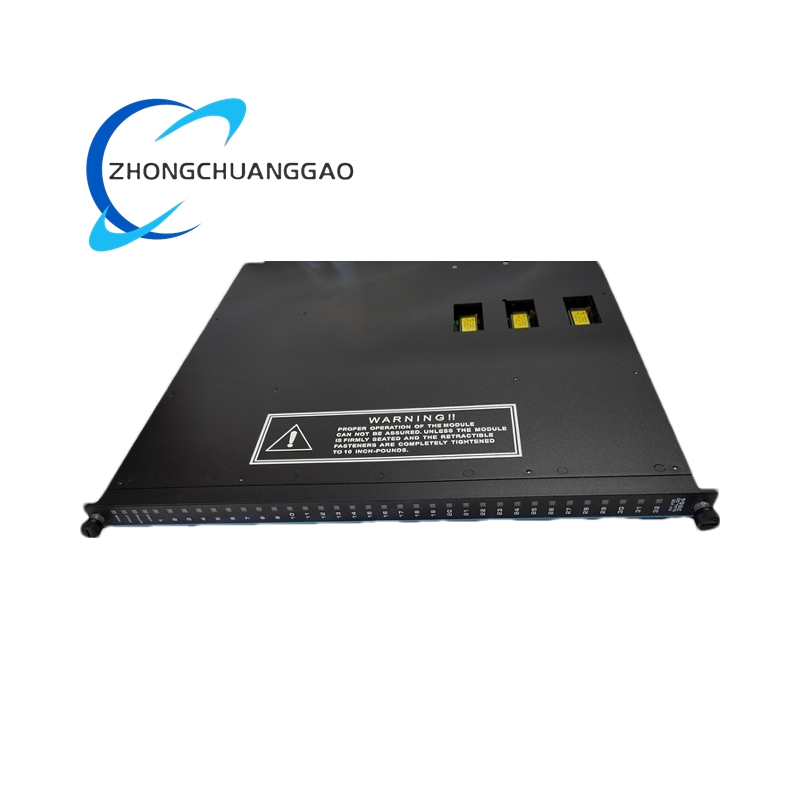

ICS Triplex T8240 Trusted Power Shelf

Technical Specifications

-

Mechanical Specifications

- Form Factor: 19‑inch EIA‑310 rack‑mount; 1U (43 mm) height

- Slot Capacity: 3 hot‑swap bays for T8231C Power Packs

- Dimensions (H×W×D): 43 mm × 483 mm × 340 mm (1.71 in × 19 in × 13.36 in)

- Weight: 3.2 kg (7.05 lbs) (empty); 9.3 kg (20.5 lbs) with 3 T8231C modules

- Mounting: Flange‑mount brackets included for standard 19‑inch racks

- Front Panel: 3 slot indicators (per slot: input OK, output OK, fault); global system OK LED; load‑sharing status LED

- Backplane: Shared 24 VDC output bus; redundant power distribution board; 1500 VDC input‑output isolation

- Material: Steel chassis with powder‑coated finish (industrial grey); UL 94 V‑0 rated plastic front panel

-

Electrical Specifications

- Output Bus: 24 VDC regulated (via T8231C modules); supports up to 2250 W total output (3 × 750 W)

- Load Sharing: Automatic current balancing between power packs (±5% load distribution accuracy)

- Isolation: 1500 VDC input‑to‑output (per T8231C); 500 VDC output‑to‑chassis

- Protection: Overcurrent (31 A per slot), overvoltage (27 VDC bus threshold), short‑circuit (current‑limited, auto‑recover)

- Power Distribution: Redundant bus bars with screw‑locked terminal blocks for T8100 chassis connection

- Diagnostics: Dry contact alarm outputs (NC/NO) for global fault, power pack failure, and output undervoltage

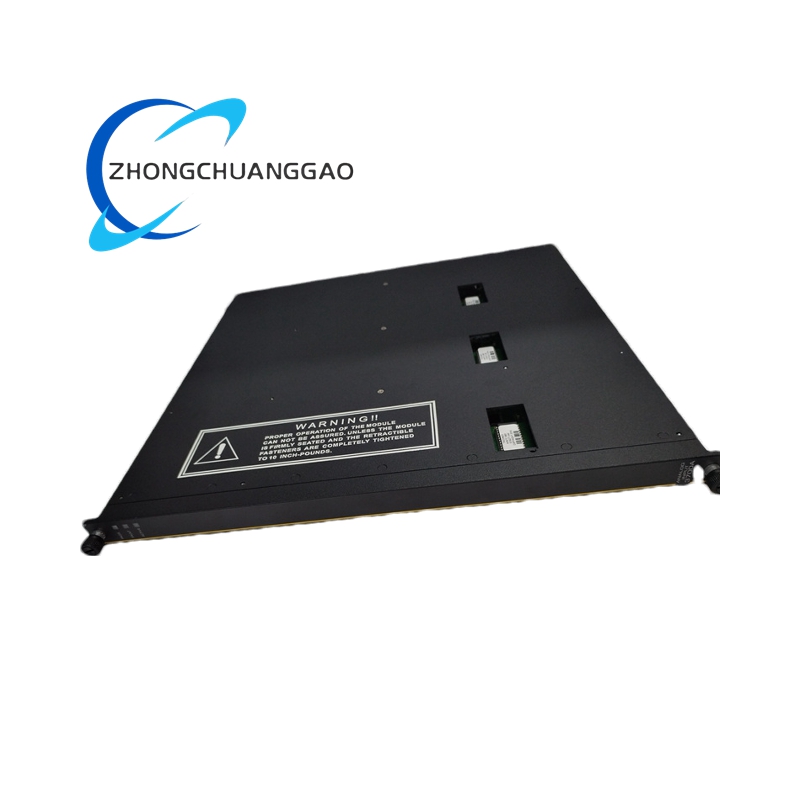

ICS Triplex T8235 Trusted Power Shield

Technical Specifications

-

Mechanical Specifications

- Form Factor: Single‑slot cover for T8240 Power Shelf (matches T8231C Power Pack slot dimensions)

- Mounting: Installs in any unused single‑slot bay of T8240 Power Shelf

- Dimensions (H×W×D): 31 mm × 266 mm × 303 mm (1.22 in × 10.47 in × 11.93 in)

- Weight: 0.5 kg (1.1 lb)

- Material: High‑durability, non‑conductive industrial plastic (UL 94 V‑0 flame‑retardant rating)

- Color: Industrial grey (matches T8240 shelf and T8231C module aesthetics)

- Front Panel: Solid faceplate with integrated snap‑in locking mechanism

- Connection: No electrical connections; passive mechanical fit only

-

Environmental Specifications

- Operating Temperature: -40°C to +70°C (matches T8240 shelf operating range)

- Storage Temperature: -40°C to +85°C

- Relative Humidity: 5%–95% (non‑condensing)

- Shock Resistance: 30 g, 11 ms duration (per IEC 60068‑2‑27)

- Vibration Resistance: 5 g, 10–150 Hz (per IEC 60068‑2‑6)

- Protection Rating: IP20 front panel (prevents finger contact with live parts; protects against solid objects >12 mm)

- EMI/EMC Compliance: Maintains shelf shielding integrity per EN 61000‑6‑2/4

ICS Triplex T8231C Trusted Power Pack

Technical Specifications

-

Electrical Specifications

- Input Voltage: Universal AC 85–264 VAC (47–63 Hz); also supports DC 110/240 VDC (optional)

- Input Frequency: 47–63 Hz (active PFC, power factor ≥ 0.95 at full load)

- Output Voltage: 24 VDC regulated (±0.5% tolerance); adjustable 28 VDC for field devices (optional)

- Output Power: 750 W continuous (100% duty cycle); peak power 900 W for 10 seconds

- Output Ripple: ≤ 50 mVpp (at full load)

- Isolation: 1500 VDC between input and output; 500 VDC between output channels

- Efficiency: ≥ 88% (at 50%–100% load)

- Protection Features: Overvoltage (27 VDC threshold), overcurrent (31 A trip), overtemperature (85°C shutdown), short‑circuit (current‑limited, auto‑recover), reverse polarity (input side)

-

Mechanical Specifications

- Form Factor: 19‑inch rack‑mount power shelf; 1U (43 mm) height

- Dimensions (H×W×D): 43 mm × 483 mm × 340 mm (1.71 in × 19 in × 13.36 in)

- Weight: 2.7 kg (5.95 lbs)

- Mounting: 19‑inch EIA‑310 rack (flange‑mount brackets included)

- Indicators: Front‑panel LEDs for AC input OK, DC output OK, module fault, overtemperature, and redundancy status

- Connectors: IEC 60320 C14 AC input; terminal block for 24 VDC output (screw‑locked, 6‑pole)

- Hot‑Swap: Yes (supports 1+1 redundant hot‑swap with automatic load sharing)

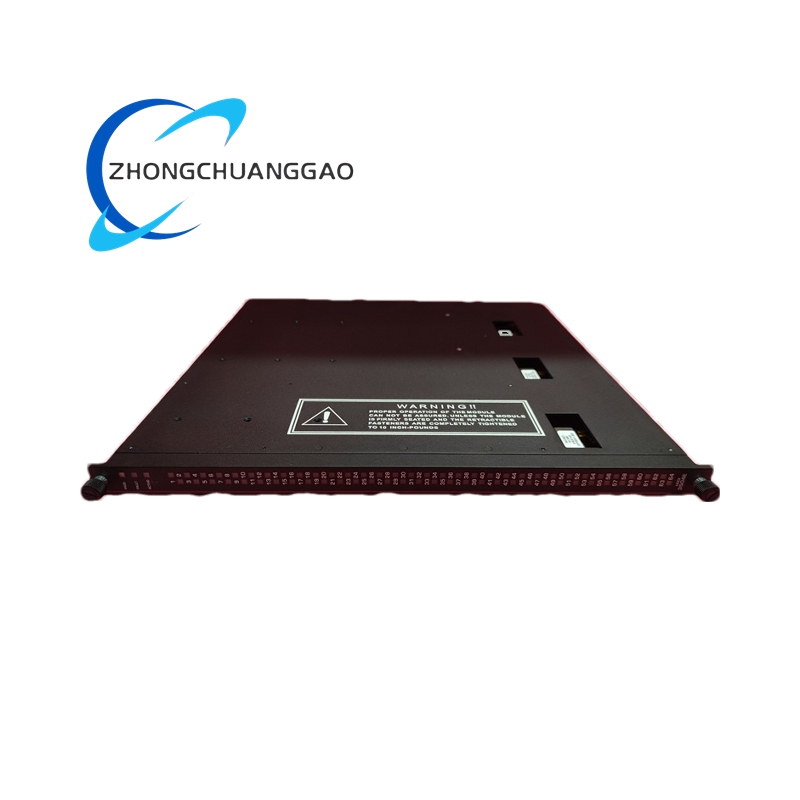

ICS Triplex T8193 Trusted Three‑Slot Wide Empty Cover Module

ICS Triplex T8193 Product Information (Manufactured by ICS Triplex, a Rockwell Automation Brand)

The T8193 is a Trusted Three‑Slot Wide Empty Cover Module—a passive mechanical filler designed exclusively for T8100 controller/expander chassis, providing environmental protection for unused three‑slot bays, maintaining chassis airflow integrity, and supporting hot‑swap compatibility while preserving the system’s IEC 61508 SIL 3 safety certification for TMR architectures.

Product Name

ICS Triplex T8193 Trusted Three‑Slot Wide Empty Cover Module (Part Number: T8193; Form Factor: Three‑Slot Wide 3U Eurocard; Compatible Chassis: T8100 Controller/Expander Chassis; Category: Passive Mechanical Filler Module; No Electrical Components)

Product Overview

The ICS Triplex T8193 is a purpose‑built, passive three‑slot wide empty cover module for Trusted T8100‑series TMR systems. It installs in unused three‑slot bays of T8100 chassis to seal empty slots, preventing dust, moisture, and physical debris from entering the chassis interior while maintaining proper internal airflow for heat dissipation. The module features a robust, high‑impact plastic construction matching the chassis mechanical footprint, with no electrical components or backplane connections. It supports hot‑swap installation and removal without system shutdown, ensuring operational continuity during configuration changes. The T8193 preserves the chassis’s mechanical integrity and electromagnetic shielding, aligning with SIL 3 safety requirements for safety instrumented systems (SIS) in critical industrial environments.

Technical Specifications

-

Mechanical Specifications

- Form Factor: Three‑slot wide 3U Eurocard (matches T8100 chassis slot spacing)

- Mounting: Installs in any unused three‑slot bay of T8100 controller/expander chassis

- Dimensions (H×W×D): 241 mm × 90 mm × 300 mm (9.5 in × 3.5 in × 11.8 in)

- Weight: 0.45 kg (0.99 lbs)

- Material: High‑impact, flame‑retardant industrial plastic (UL 94 V‑0 rated)

- Color: Black (matches T8100 chassis and active module aesthetics)

- Front Panel: Solid faceplate with integrated chassis locking mechanism

- Connection: No electrical backplane connections; passive mechanical fit only

-

Environmental Specifications

- Operating Temperature: -40°C to +70°C (matches T8100 chassis operating range)

- Storage Temperature: -40°C to +85°C

- Relative Humidity: 5%–95% (non‑condensing)

- Shock Resistance: 30 g, 11 ms duration (per IEC 60068‑2‑27)

- Vibration Resistance: 5 g, 10–150 Hz (per IEC 60068‑2‑6)

- Protection Rating: IP40 front panel (protects against solid objects >1 mm and splashing water)

- EMI/EMC Compliance: Maintains chassis shielding integrity per EN 61000‑6‑2/4

ICS Triplex T8153 Trusted Rear‑Mounted Communication Interface Adapter

Technical Specifications

-

Electrical Specifications

- Operating Voltage: 20–32 VDC (24 VDC rated, supplied by T8100 chassis backplane)

- Power Consumption: 5 W (supplemental to T8151C module power)

- Communication Interfaces: 2×10/100BaseT Ethernet (RJ45, auto‑negotiation), 4×RS422/485 (screw terminals, configurable 2‑wire/4‑wire), 1×RS232 (DB9, front‑panel pass‑through for T8151C diagnostics)

- Ethernet Data Rate: 10/100 Mbit/s (auto‑sensing, supports failover)

- Serial Port Baud Rate: 1.2–115.2 kbps (per port configuration via T8151C)

- Signal Isolation: 1500 VDC reinforced isolation between communication circuits and chassis ground (matches T8151C module isolation)

- Power Input Protection: Reverse polarity and overvoltage protection (integrated with chassis backplane)

-

Mechanical Specifications

- Form Factor: Rear‑mounted termination assembly (paired with T8151C single‑width 3U Eurocard)

- Mounting: Direct attachment to T8100 chassis rear rail, aligned with T8151C module slot

- Dimensions (H×W×D): 241 mm × 30 mm × 106 mm (9.5 in × 1.2 in × 4.2 in)

- Weight: 0.42 kg (0.93 lbs)

- Indicators: Front‑panel LEDs for Ethernet link/activity, serial port activity, and module power

- Connector Types: RJ45 (Ethernet), screw terminals (RS422/485), DB9 (RS232 diagnostics)

ICS Triplex T8151C Trusted Communications Interface Module

Technical Specifications

-

Electrical Specifications

- Operating Voltage: 20–32 VDC (rated 24 VDC, supplied by T8100 chassis backplane)

- Power Consumption: 25 W (excludes T8153 adapter power draw)

- Communication Interfaces: 2×10/100BaseT Ethernet (copper, auto‑negotiation), 4×RS422/485 (via T8153 adapter, configurable 2‑wire/4‑wire), 1×RS232 front‑panel diagnostic port

- Ethernet Data Rate: 10/100 Mbit/s (auto‑sensing)

- Serial Port Baud Rate: 1.2–115.2 kbps (configurable per port)

- Processor: Dedicated Motorola PowerPC (communication task offloading)

- Memory: Flash (firmware), RAM (runtime data), EPROM (bootstrap)

- Signal Isolation: Reinforced 1500 VDC isolation between communication circuits and chassis ground

- Power Input Protection: Reverse polarity and overvoltage protection

-

Mechanical Specifications

- Form Factor: 3U Eurocard single‑width module

- Mounting: Installs in any single‑width slot of T8100 controller/expander chassis

- Dimensions (H×W×D): 241 mm × 30 mm × 300 mm (9.5 in × 1.2 in × 11.8 in)

- Weight: 0.92 kg (2.03 lbs)

- Indicators: Front‑panel LEDs for power, Ethernet link/activity, serial port activity, module fault, and system status

- Companion Hardware: Requires T8153 rear‑mounted adapter for external serial/Ethernet connections

ICS Triplex T8151C Trusted Communications Interface Module

Technical Specifications

-

Electrical Specifications

- Operating Voltage: 20–32 VDC (rated 24 VDC, supplied by T8100 chassis backplane)

- Power Consumption: 25 W (excludes T8153 adapter power draw)

- Communication Interfaces: 2×10/100BaseT Ethernet (copper, auto‑sensing), 4×RS422/485 (via T8153 adapter, configurable 2‑wire/4‑wire), 1×RS232 front‑panel diagnostic port

- Ethernet Data Rate: 10/100 Mbit/s (auto‑negotiation)

- Serial Port Baud Rate: 1.2–115.2 kbps (configurable per port)

- Processor: Dedicated Motorola PowerPC (communication task offloading)

- Memory: Flash (firmware), RAM (runtime data), EPROM (bootstrap)

- Signal Isolation: Reinforced 1500 VDC isolation between communication circuits and chassis ground

- Power Input Protection: Reverse polarity and overvoltage protection

-

Mechanical Specifications

- Form Factor: 3U Eurocard single‑width module

- Mounting: Installs in any single‑width slot of T8100 controller/expander chassis

- Dimensions (H×W×D): 241 mm × 30 mm × 300 mm (9.5 in × 1.2 in × 11.8 in)

- Weight: 0.92 kg (2.03 lbs)

- Indicators: Front‑panel LEDs for power, Ethernet link/activity, serial port activity, module fault, and system status

- Companion Hardware: Requires T8153 rear‑mounted adapter for external serial/Ethernet connections

ICS Triplex T8151B Trusted Communications Interface Module

Technical Specifications

-

Electrical Specifications

- Operating Voltage: 20–32 VDC (rated 24 VDC, supplied by T8100 chassis backplane)

- Power Consumption: 24 W (excludes T8153 adapter power draw)

- Communication Interfaces: 2×10/100BaseT Ethernet (copper), 4×RS422/485 (via T8153), 1×RS232 front‑panel diagnostic port

- Ethernet Data Rate: 10/100 Mbit/s (auto‑sensing)

- Serial Port Baud Rate: 1.2–115.2 kbps (configurable)

- Processor: Motorola PowerPC (dedicated communication processor)

- Memory: Flash memory (firmware), RAM (runtime data), EPROM (bootstrap software)

- Signal Isolation: Reinforced 1500 VDC isolation between communication circuits and chassis ground

-

Mechanical Specifications

- Form Factor: 3U Eurocard single‑width module

- Mounting: Installs in any single‑width slot of T8100 controller/expander chassis

- Dimensions (H×W×D): 241 mm × 30 mm × 300 mm (9.5 in × 1.2 in × 11.8 in)

- Weight: 1.23 kg (2.71 lbs)

- Indicators: Front‑panel LEDs for power, Ethernet link/activity, serial port activity, module fault, and system status

- Companion Adapter: T8151B requires T8153 rear‑mounted adapter for external serial/Ethernet connections

ICS Triplex T8123 Trusted TMR Processor Interface Adapter

Technical Specifications

-

Electrical Specifications

- Operating Voltage: 20–32 VDC (rated 24 VDC, supplied by T8100 chassis backplane)

- Communication Ports: 2 configurable RS422/485 (2‑wire or 4‑wire), 1 fixed RS422/485 (2‑wire)

- Time Synchronization: IRIG‑B002/B122 time code input for precise event correlation

- Signal Isolation: Reinforced 1500 VDC isolation between communication circuits and chassis ground

- Fault/Fail Terminals: Dedicated inputs for active and standby processor fault/fail signals

- PSU Monitoring: Inputs to track T8100 chassis power supply shutdown signals

- Diagnostic Interface: 1 dedicated port for processor configuration and troubleshooting

-

Mechanical Specifications

- Form Factor: Rear‑mounted adapter for T8100 chassis, matching T8000‑series module dimensions

- Mounting: Direct rear‑panel connection; no additional tools required for installation

- Dimensions: 16 cm × 16 cm × 12 cm (typical)

- Weight: Approximately 0.8 kg

- Indicators: Front‑panel LEDs for power status, communication link activity, and fault signal detection

-

Environmental Specifications

- Operating Temperature: -40°C to +70°C

- Storage Temperature: -40°C to +85°C

- Relative Humidity: 5%–95% (non‑condensing)

- Shock Resistance: 30 g, 11 ms duration (per IEC 60068‑2‑27)

- Vibration Resistance: 5 g, 10–150 Hz (per IEC 60068‑2‑6)

ICS Triplex T8122 Trusted Processor Interface Adapter

Technical Specifications

- Electrical Specifications

- Operating Voltage: 20–32 VDC (rated 24 VDC, derived from T8100 chassis backplane)

- Communication Ports: 2 configurable RS422/485 (2 - or 4 - wire), 1 fixed RS422/485 (2 - wire)

- Signal Isolation: Reinforced isolation (1500 VDC) between communication circuits and chassis ground

- Fault/Fail Signal Inputs: Dedicated terminals for active/standby processor fault and fail signals

- PSU Monitoring: Inputs for tracking power supply shutdown signals from the T8100 chassis

- Diagnostic Interface: 1 dedicated port for processor diagnostics and configuration access

- Mechanical Specifications

- Form Factor: Rear - mounted adapter for T8100 chassis, matching T8000 - series module dimensions

- Mounting: Direct connection to the chassis rear panel; no additional tools required for installation

- Dimensions: 9.5 cm × 6.3 cm × 2.1 cm

- Weight: Approximately 0.3 kg

- Indicators: LED indicators for power status, communication link activity, and fault signal detection

- Environmental Specifications

- Operating Temperature: - 40°C to +70°C

- Storage Temperature: - 40°C to +85°C

- Relative Humidity: 5%–95% (non - condensing)

- Shock Resistance: 30 g, 11 ms duration (per IEC 60068 - 2 - 27)

- Vibration Resistance: 5 g, 10–150 Hz (per IEC 60068 - 2 - 6)

ICS Triplex T8111C Trusted Triple – Modular Redundant (TMR) Processor Module

Technical Specifications

- Electrical Specifications

- Operating Voltage: 20–32 VDC (rated 24 VDC)

- Power Consumption: 30 VA (max)

- Memory Capacity: 32 MB RAM, 128 MB flash memory for program and data storage

- Processor Architecture: Hardware - Implemented Fault - Tolerant (HIFT) with triple redundant processing cores

- Communication Interfaces: Front - panel RS232 serial port, Ethernet (TCP/IP), Modbus TCP/IP; supports redundant communication links

- Time Synchronization: IRIG - B002 and B122 time code input for precise event correlation

- Isolation: Reinforced electrical isolation between field circuits, backplane, and module core

- Mechanical Specifications

- Chassis Compatibility: Exclusively designed for T8100 Trusted TMR controller chassis

- Form Factor: Standard T8000 - series module size, 19" rack - mount compatible

- Weight: Approximately 1.9 kg (varies slightly by revision)

- Mounting: Hot - swappable via push - button "education" function; no system shutdown required for replacement

- Indicators: Front - panel LEDs for power status, module health, fault alerts, voting status, and communication link integrity

ICS Triplex T8100 Trusted TMR Controller Chassis

Technical Specifications

- Electrical Specifications

- Operating Voltage: 20–32 VDC (rated 24 VDC)

- External Fusing: 20 A external fuse for power input protection

- Backplane Power: Redundant power distribution to all module slots; 80 W maximum total power dissipation

- Backplane Architecture: Triple redundant Inter - Module Bus (IMB) for TMR communication and voting

- Isolation: Reinforced isolation between field circuits, backplane, and chassis ground

- SOE (Sequence of Events) Buffer: 1000 local events, with a 4000 - event CI (Communication Interface) buffer for post - incident analysis

- Mechanical Specifications

- Form Factor: 19" standard rack - mount chassis, compatible with EIA - 310 - D rack standards

- Module Slots: Supports up to 16 T8000 - series I/O, processor, and communication modules

- Connectors: 10×DIN 41642 male connectors for field and backplane connections

- Indicators: Front - panel LEDs for global power status, backplane health, and module fault alerts; optional front - door window for LED visibility

- Protection Rating: IP20 (front panel); protects against dust and finger contact

- Weight: Approximately 10 kg (varies by configuration)