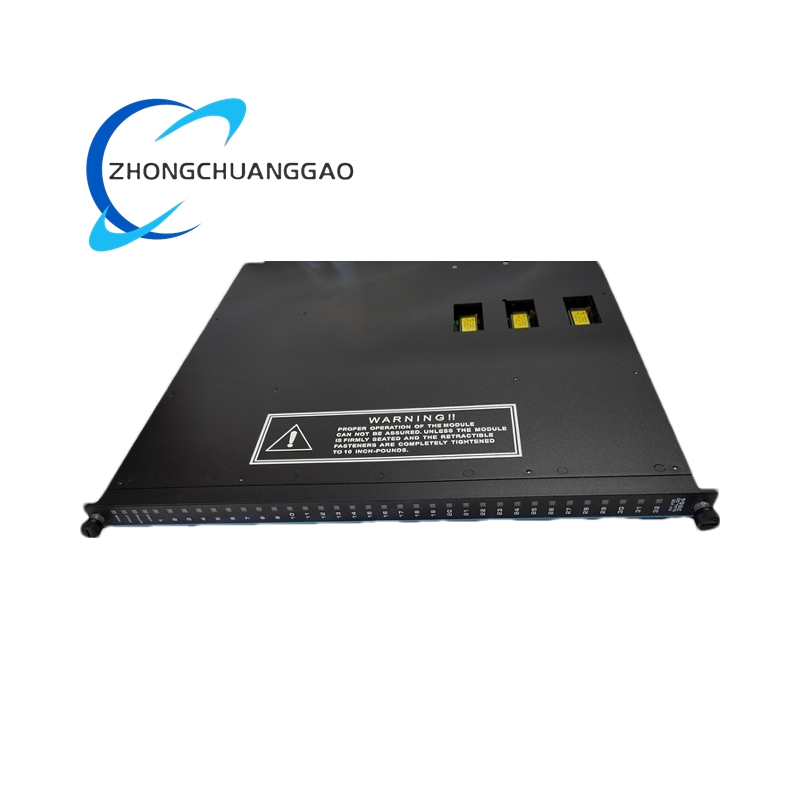

TRICONEX 3564 Digital Input Module

Technical Specifications

- Input Channels: Multiple isolated digital inputs (specific configurations vary by model, e.g., 32 or 64 channels).

- Input Voltage: Supports 115 VAC/DC or 24 VDC (model-dependent).

- Switching Level: Clear on/off thresholds (e.g., >86 VAC/DC for "on," <28 VAC/DC for "off").

- Response Time: Sub-millisecond for signal detection.

- Isolation: Each channel is electrically isolated from the system bus.

- Redundancy: TMR design with three independent channels per input.

- Certifications: SIL 3 (IEC 61508), TÜV Rheinland-certified.

- Operating Temperature: -40°C to +70°C (-40°F to 158°F).

- Mounting: DIN rail or panel-mounted.

TRICONEX 3501E Digital Input Module

Technical Specifications

- Input Channels: 32 isolated, non-shared digital inputs

- Input Voltage: 115 VAC/DC (90–155 VAC/DC range)

- Switching Level:

- On: >86 VAC/DC

- Off: <28 VAC/DC

- Frequency Range: DC or 47–63 Hz

- Response Time: Sub-millisecond for signal detection

- Hysteresis: Typical 32 VAC/DC

- Isolation: Each channel is electrically isolated from the system bus

- Redundancy: TMR design with three independent channels per input

- Certifications: SIL 3 (IEC 61508), TÜV Rheinland-certified

- Operating Temperature: -40°C to +70°C (-40°F to 158°F)

- Weight: Approximately 3 kg

- Mounting: DIN rail or panel-mounted

TRICONEX 3501E Digital Input Module

Technical Specifications

- Input Channels: 32 isolated, non-shared digital inputs

- Input Voltage: 115 VAC/DC (90–155 VAC/DC range)

- Switching Level:

- On: >86 VAC/DC

- Off: <28 VAC/DC

- Frequency Range: DC or 47–63 Hz

- Hysteresis: Typical 32 VAC/DC

- Response Time: Sub-millisecond for signal detection

- Isolation: Each channel is electrically isolated from the system bus

- Redundancy: TMR design with three independent channels per input

- Certifications: SIL 3 (IEC 61508), TÜV Rheinland-certified

- Operating Temperature: -40°C to +70°C (-40°F to 158°F)

- Weight: Approximately 3 kg

- Mounting: DIN rail or panel-mounted

TRICONEX 3451 Remote Terminal Unit/Relay Output Module

Technical Specifications

- Output Channels: 32 independent relay output channels

- Relay Type: Form A (SPST-NO) dry contact outputs

- Voltage Rating:

- Maximum: 30 VDC / 250 VAC

- Recommended: 24 VDC (common industrial standard)

- Current Rating: 2 A (resistive load per channel)

- Channel Isolation: Each channel is electrically isolated from the system bus

- Response Time: ≤10 ms

- Redundancy: TMR architecture with three independent channels per output

- Fault Tolerance: Single-channel failures do not disrupt operation; hot-swapping supported

- Communication: Compatible with Ethernet, RS-232, RS-485, and Modbus protocols

- Certifications: SIL 3 (IEC 61508), TÜV Rheinland-certified

- Operating Temperature: -20°C to +60°C

- Mounting: Plug-in module with dedicated base for secure installation

TRICONEX 3415

Technical Specifications

- Redundancy: TMR design with three independent channels for fault tolerance.

- Safety Integrity Level (SIL): SIL 3 certified, suitable for high-risk applications.

- I/O Capacity: Supports up to 70 I/O points (varies by module type).

- Processor: 32-bit CPU per channel, 50 MHz clock speed.

- Memory: 16 MB RAM per channel for complex logic execution.

- Communication: Ethernet, RS-232, RS-485, and Modbus protocols for integration with DCS or HMI systems.

- Operating Temperature: -20°C to +60°C (industrial-grade reliability).

- Power Supply: Dual redundant power inputs for uninterrupted operation.

- Certifications: TÜV Rheinland-certified, compliant with IEC 61508, ISA S84.01, and NFPA 72.

TRICONEX 3311 Digital Input Module

Technical Specifications

- Input Channels: 16 independent digital input channels

- Input Voltage Range: 18–32 VDC (typical 24 VDC)

- Input Current: ≤6 mA per channel

- Input Types: Dry contact or wet contact signals

- Channel Isolation: Each input channel is isolated from the system bus

- Redundancy Design: TMR (Triple Modular Redundant) input paths per channel

- Response Time: ≤5 ms (including filtering)

- Diagnostic Functions: Line monitoring, open-circuit detection, short-circuit detection

- Operating Temperature: -20°C to +60°C

- Storage Temperature: -40°C to +85°C

- Humidity Range: 5%–95% RH (non-condensing)

- Weight: Approximately 1.2 kg

- Mounting: Mechanically locked to prevent misinstallation

- Certifications: SIL 3 (IEC 61508), TÜV Rheinland-certified

TRICONEX DI3301 Digital Input Module

Technical Specifications

- Input Channels: 32 independent digital input channels

- Input Voltage Range: 18–32 VDC (typical 24 VDC)

- Input Current: ≤6 mA per channel

- Input Types: Dry contact or wet contact signals

- Channel Isolation: Each input channel is isolated from the system bus

- Redundancy Design: TMR (Triple Modular Redundant) input paths per channel

- Response Time: ≤5 ms (including filtering)

- Diagnostic Functions: Line monitoring, open-circuit detection, short-circuit detection

- Operating Temperature: -20°C to +60°C

- Storage Temperature: -40°C to +85°C

- Humidity Range: 5%–95% RH (non-condensing)

- Weight: 1.42 kg

- Mounting: Mechanically locked to prevent misinstallation

- Certifications: SIL 3 (IEC 61508), TÜV Rheinland-certified

TRICONEX CIM3211S2 Safety Interface Module

Technical Specifications

- Processors: Multiple 333 MHz CPUs for parallel processing.

- Memory: 64 MB RAM and 256 MB Flash for complex logic operations and data storage.

- Digital I/O: 32 channels, configurable as inputs or outputs to adapt to diverse field signal requirements.

- Analog I/O: 16 channels supporting high/low-state digital outputs and compatibility with various sensor signals.

- Communication Protocols: RS-232, RS-485, Ethernet for seamless integration with third-party devices (e.g., PLCs, DCS).

- Fieldbus Support: PROFIBUS DP, Modbus RTU, DeviceNet for simplified system architecture.

- Redundancy: Dual-channel redundant structure with automatic main/backup channel switching to ensure uninterrupted operation during single-point failures.

TRICONEX 3006MP Main Processor Module

Technical Specifications

- Model: 3006MP

- Manufacturer: Triconex (Schneider Electric)

- Architecture: Triple Modular Redundant (TMR)

- Voltage: +24V DC (via backplane)

- Power Consumption: <15W (typical)

- Operating Temperature: 0°C to +60°C

- Storage Temperature: -40°C to +85°C

- Protection Class: IP20

- Mounting: Standard 19-inch rack installation (Triconex chassis)

- Communication Interface: TriBus (high-speed dedicated bus for A/B/C chassis interconnection)

- Memory: Enhanced 2MB (or 1MB in earlier versions) for program and data storage

- Certifications: SIL 3 (IEC 61508/61511), TÜV Rheinland-certified

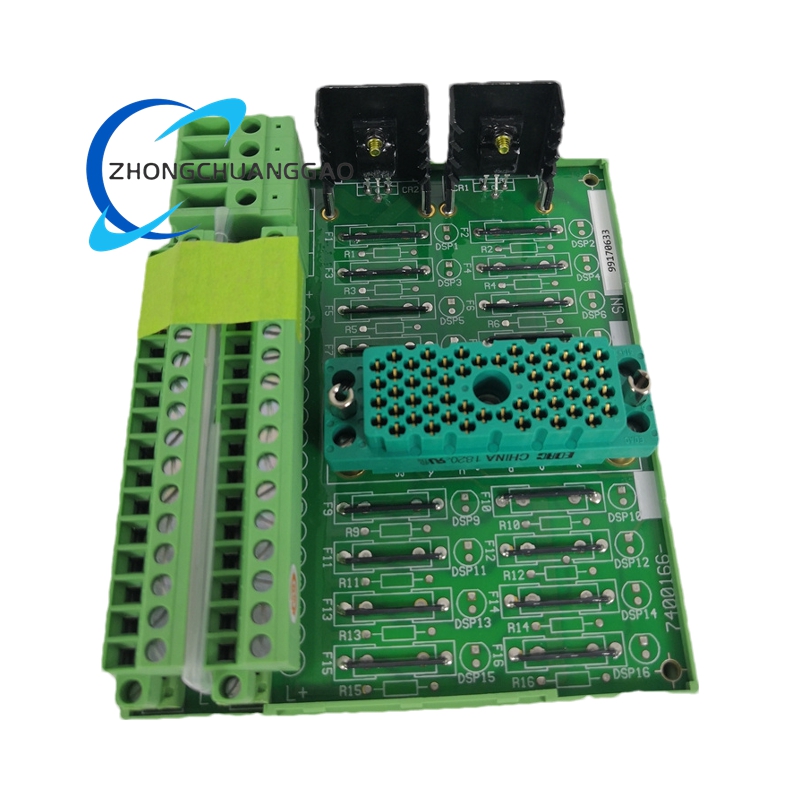

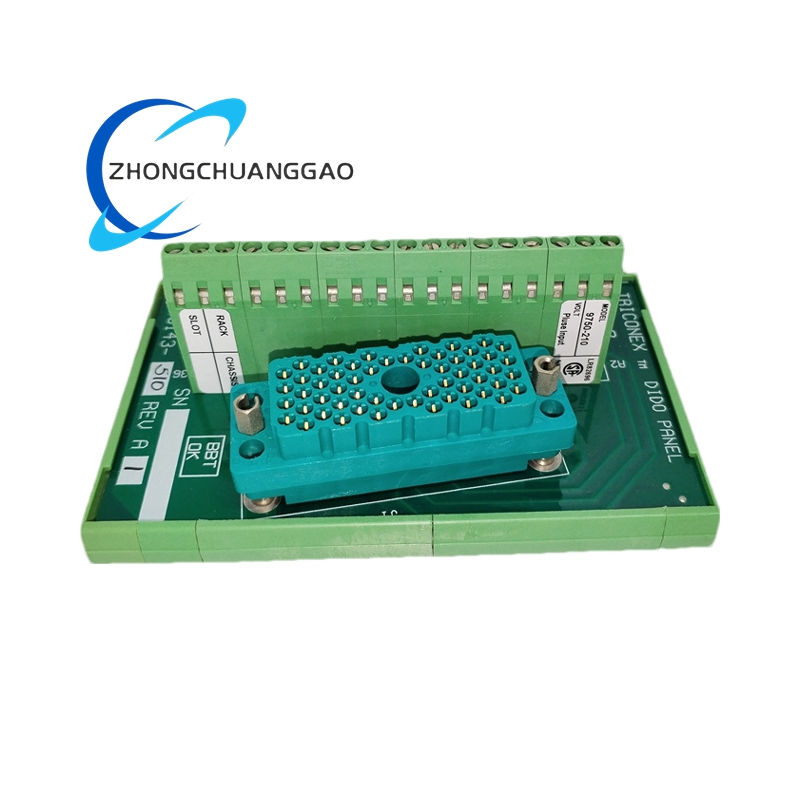

TRICONEX 3000656-210-REVA Fault-Safe I/O Module

Technical Specifications

- Channels: 16 digital input/output channels

- Signal Type: Digital (on/off)

- Voltage Range: 24 VDC

- Current Range: 2 A

- Response Time: ≤2 ms

- Protection Level: IP67 (protection against dust and water immersion)

- Operating Temperature: -40°C to 70°C

- Dimensions: 144 x 64 x 32 mm

- Weight: 0.5 kg

- Mounting Options: DIN rail or panel mounting

TRICONEX 3004 Enhanced TRICONZ Main Processor II with SOE and 1MSRAM

Technical Specifications

- Architecture: Triple Modular Redundant (TMR)

- Memory: 1MSRAM (1 Megabyte of Static Random-Access Memory)

- Functionality: Includes Sequence of Events (SOE) recording for detailed event analysis

- Communication: Supports standard industrial communication protocols for integration with other systems

- Power Requirements: Designed to operate within specified voltage and power consumption ranges typical for industrial control systems

- Environmental: Built to withstand harsh industrial environments with appropriate temperature and humidity ratings

TRICONEX 3000678-110

Technical Specifications

- Redundancy Architecture: Triple Modular Redundant (TMR) design with three independent channels for fault tolerance.

- Safety Standards: Compliant with IEC 61508 SIL 3 and other international safety certifications.

- Input/Output Type: Digital or analog (specific type depends on the exact module variant).

- Operating Temperature: Typically ranges from -40°C to 70°C.

- Enclosure Rating: IP20 or higher for protection against solid objects and dust.

- Mounting Options: DIN rail or panel mounting for easy installation.

- Communication Protocols: Supports standard industrial protocols like Modbus for data exchange.