GE IC697CPX928-FE

- Product Overview: Single-slot CPU module for GE Series 90-70 PLC systems, equipped with a 96MHz 80486DX4 microprocessor, 6MB battery-backed RAM, and 256KB non-volatile user flash memory. It delivers 0.4µs per Boolean function execution, supports 12K mixed I/O and 8K analog I/O, and offers 3 serial ports (1 RS232, 2 RS485) plus a factory reset port. Controlled via a 3-position run/stop switch or software, it uses 7 LEDs for status monitoring and is configured entirely via software.

- Technical Specifications - Processor: 80486DX4 microprocessor, 96MHz clock speed, 0.4µs per Boolean function execution, 32-bit instruction set, 32-bit floating-point support

GE IC697CHS770

- Product Overview: A 17-slot rear-mount rack for GE Series 90-70 PLCs, supporting IC697 PLC modules and IC687 VME I/O/communication modules. It accepts plug-in AC/DC or DC IC697 power supplies, works with external supplies via adaptors, and enables redundancy with IC687 redundancy comms and bus transmitters. It has a 5 VDC backplane, 17 standard 0.8-inch slots, and is certified for industrial use.

- Technical Specifications - Slot Configuration: 17 standard slots, 0.8-inch spacing

- Technical Specifications - Mounting Style: Rear-mount, fits standard 19-inch racks

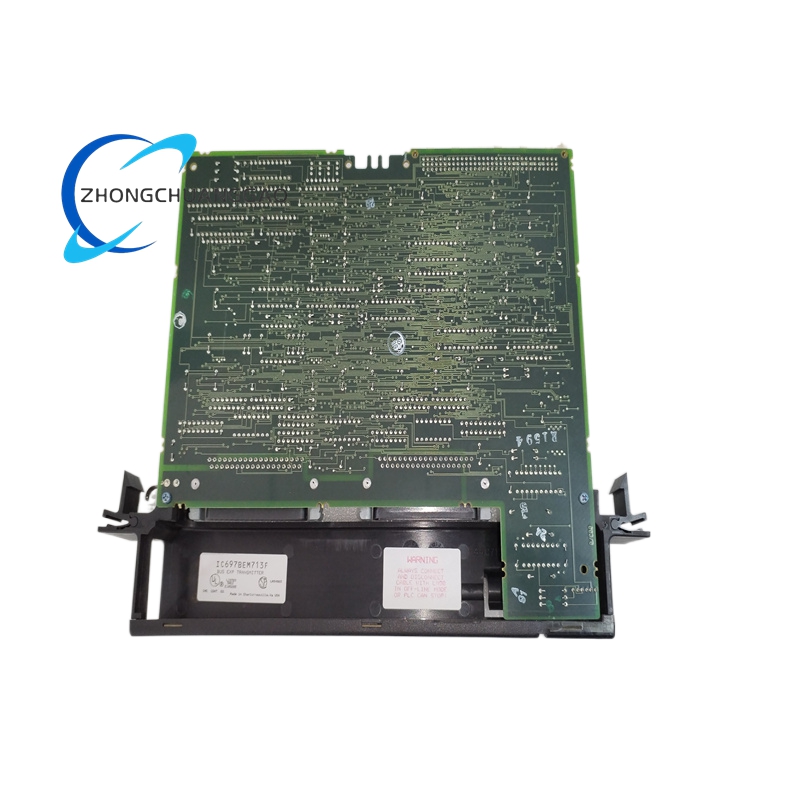

GE IC697BEM713

- Product Overview: A single-slot Bus Transmitter Module for GE Series 90-70 PLCs, installed in the main CPU rack to drive parallel bus expansion to up to 7 Bus Receiver (IC697BEM711) expansion racks. It provides a high-performance parallel programming port and an expansion port for daisy-chaining, with 500 Kbytes/sec data transfer and 15m (50 ft) max cable distance. It uses software configuration, has 3 status LEDs, and requires +5 VDC backplane power.

- Technical Specifications - Form Factor: Single slot, weight 0.85 lbs (0.38 kg), shielded metal enclosure

- Technical Specifications - Installation Slot: Main CPU rack (Slot 2 recommended, Slot 1-4 allowed)

GE IC697BEM711

- Product Overview: A single-slot Bus Receiver Module for GE Series 90-70 PLCs, enabling high-speed parallel bus expansion from the main CPU rack to up to 7 expansion racks with 500 Kbytes/sec data transfer and 15m (50 ft) cable distance. It must be installed in Slot 1 of each expansion rack, uses software configuration (no DIP switches), supports output hold-last-state on CPU loss, and requires the IC697ACC702 terminator in the last rack.

- Technical Specifications - Form Factor: Single slot, weight 1.06 lbs (0.48 kg), shielded metal enclosure

- Technical Specifications - Slot Requirement: Must be installed in Slot 1 of Series 90-70 racks

GE IC695PSD140B

- Product Overview: A single-slot, 40W DC-input power supply for GE PACSystems RX3i Universal Backplanes, supporting load-sharing and redundancy with up to 3 additional IC695PSD140 modules. It delivers +3.3 VDC, +5.1 VDC, and +24 VDC relay outputs to power RX3i modules, relay circuits, and internal logic, with 18-30 VDC input and 60W max input power, and no input-to-backplane isolation.

- Technical Specifications - Form Factor: Single slot, weight 0.70 lbs (0.32 kg), shielded metal enclosure

- Technical Specifications - Input Voltage: 18–30 VDC (24 VDC nominal)

GE IC695PSA040K

- Product Overview: A 2 - slot universal power supply module for GE PACSystems RX3i controllers, delivering three regulated DC outputs (+3.3 VDC, +5.1 VDC, +24 VDC relay) with a total output power of 40 Watts, and a maximum input power of 70 Watts at full load. It supports 85 - 264 VAC or 100 - 300 VDC input, operates on 47 - 63 Hz AC frequency, and is installed in the RX3i Universal Backplane. It offers comprehensive protection features and status LEDs, and is designed for non - redundant single - supply systems.

- Technical Specifications - Form Factor: 2 - slot module, weight 2.65 lbs (1.2 kg), shielded metal enclosure, dimensions 3.60 x 12.11 x 5.72 in (91.4 x 307.5 x 145.3 mm)

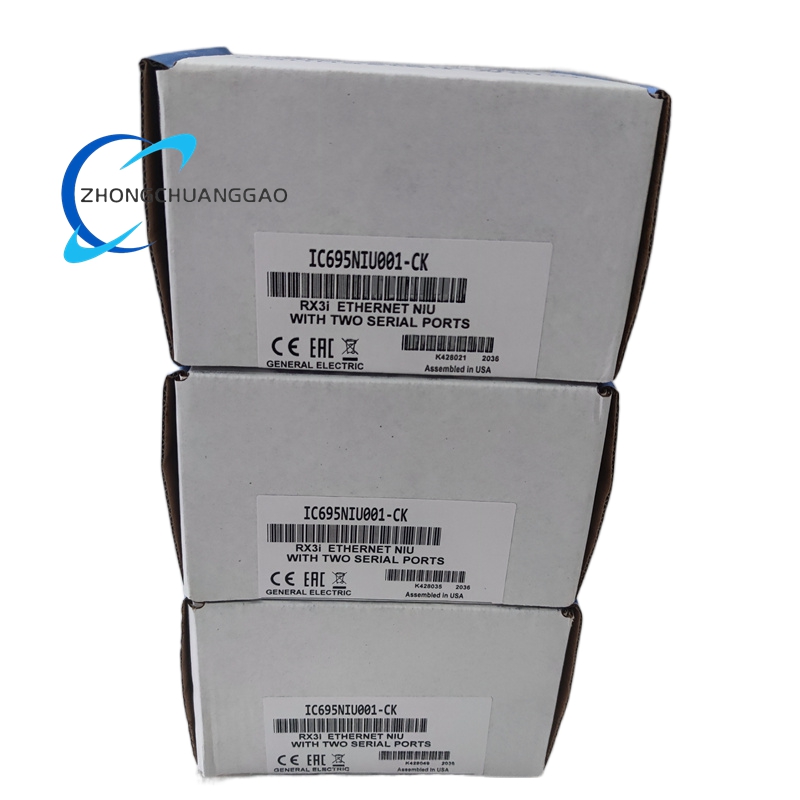

GE IC695NIU001-CK

- Product Overview: A single - slot Ethernet Network Interface Unit (NIU) for GE PACSystems RX3i controllers, enabling remote use of RX3i and Series 90 - 30 I/O over Ethernet networks. It integrates 2 serial ports (RS - 232 and RS - 485), 10 MB flash memory, a battery - backed real - time clock, and works with the backplane - based IC695ETM001 Ethernet Interface Module (EIM). It supports SRTP, Modbus TCP, EGD, and SNP protocols, and operates with redundant controllers, with in - system firmware upgrades and station management tools for diagnostics.

- Technical Specifications - Form Factor: Single - slot module, weight 1.00 lbs (0.45 kg), shielded metal enclosure

GE IC695ETM001ER

- Product Overview: A single - slot Ethernet interface module designed for GE PACSystems RX3i controllers, featuring a 200 MHz Ethernet processor, two auto - sensing 10/100 Mbps RJ - 45 ports, and an embedded Ethernet switch for daisy - chaining nodes. It connects RX3i controllers to Ethernet networks, enabling communication with other PACSystems, Series 90, and VersaMax controllers via SRTP, Modbus TCP, and Ethernet Global Data (EGD) protocols over a TCP/IP stack. It supports one MAC and one IP address, offers in - system firmware upgrades, and includes an RS - 232 Station Manager port for on - line supervision.

- Technical Specifications - Processor: 200 MHz dedicated Ethernet processor

GE IC695CRU320

- Product Overview: A dual - slot redundancy CPU module in GE Fanuc's PACSystems RX3i series, featuring an Intel Celeron - M 1.0 GHz microprocessor, 64 MB battery - backed user RAM and 64 MB non - volatile flash memory. It supports hot standby redundancy with a switchover time of minimum 3.133 ms and maximum 1 logic scan, and works with IC695RMX128/228 redundancy memory exchange modules to ensure seamless failover in critical industrial control systems. It is compatible with Series 90 - 30 modules and RX3i expansion racks, supporting multiple programming languages and serial protocols.

- Technical Specifications - Microprocessor: Intel Celeron - M microprocessor, 1.0 GHz clock speed

GE IC695CPU320

- Product Overview: A high - end central processing unit module of GE's PACSystems RX3i series, equipped with an Intel Celeron - M 1.0 GHz microprocessor, 64 MB battery - backed user RAM and 64 MB non - volatile flash memory. It is designed for complex industrial automation control tasks, supporting multiple programming languages and communication protocols, and is compatible with Series 90 - 30 modules and RX3i expansion racks.

- Technical Specifications - Microprocessor: Intel Celeron - M microprocessor, 1.0 GHz clock speed

- Technical Specifications - Memory: 64 MB battery - backed user RAM, 64 MB non - volatile flash memory

GE IC695CPU315 PACSystems RX3i 1.0 GHz CPU Module

- Product Overview: A high - performance CPU module in GE Fanuc's PACSystems RX3i series, equipped with an Intel Celeron - M 1.0 GHz microprocessor, 20 MB battery - backed user RAM and 20 MB non - volatile flash memory. It is designed for real - time control of industrial automation systems, supporting multiple programming languages and serial protocols, and can be used for complex motion, discrete and analog processing tasks.

- Technical Specifications - Microprocessor: Intel Celeron - M microprocessor, 1.0 GHz clock speed

- Technical Specifications - Memory: 20 MB battery - backed user RAM, 20 MB non - volatile flash memory

GE IC695CPU310-GV

- Product Overview: A high - performance central processing unit module belonging to GE's PACSystems RX3i series, featuring an Intel Celeron (Pentium III) 300 MHz microprocessor. It is designed for real - time control of industrial automation systems, supporting various programming languages and multiple communication protocols, with a firmware version 5.70 that enables functional support for the IC695RMX128 module equivalent to the IC695CMX128.

- Technical Specifications - Microprocessor: Intel Celeron (Pentium III) microprocessor, 300 MHz clock speed

- Technical Specifications - Memory: 10 MB battery - backed user RAM, 10 MB non - volatile flash memory