GE M2X-O1-S1-A1-B0-C0-D1-P2-G0-VC0-V0-E0-M0-L2

Product Introduction

The M2X‑O1‑S1‑A1‑B0‑C0‑D1‑P2‑G0‑VC0‑V0‑E0‑M0‑L2 is a high‑performance DGA and moisture monitoring unit designed by GE Vernova for utility and industrial power transformers, serving as a critical component for asset health management. It integrates a single composite gas sensor (measuring H₂, CO, C₂H₂, C₂H₄) and a built‑in moisture sensor to continuously track dissolved fault gases and water content in transformer oil, with readings displayed in %RH and ppm. The unit features a compact, rugged enclosure with no moving parts, reducing maintenance requirements and extending operational lifespan.

GE IS420UCSBH4A

Product Introduction

The IS420UCSBH4A is a high-performance UCSB controller module designed by General Electric for Mark VIe, EX2100e, and LS2100e control systems, serving as the core processing unit for industrial automation and turbine control applications. It is powered by a 1066 MHz Intel EP80579 processor running the QNX Neutrino real-time operating system, delivering deterministic control with microsecond-level task scheduling for critical turbine operations. The module features a compact, rugged design with conformal coating, dual redundant 24 V DC power inputs, and seamless integration with Mark VIe I/O modules via IONet.

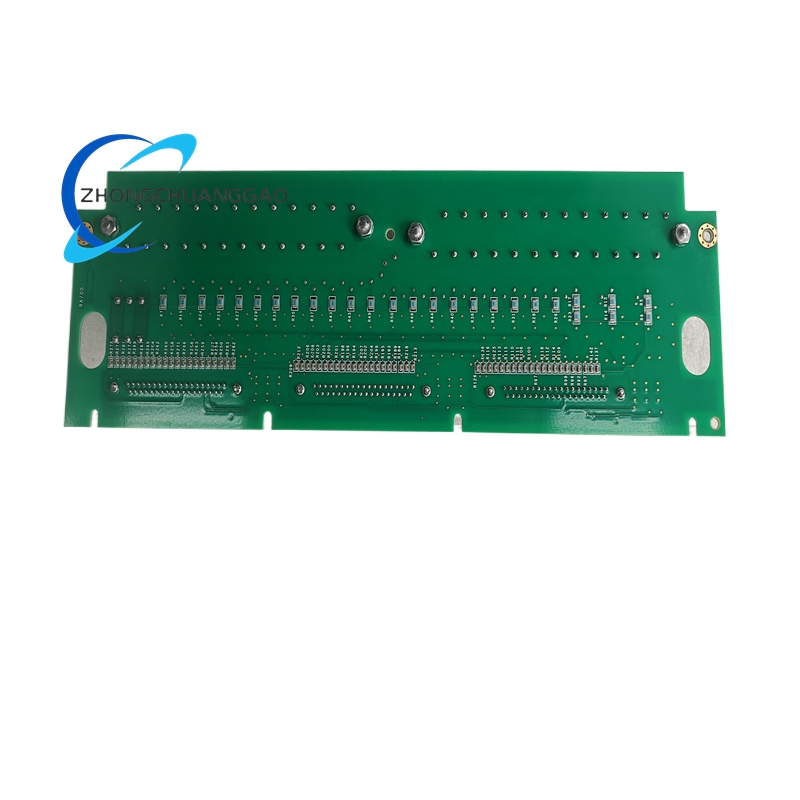

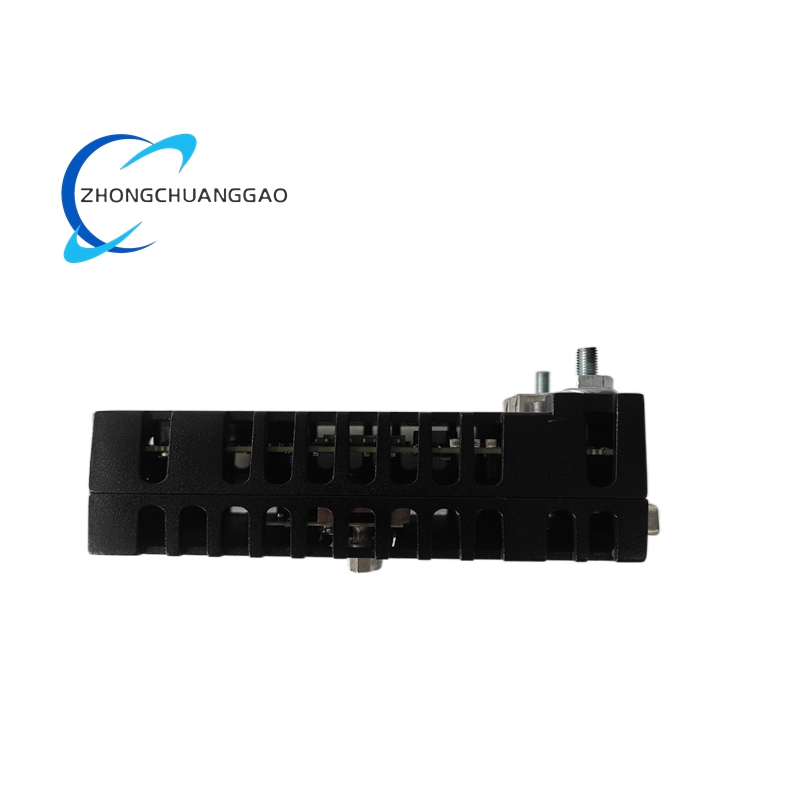

GE IS420TBCIS2C

Product Introduction

The IS420TBCIS2C is a high-reliability discrete input terminal board engineered by General Electric for the Mark VIeS Speedtronic Control System, serving as the interface between field wiring and Mark VIeS I/O modules. It provides 32 channels of isolated contact input termination, each with built-in surge suppression and high-frequency noise filtering to ensure accurate signal acquisition in harsh industrial environments. The board features two terminal blocks (TB1 and TB2) for secure field connection, and integrates seamlessly with Mark VIeS I/O modules (e.g., IS420TBCH1A) to deliver precise discrete input data for turbine control, safety interlocks, and monitoring functions.

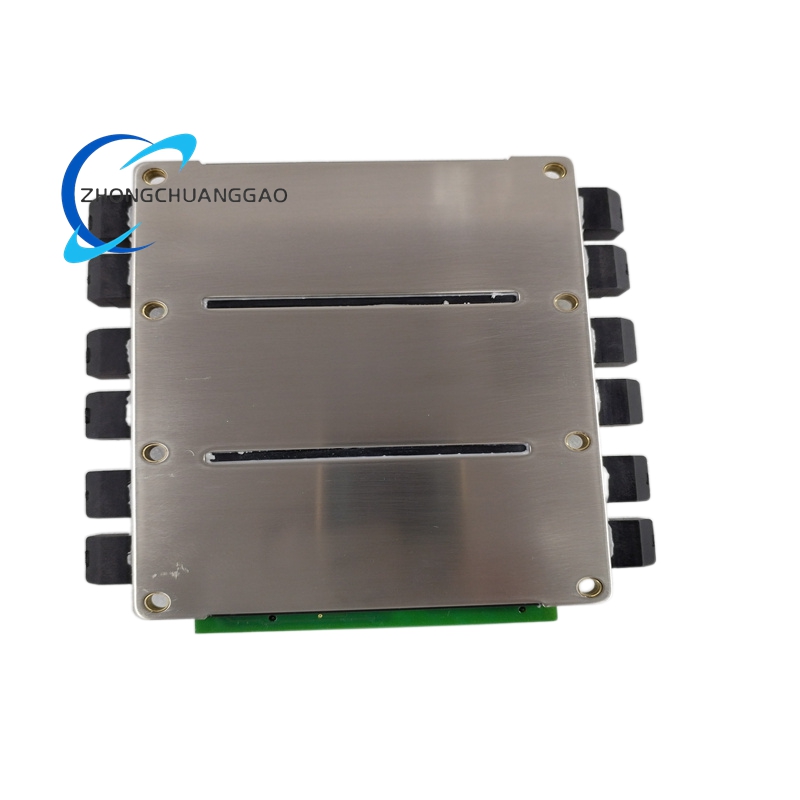

GE IS420ESWBH2A

Product Introduction

The IS420ESWBH2A is a rugged, unmanaged Industrial Ethernet Switch (IONet Switch) developed by General Electric for seamless integration with Mark VIe and Mark VIeS Speedtronic Control Systems. It functions as a core communication hub, offering 16 copper ports and 2 fiber ports to connect controllers, I/O modules, operator interfaces, and auxiliary devices within industrial control networks. The switch uses a store‑and‑forward architecture with a 4K MAC address table and 256 KB buffer memory to ensure deterministic IONet data transfer, critical for real‑time turbine control and safety interlocks. It supports dual redundant 24 V DC power inputs and features conformal coating to withstand harsh industrial environments with extreme temperatures, dust, moisture, and electromagnetic interference.

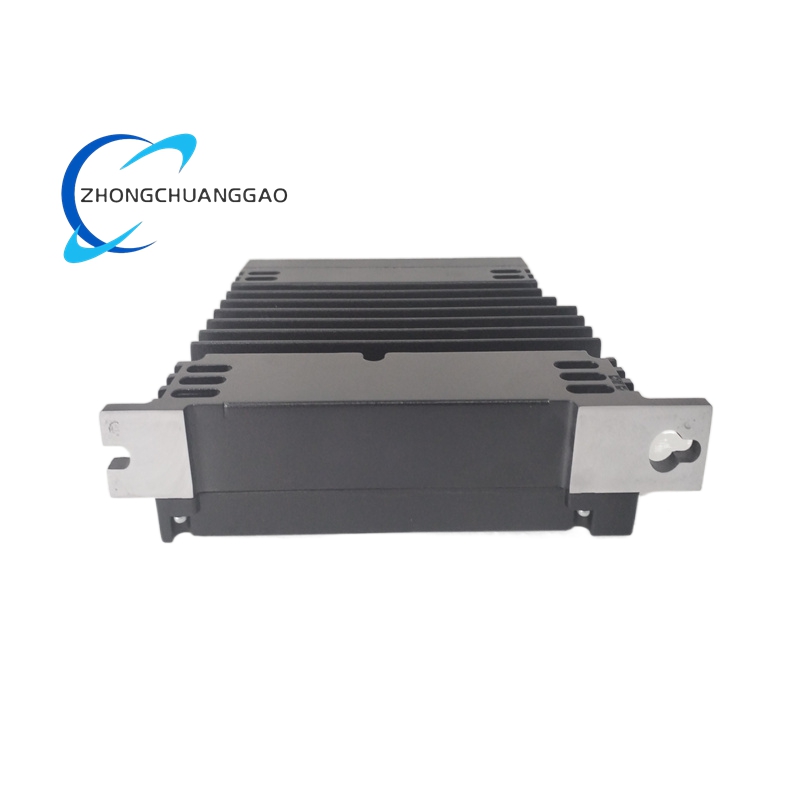

GE IS420ESWAH3A

Product Introduction

The IS420ESWAH3A is a rugged, unmanaged Industrial Ethernet Switch (IONet Switch) engineered by General Electric as a critical communication component for Mark VIe and VIeS Speedtronic Control Systems. It provides deterministic real-time IONet communication between controllers, I/O modules, and operator interfaces, enabling reliable data exchange in mission-critical industrial automation networks. The switch features 8 × 10/100Base‑TX copper ports with auto-negotiation and HP‑MDIX auto-sensing, supporting flexible network topologies with optional 2 × 100Base‑FX multimode fiber ports (LC-type) for long-distance connectivity.

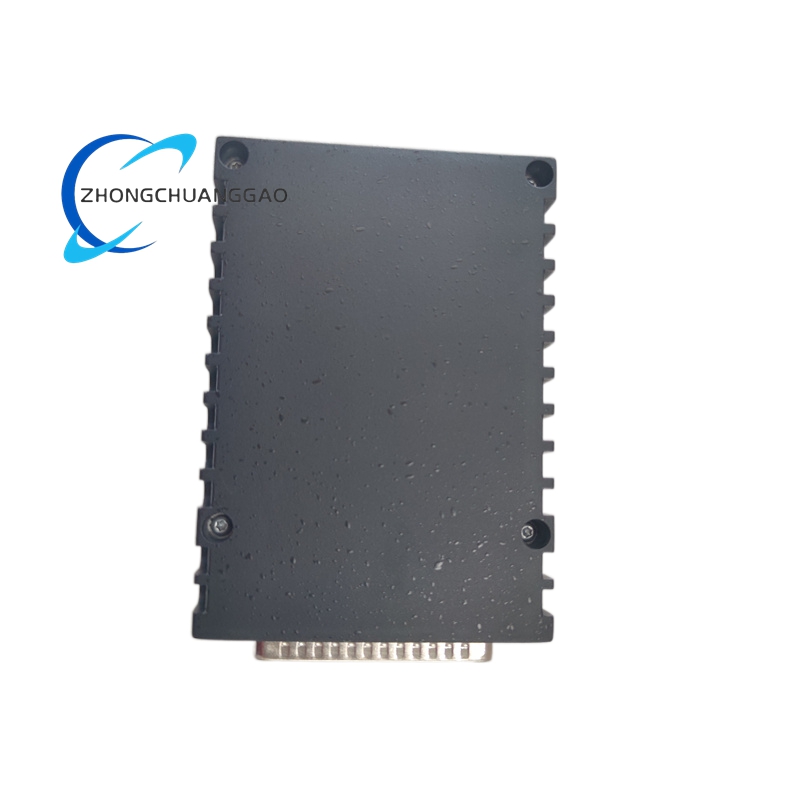

GE IS400AEBMH1AJD

Product Introduction

The IS400AEBMH1AJD is a dedicated Auxiliary Equipment Bus Module (AEBM) from General Electric, serving as a core communication and interface component within the Mark VIe Speedtronic Control Series. It establishes a reliable auxiliary equipment bus for connecting auxiliary devices, I/O modules, and peripheral components to the main Mark VIe control network, facilitating seamless data exchange and power distribution across the system. The module integrates a high-speed communication controller, redundant bus interfaces, and power regulation circuitry, optimized for industrial environments with high electromagnetic interference and temperature fluctuations.

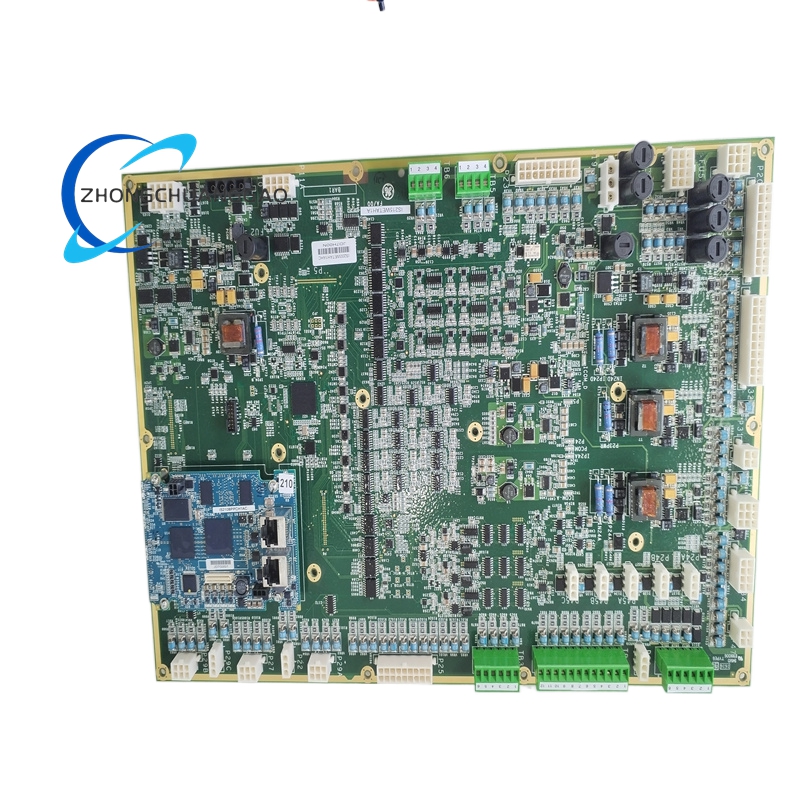

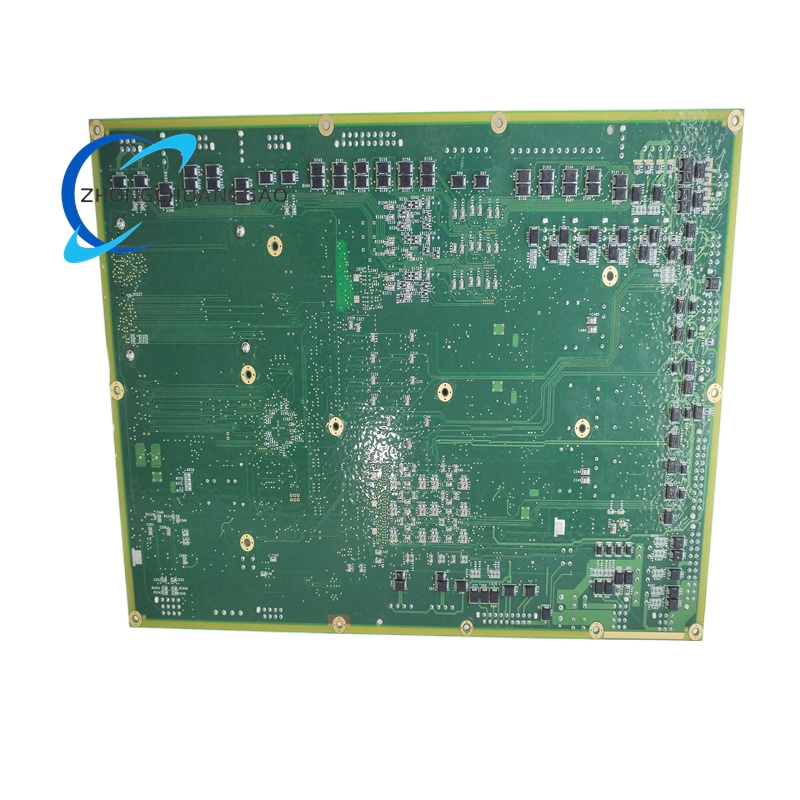

GE IS220UCSAH1A-C

Product Introduction

The IS220UCSAH1A-C is a high-performance Standalone Processor Module (UCSA) engineered by General Electric as a core component of the Mark VIe Speedtronic Control Series, dedicated to delivering centralized control and real-time data processing for industrial automation systems. It serves as a standalone controller running application code, mounting in a panel and communicating with I/O packs through the onboard I/O network (IONet) interfaces, which are private special-purpose Ethernet supporting only I/O modules and controllers. The module is powered by a Freescale PowerPC (Power QUICC II PRO 667 MHz) processor and runs the QNX Neutrino real-time multitasking operating system, designed for high speed, high reliability, and industrial applications.

GE IS220PVIBH1A

Product Introduction

The IS220PVIBH1A is a dedicated Vibration Monitor (PVIB) I/O Pack from General Electric, designed as a core component of the Mark VIe Speedtronic Control Series for real‑time vibration and proximity monitoring of rotating machinery. It serves as the electrical interface between up to two I/O Ethernet networks and the TVBA vibration terminal board, processing data from 13 sensor channels to deliver critical machinery health insights. The module integrates a 32‑bit embedded local processor, a high‑precision data acquisition board, and a daughterboard, all standard across Mark VIe distributed I/O packs.

GE IS220PPROS1B

Product Introduction

The IS220PPROS1B is a Backup Turbine Protection I/O Pack developed by General Electric as a core component of the Mark VIe Speedtronic Control Series, dedicated to delivering redundant safety protection for gas and steam turbines in critical industrial settings. It functions as a backup protection module, working in tandem with the primary PTUR (Turbine Primary I/O Pack) to monitor turbine speed, acceleration, and emergency trip signals, and initiate shutdown procedures when abnormal conditions occur. The module features a 32‑bit embedded processor, dual redundant Ethernet ports for IONet communication, and a rugged design with conformal coating to withstand harsh industrial environments.

GE IS220PPRFH1B

Product Introduction

The IS220PPRFH1B is a PROFIBUS Master Gateway I/O Module developed by General Electric as part of the Mark VIe Speedtronic Control Series, acting as a critical communication bridge between Mark VIe controllers and PROFIBUS DP field devices. It functions as a PROFIBUS DPV0 and Class 1 master, mapping I/O data from PROFIBUS slaves to the Mark VIe I/O Ethernet for seamless integration into turbine control and industrial automation systems. The module features a Hilscher COM‑C PROFIBUS communication module with an RS‑485 interface, dual redundant Ethernet ports, and a 32‑bit embedded processor optimized for real‑time data transfer.

GE IS215WETAH1A

Product Introduction

The IS215WETAH1A is a Wind Energy Top Box A (WETA) Module developed by General Electric for the Mark VIe Wind Turbine Control Series, serving as a key control and monitoring component in wind turbine top box assemblies. It integrates core control logic for turbine operation management, safety interlocks, and communication with main cabinets, pitch control systems, and SCADA networks. The module processes real-time data from wind speed sensors, rotor speed encoders, generator output monitors, and safety relays to optimize energy capture and ensure safe turbine operation. It features a rugged design with conformal coating to withstand harsh environmental conditions, including extreme temperatures, humidity, and vibration, typical of onshore and offshore wind farm installations.

GE IS215WEPAH2B 109W3914P003

Product Introduction

The IS215WEPAH2B (109W3914P003) is a Wind Energy Pitch Axis (WEPA) Board from General Electric, a dedicated control component for Mark VIe Speedtronic wind turbine control systems. It serves as the core module for wind turbine blade pitch axis control, executing real-time pitch angle adjustments based on wind speed, rotor speed, and blade position data to optimize energy capture and ensure safe turbine operation. The board integrates analog and digital I/O, encoder interfaces, and communication ports to interact with pitch drive units, main controllers, and safety systems. It features a rugged design with conformal coating for reliable performance in harsh wind farm environments, including extreme temperatures, humidity, and vibration.