GE IS215WEMAH1A

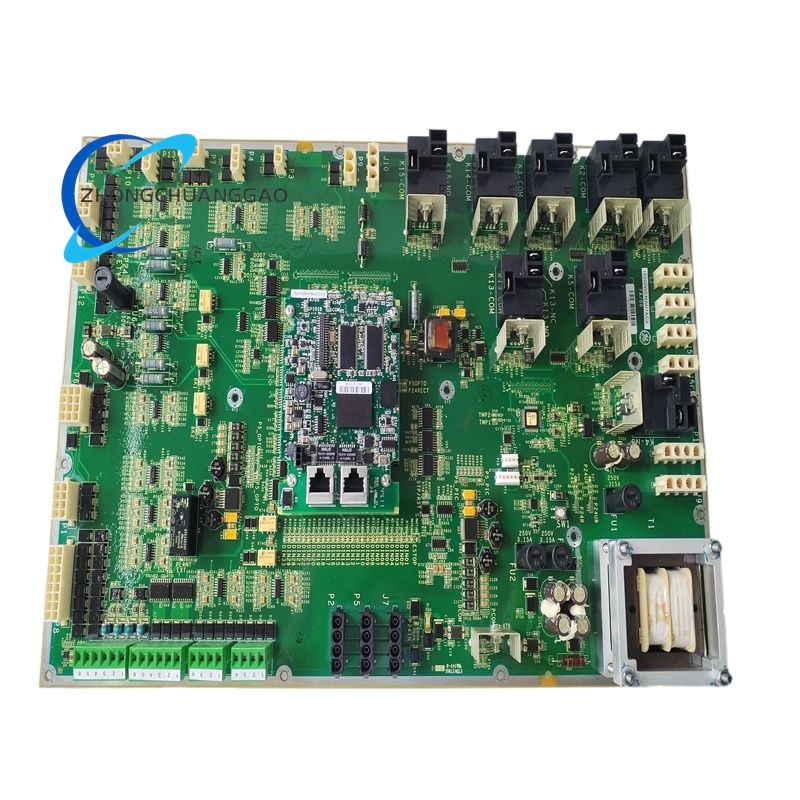

Product Introduction

The IS215WEMAH1A is a WEMA and BPPS Board Assembly developed by General Electric for the Mark VIe Wind Turbine Control Series, serving as a central control and monitoring component in wind turbine main cabinets. It integrates core control logic for blade pitch positioning, turbine operation management, and safety interlocks, while facilitating seamless communication with other wind turbine subsystems such as the main controller, pitch drive units, and SCADA systems. The board processes real-time data from wind speed sensors, rotor speed encoders, blade angle sensors, and generator output monitors to optimize energy capture and ensure safe turbine operation.

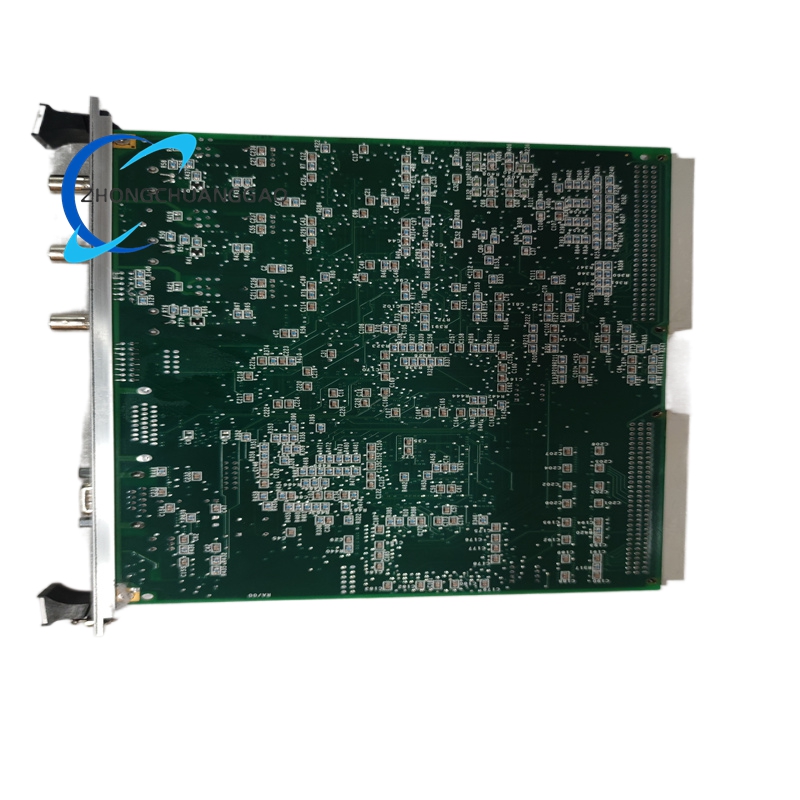

GE IS215VCMIH2C

Product Introduction

The IS215VCMIH2C is a VME Communication Interface (VCMI) Board from General Electric, a core communication component for Mark VI Speedtronic turbine control systems. It acts as the VME bus master in control and I/O racks, managing board IDs and terminal board associations, and enabling high-speed data exchange across the VME backplane, expansion racks, backup protection modules, and triple modular redundancy (TMR) control processors. It serves as the central communication intermediary between distributed I/O hardware and the main controller while maintaining connectivity to the IONet control network, supporting both simplex and TMR architectures.

GE IS215UCVEM08B

Product Introduction

The IS215UCVEM08B is a US2000 Processor Board developed by General Electric as a core processing component for Mark VI Speedtronic turbine control systems, specifically designed for gas and steam turbine applications. It integrates an Intel Celeron processor, memory modules, and communication interfaces to execute real-time control logic, process sensor data, and coordinate with other system modules. It operates on the QNX real-time operating system, ensuring deterministic performance for critical turbine control functions such as speed regulation, load management, and safety interlocks.

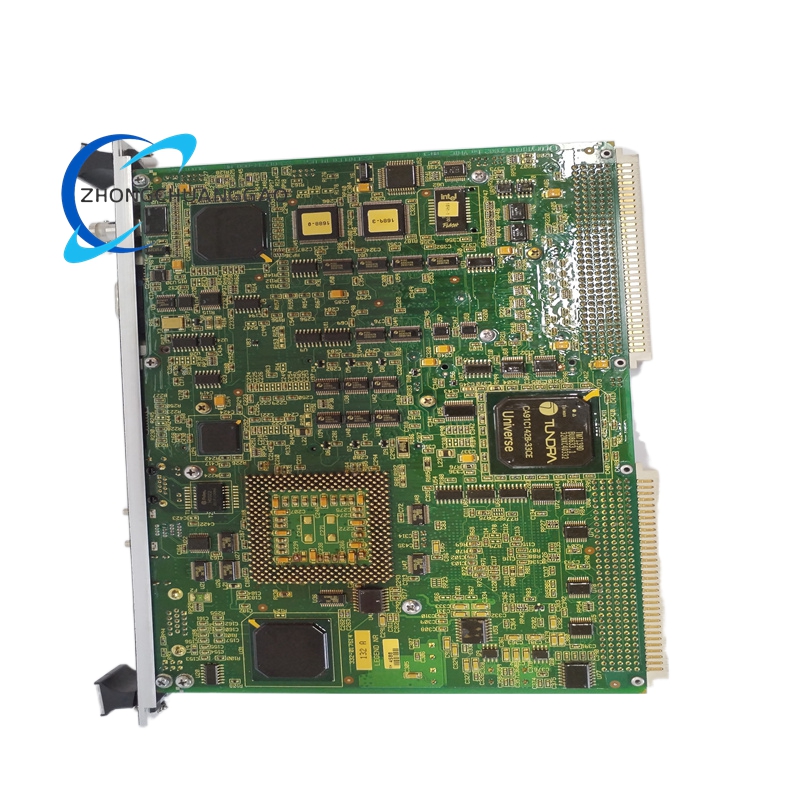

GE IS215UCVEH2AE

Product Introduction

The IS215UCVEH2AE is a single‑slot VME CPU controller card developed by General Electric, specifically designed for the Mark VI Speedtronic turbine control system and also compatible with the EX2100 series industrial automation system. As a core central processing unit (CPU) component, it executes complex control logic operations, collects critical parameters of industrial equipment, performs signal conversion and transmission, and monitors equipment status. It coordinates communication with other I/O modules within the system to ensure stable and efficient operation of large rotating machinery such as steam turbines and gas turbines.

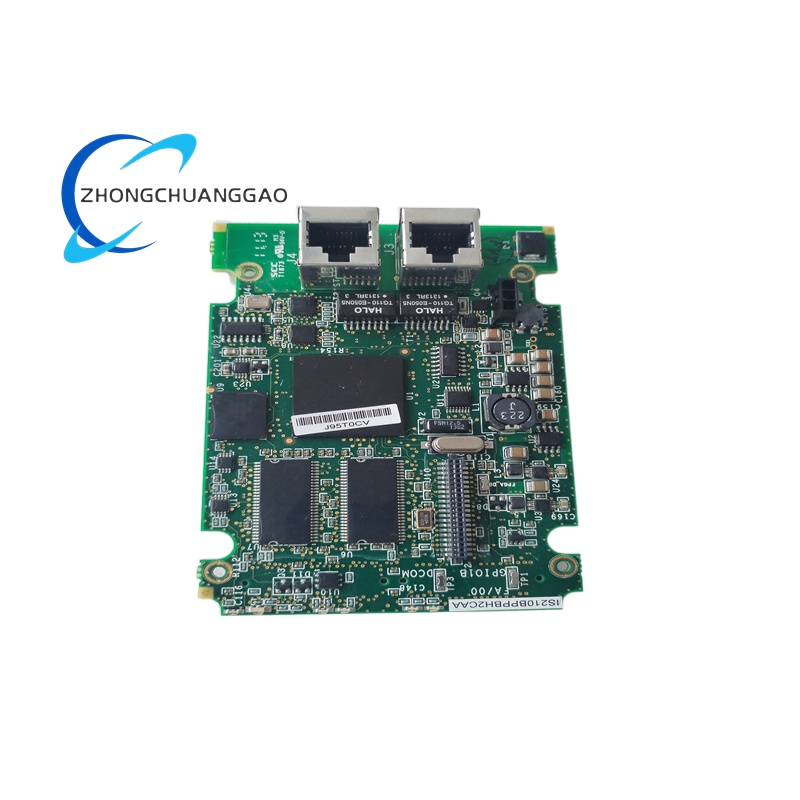

GE IS210BPPBH2CAA

Product Introduction

The IS210BPPBH2CAA is a Backup Protection Processor Board (BPPB) engineered by General Electric specifically for the Mark VI turbine control system. It serves as a core component for executing turbine application software, handling protection algorithms, sequencing, I/O display, and operator interface functions in both steam and gas turbine control setups. It supports triple modular redundancy (TMR) or simplex configurations, ensuring high reliability and availability in critical power generation applications. The board integrates seamlessly into VME rack-based Mark VI systems, working in tandem with other control modules to process sensor data, execute control logic, and provide backup protection in case of primary control module failures.

GE IS210AEBIH3BED

Product Introduction

The IS210AEBIH3BED is an enhanced AE Bridge Interface Card (AEBI) engineered by General Electric specifically for the Mark VIe Wind Series turbine control systems. It acts as a critical communication and signal-routing bridge between on-tower Automation Equipment (AE) modules and the central Mark VIe controller, enabling seamless real-time data exchange for precise turbine control and monitoring. As a functional variant “3BED” within the IS210AEBIH series, it builds on previous models with optimized communication redundancy, expanded I/O capacity, and advanced diagnostic capabilities while maintaining full compatibility with existing Mark VIe infrastructure.

GE IS210AEBIH3BEC

Product Introduction

The IS210AEBIH3BEC is a high - performance AE Bridge Interface Card engineered by General Electric for the Speedtronic Mark VIe Wind Series turbine control systems. It serves as a pivotal communication and signal - routing bridge, enabling seamless real - time data exchange between on - tower AE (Automation Equipment) modules and the central Mark VIe controller, which is essential for precise turbine control and monitoring. This card is a functional enhanced variant of the IS210AEBIH series, boasting improved communication stability, expanded I/O capacity, and advanced diagnostic features, all while maintaining compatibility with existing Mark VIe infrastructure.

GE IS210AEBIH1B AE Bridge Interface Card for Mark VIe Wind Turbine Control Systems

Product Introduction

The IS210AEBIH1B is a specialized AE Bridge Interface Card designed by General Electric for the Mark VIe Wind Series turbine control systems. It functions as a critical communication and signal - routing bridge between the turbine’s on - tower AE (Automation Equipment) modules and the central Mark VIe controller, enabling seamless data exchange for real - time control and monitoring. The board features conformal coating to protect against moisture, dust, and corrosion, making it suitable for harsh wind farm environments, including offshore and onshore installations. As a functional revision “B” of the base IS210AEBIH1 board, it incorporates enhanced communication stability and diagnostic capabilities without compromising form factor or durability. It supports simplex and redundant Mark VIe configurations, ensuring reliable operation and minimizing downtime in wind energy applications.

GE IS200WETBH1B 104W5259P002

Product Introduction

The IS200WETBH1B is a Top Box B Assembly (WETB) printed circuit board (PCB) designed by GE Energy for the Mark VIe Wind Series turbine control systems. It serves as a critical interface and control module within the wind turbine’s top - of - tower (ToT) control enclosure, managing communication between the turbine’s on - tower sensors, actuators, and the central Mark VIe controller. The board integrates multiple I/O interfaces, power management circuits, and diagnostic features to ensure reliable operation in the harsh environmental conditions typical of wind farms, including extreme temperatures, humidity, and vibration.

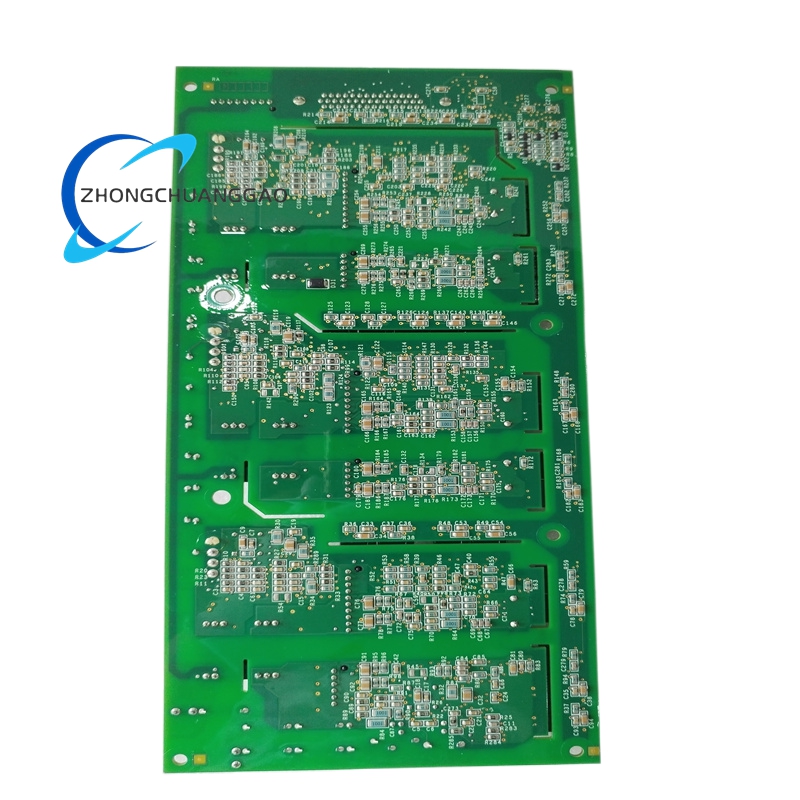

GE IS200TVBAH2ACC Analog Input Termination Board (TVBA) for Mark VI Speedtronic Systems

Product Introduction

The IS200TVBAH2ACC is a high - performance Analog Input Termination Board produced by General Electric, and it is a core I/O component in the Mark VI Speedtronic series for gas and steam turbine control systems. It serves as a crucial interface between field analog sensors/transmitters and the Mark VI controller, responsible for precise acquisition, conditioning, and termination of 16 - channel analog signals. The board supports multiple signal types such as 4 - 20 mA current loops and 0 - 10 VDC voltage signals, and is equipped with 16 - bit A/D conversion and hardware filtering to guarantee accurate and stable data transmission in harsh industrial environments.

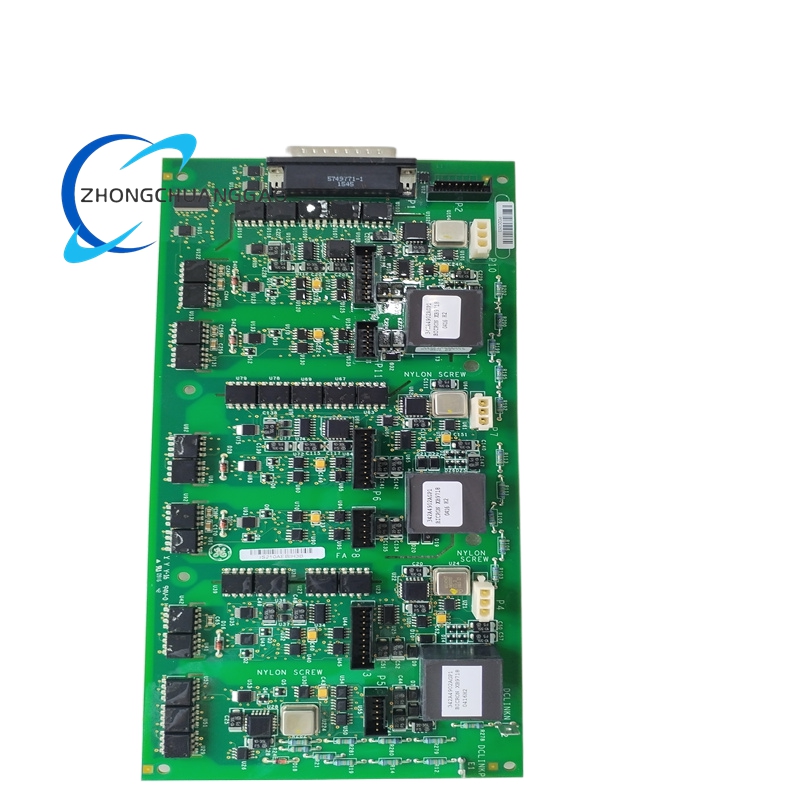

GE IS200TRLYS1B Relay Output Terminal Board (TRLY)

Product Introduction

The IS200TRLYS1B is a Relay Output Terminal Board manufactured by General Electric, designed specifically for the Mark VI Speedtronic series of gas and steam turbine control systems. It functions as a critical interface between the Mark VI control system and external field devices, providing reliable relay-based output signal termination and switching for discrete control applications. The board features 12 Form C (changeover) magnetic relays with integrated coil diagnostics, enabling precise and secure control of industrial actuators, valves, motors, and alarms. It supports seamless integration with VME-based Mark VI systems, operating in simplex, dual-redundancy, and triple-redundancy (TMR) configurations to ensure operational integrity in harsh industrial environments.

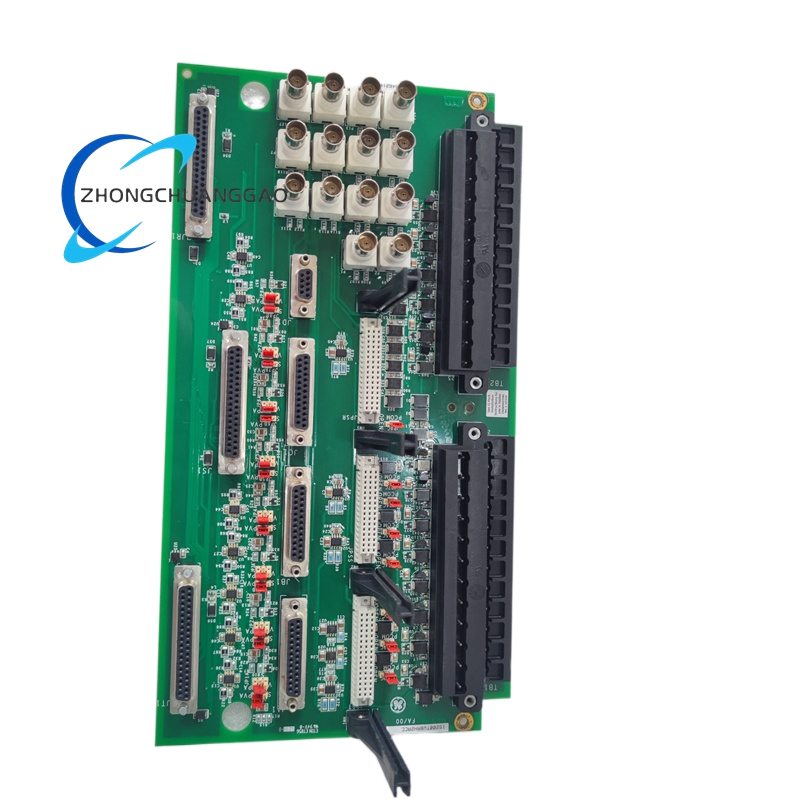

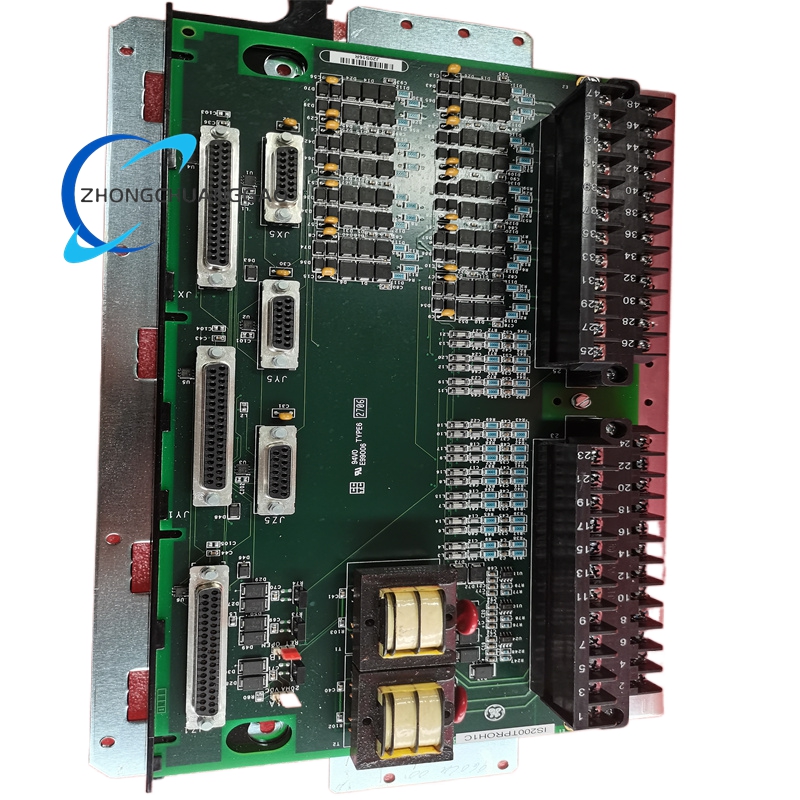

GE IS200TPROH1C Emergency Protection Terminal Board (TPRO)

Product Introduction

The IS200TPROH1C is an Emergency Protection Terminal Board developed by GE, serving as a core component of the Mark VI Speedtronic series for gas and steam turbine control systems. It integrates three PPRO (Protective Processor) I/O packs, a pair of potential transformers (PTs) for bus/generator voltage input, and speed signal conditioning circuitry to ensure reliable monitoring and protection in industrial control environments. This board enables seamless integration with Mark VIe backup trip relay terminal boards via DC - 37 pin connectors, supporting both simplex and Triple Modular Redundancy (TMR) configurations. It plays a vital role in emergency shutdown, overspeed protection, and fault - tolerant operation of turbines, maintaining system integrity in harsh industrial settings.