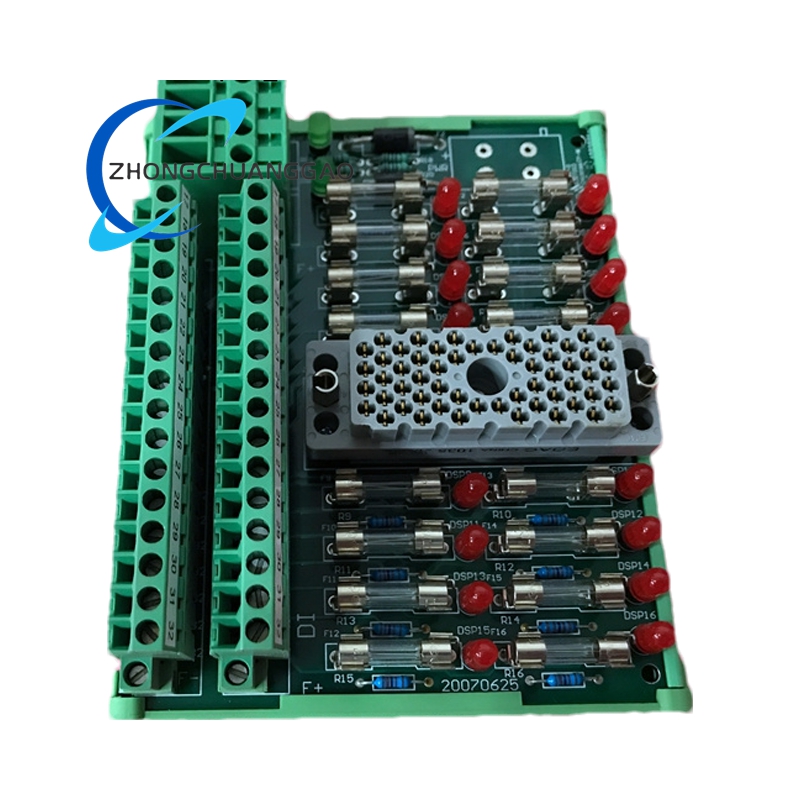

Triconex 4210

Technical Specifications:

- Redundancy Architecture: Triple Modular Redundant (TMR) design for enhanced fault tolerance and system availability.

- Input Channels: 16 digital input channels (24V DC, supporting SOE time stamping).

- Output Channels: 8 digital output channels (relay contacts, rated 250V AC/30V DC).

- Communication Interfaces: 2 Ethernet ports (10/100Mbps), 1 RS-485 port (Modbus RTU).

- Processing Capability: Single-channel scan cycle ≤50ms (under full-channel load).

- Environmental Adaptability: Operating temperature range of -20°C to +70°C; anti-vibration rating of IEC 60068-2-64 (5-500Hz, 5g).

- Power Requirements: DC 24V ±15% (dual power supply redundant input).

- Safety Certifications: IEC 61508 SIL3, TÜV Rheinland, Ex ia IIC T4 Ga (explosion-proof certification).

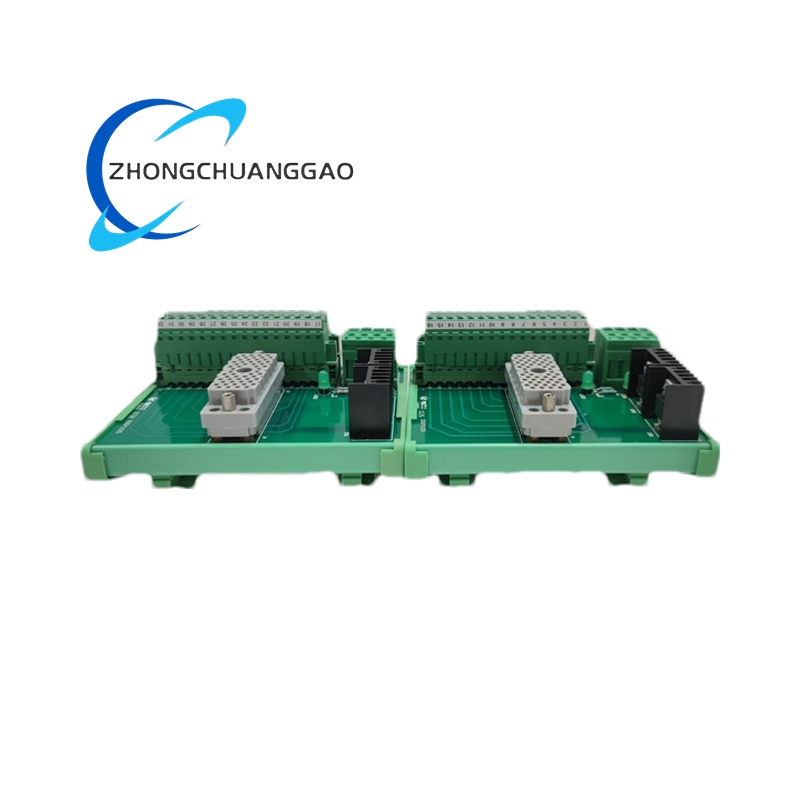

Triconex 4201

Technical Specifications:

- Input Voltage: 24V DC

- Operating Temperature Range: -40°C to 70°C, ensuring reliable operation in extreme conditions.

- Maximum Input/Output Configuration:

- Digital Inputs: Up to 64

- Analog Inputs: Up to 16

- Digital Outputs: Up to 64

- Analog Outputs: Up to 8

- Communication Protocols: Supports various protocols such as Modbus, DNP3, and others for seamless integration with other industrial systems.

- Redundancy: Utilizes triple modular redundancy (TMR) technology to ensure high system availability and fault tolerance.

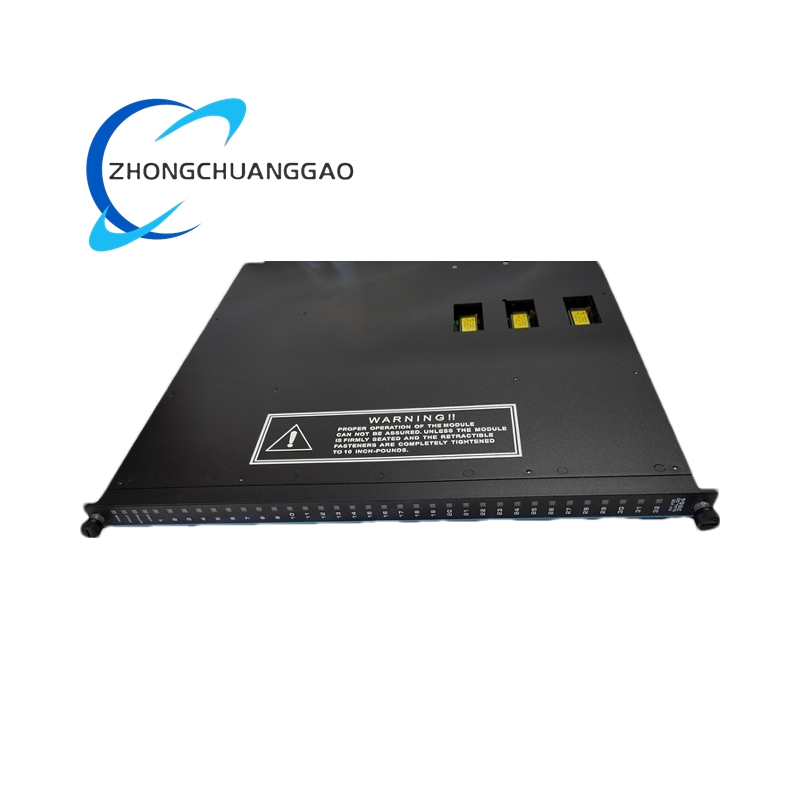

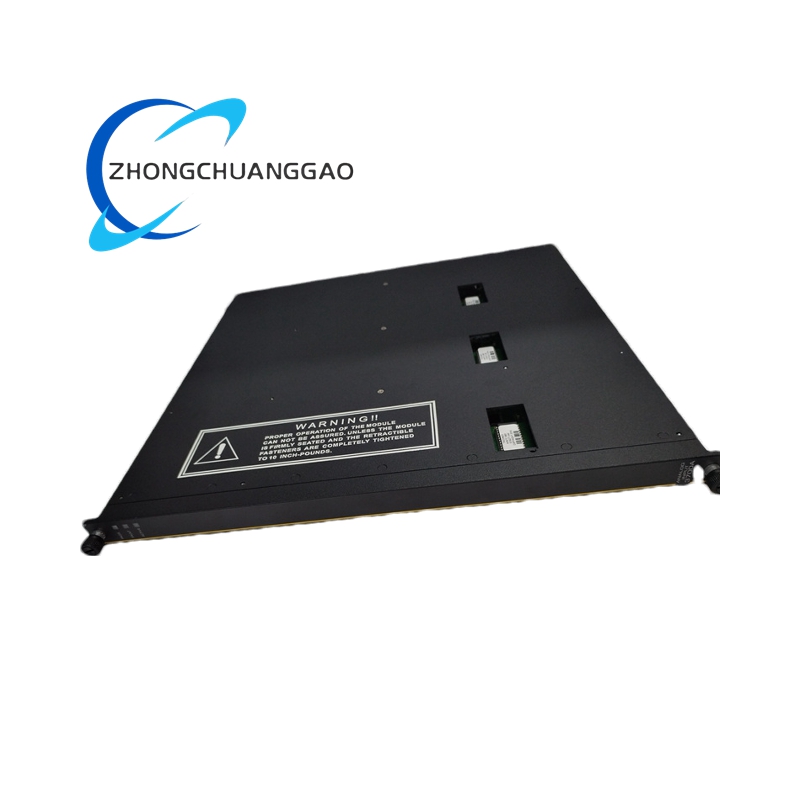

Triconex 4200 Digital Input Module

Technical Specifications:

- Processor: 32-bit RISC processor for high-speed data processing.

- Memory: 128MB RAM, 2GB storage for extensive data logging and program execution.

- Communication Interfaces: RS-232, RS-485, Ethernet for seamless integration with other industrial systems.

- Input Channels: 16 channels, supporting multiple signal types such as dry contacts, wet contacts, NAMUR, PNP/NPN.

- Operating Temperature Range: -40°C to +70°C, ensuring reliable operation in extreme conditions.

- Redundancy Design: Triple Modular Redundancy (TMR) architecture for fault tolerance and high availability.

- Protection Class: IP65, safeguarding against dust and water ingress.

- Dimensions: 225mm x 175mm x 100mm, compact and rugged design for industrial installations.

- Weight: 3kg, facilitating easy handling and mounting.

Triconex 4119

Technical Specifications:

- 4119A Redundancy Power Module:

- Function: Provides redundant power supply for SIS controllers and I/O stations.

- Architecture: Adopts Triple Modular Redundancy (TMR) to ensure continuous operation in case of a single-point failure.

- Compatibility: Easily integrates with existing Triconex systems for seamless expansion and upgrades.

- Enhanced Intelligent Communication Module (EICM):

- Communication Interfaces: Supports multiple communication protocols, such as Ethernet, Modbus, and others, for data exchange with other devices or systems.

- Data Processing: Capable of complex data processing and logical operations to meet various safety control requirements.

- Configuration: Offers flexible configuration options to adapt to different application needs.

Triconex 4104C

Technical Specifications:

- Execution Speed: 0.8 milliseconds, ensuring rapid response to control demands.

- Series: Versamax, indicating its compatibility with a range of systems and its versatility in different applications.

- Lifecycle Status: Active, suggesting that it is currently being produced and supported by the manufacturer.

- Input Voltage: 120/240 volts AC, allowing for flexibility in different power supply environments.

- Output Voltage: 5 volts DC and 3.3 volts DC, providing compatibility with a wide range of devices and systems.

Triconex 4104

Technical Specifications (General for Triconex SIS):

- Architecture: TMR design for enhanced fault tolerance and system availability, ensuring uninterrupted operation.

- Safety Integrity Level (SIL): Certified for SIL 3 applications, indicating the highest level of safety integrity and compliance with international safety standards.

- Processing Capability: Equipped with powerful processing capabilities to rapidly respond to control demands.

- Communication Protocols: Supports various protocols for seamless integration with industrial networks and devices, enabling efficient data exchange.

- Environmental Conditions: Designed to operate reliably in harsh industrial environments, with wide temperature ranges and resistance to vibration and shock.

Triconex 4000212-050

Technical Specifications:

- Architecture: TMR design for enhanced fault tolerance and system availability, ensuring uninterrupted operation.

- Safety Integrity Level (SIL): Certified for SIL 3 applications, indicating the highest level of safety integrity and compliance with international safety standards.

- Processing Capability: Equipped with powerful processing capabilities to rapidly respond to control demands.

- Communication Protocols: Supports various protocols for seamless integration with industrial networks and devices, enabling efficient data exchange.

- Environmental Conditions: Designed to operate reliably in harsh industrial environments, with wide temperature ranges and resistance to vibration and shock.

Triconex 7400212-100

Technical Specifications:

- Architecture: Triple Modular Redundant (TMR) design for enhanced fault tolerance and system availability.

- Safety Integrity Level (SIL): Certified for SIL 3 applications, ensuring compliance with international safety standards.

- Processing Capability: Equipped with powerful processing capabilities to rapidly respond to control demands.

- Programmability: Highly programmable and flexible, allowing users to customize configurations and programming to suit specific application needs.

- Communication Capability: Outstanding communication capabilities for seamless integration with other devices and systems, enabling real-time data transmission and sharing.

Triconex 4000212-002

Technical Specifications:

- Architecture: TMR design for enhanced fault tolerance and system availability, ensuring uninterrupted operation.

- Safety Integrity Level (SIL): Certified for SIL 3 applications, indicating the highest level of safety integrity and compliance with international safety standards.

- Communication Protocols: Supports various protocols for seamless integration with industrial networks and devices, enabling efficient data exchange.

- Environmental Conditions: Designed to operate reliably in harsh industrial environments, with wide temperature ranges and resistance to vibration and shock.

- Certifications: Meets stringent regulatory requirements, providing assurance of safety and compliance in critical applications.

Triconex 4000206-550

Technical Specifications:

- Architecture: TMR design for enhanced fault tolerance and system availability, ensuring uninterrupted operation.

- Safety Integrity Level (SIL): Certified for SIL 3 applications, indicating the highest level of safety integrity and compliance with international safety standards.

- Communication Protocols: Supports various protocols for seamless integration with industrial networks and devices, enabling efficient data exchange.

- Environmental Conditions: Designed to operate reliably in harsh industrial environments, with wide temperature ranges and resistance to vibration and shock.

- Certifications: Meets stringent regulatory requirements, providing assurance of safety and compliance in critical applications.

Triconex 4000206-520

Technical Specifications:

- Architecture: TMR design for enhanced fault tolerance and system availability, ensuring uninterrupted operation.

- Safety Integrity Level (SIL): Certified for SIL 3 applications, indicating the highest level of safety integrity and compliance with international safety standards.

- Communication Protocols: Supports various protocols for seamless integration with industrial networks and devices, enabling efficient data exchange.

- Environmental Conditions: Designed to operate reliably in harsh industrial environments, with wide temperature ranges and resistance to vibration and shock.

- Certifications: Meets stringent regulatory requirements, providing assurance of safety and compliance in critical applications.

Triconex 4000206-510

Technical Specifications:

- Architecture: TMR design for enhanced fault tolerance and system availability, ensuring uninterrupted operation.

- Safety Integrity Level (SIL): Certified for SIL 3 applications, indicating the highest level of safety integrity and compliance with international safety standards.

- Communication Protocols: Supports various protocols for seamless integration with industrial networks and devices, enabling efficient data exchange.

- Environmental Conditions: Designed to operate reliably in harsh industrial environments, with wide temperature ranges and resistance to vibration and shock.

- Certifications: Meets stringent regulatory requirements, providing assurance of safety and compliance in critical applications.