GE CK11CE300 Industrial Contactor

Technical Specifications

- Rated Current: Suitable for high-power motors and industrial loads, typically up to 600A (specific rating may vary based on configuration).

- Rated Voltage: Supports voltages up to 600V AC, suitable for three-phase power systems.

- Coil Voltage: Multiple options available (AC/DC), depending on the specific model and application requirements.

- Contact Configuration: Commonly available in 3-pole (3P) or 4-pole (4P) configurations for three-phase load control.

GE C6M-9UH-00K UR9CH

Technical Specifications

- Processor: Likely features a high-speed processor (e.g., ARM Cortex or equivalent) for rapid data handling.

- Memory: Supports configurable RAM and Flash storage for program and data retention.

- I/O Points: Includes multiple digital and analog I/O channels for sensor and actuator integration.

- Communication: Equipped with Ethernet, serial ports (RS-232/RS-485), and possibly fieldbus protocols (e.g., Modbus, PROFIBUS).

- Operating Temperature: Designed to withstand industrial temperature ranges (e.g., -20°C to 70°C).

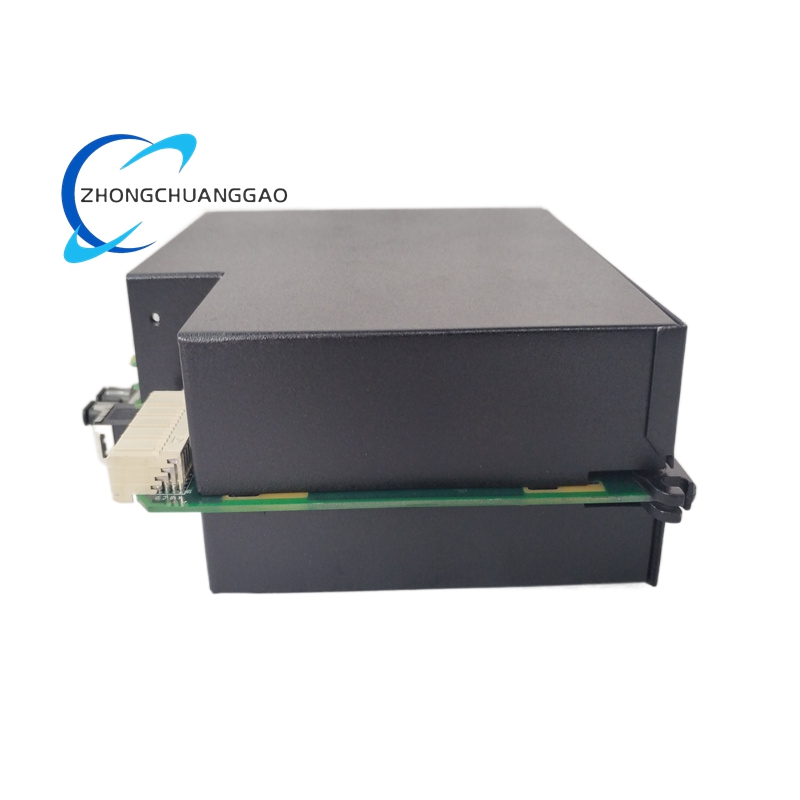

GE BRICK-4-HI-S-CV50-S-X-X

Technical Specifications

- Processor: Likely features a high-speed processor (e.g., ARM Cortex or equivalent) for rapid data handling.

- Memory: Supports configurable RAM and Flash storage for program and data retention.

- I/O Points: Includes multiple digital and analog I/O channels for sensor and actuator integration.

- Communication: Equipped with Ethernet, serial ports (RS-232/RS-485), and possibly fieldbus protocols (e.g., Modbus, PROFIBUS).

- Operating Temperature: Designed to withstand industrial temperature ranges (e.g., -20°C to 70°C).

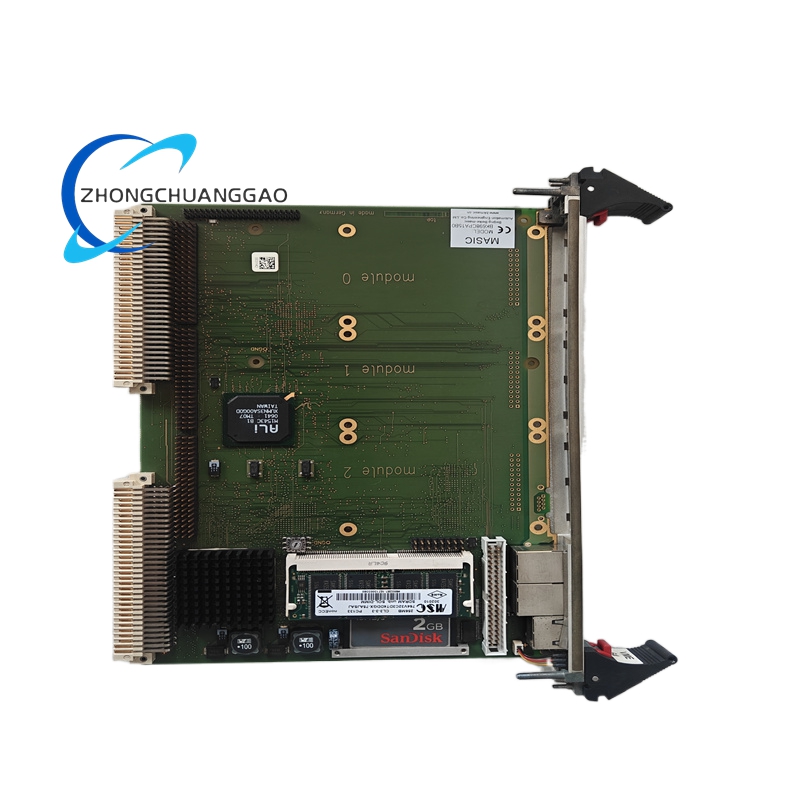

GE BK698CPA15B0 Control Module

Technical Specifications

- Processor: Up to 1.26 GHz Intel Pentium III processor with 256 KB L2 cache (512 KB for 1.26 GHz variant).

- Memory: Supports up to 512 MB PC133 SDRAM via a single SODIMM slot.

- Display: Built-in AGP SVGA controller with 4 MB display cache.

- Networking: Dual Ethernet controllers supporting 10BaseT and 100BaseTX.

- Storage Expansion: Optional PCI dual-channel Ultra160 SCSI functionality.

- Bus Standard: Compliant with VME64 (VersaModule Eurocard) bus architecture, ensuring high bandwidth and performance.

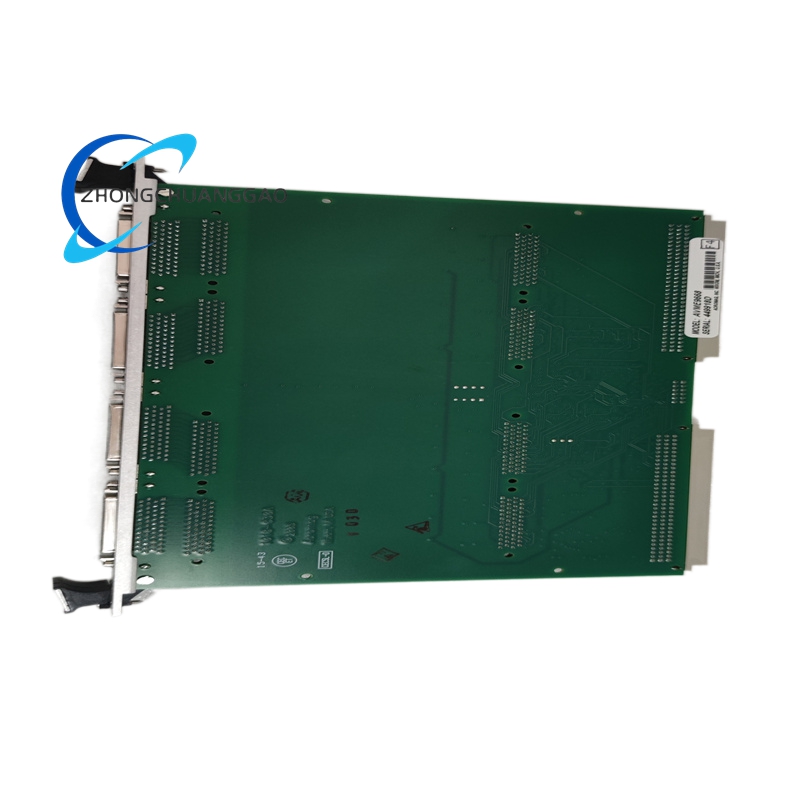

GE AVME-9668 Controller Module

Technical Specifications

- Processor: 32-bit RISC processor or Intel Core i7-7820HQ

- Memory: 256 KB RAM (configurable up to 16 GB DDR4)

- Storage: 2 MB Flash (expandable to 512 GB SSD)

- Graphics: Intel Iris Pro Graphics 580 (specific configurations)

- Communication Interfaces:

- Ethernet (RJ45)

- RS-232/RS-485 serial ports

- Fieldbus support

- I/O Points: Up to 64 digital I/O and 32 analog I/O

GE AO3481

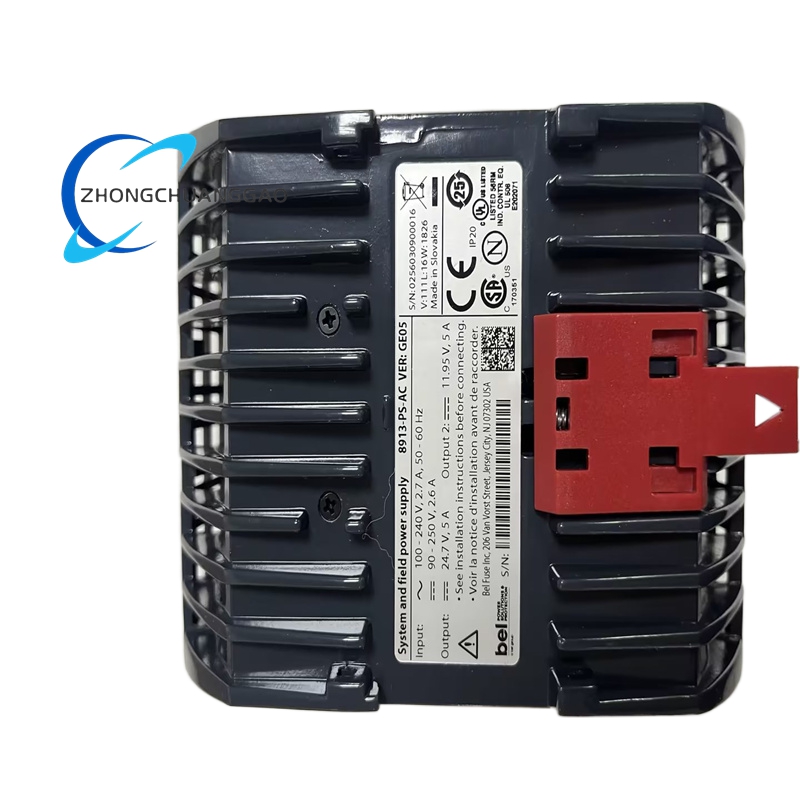

GE 8913-PS-AC Industrial Power Supply Module

Technical Specifications

- Input Voltage Range: 85–264 VAC (supports worldwide grid standards)

- Output Voltage: Dual DC outputs: 5A at 24V DC and 5A at 12V DC

- Efficiency: Optimized circuit design for ≥90% power conversion efficiency

- Operating Temperature: -40°C to +70°C (extreme temperature tolerance)

- Storage Temperature: -40°C to +85°C

- Relative Humidity: 5%–95% RH (non-condensing)

- Isolation Voltage: 1,500V DC input-to-output isolation

- Protection Features: Overcurrent, overvoltage, short-circuit, and reverse-polarity protection

- Dimensions: Compact design for space-saving integration

- Weight: 2.6 kg

GE 8910-PS-DC Industrial DC Power Supply Module

Technical Specifications

- Input Voltage Range: 18.5V–36V DC (wide input range for flexibility)

- Output Voltage: 12V DC (±5% tolerance)

- Output Current: 4.9A (continuous output)

- Power Efficiency: ≥90% (high efficiency reduces energy consumption)

- Operating Temperature: -40°C to +70°C (supports extreme temperature conditions)

- Storage Temperature: -40°C to +85°C

- Relative Humidity: 5%–95% RH (non-condensing)

- Isolation Voltage: Input-to-output: 50V AC RMS / 720V DC (continuous operation under EN 61010-1)

GE 8507-BI-DP Programmable Controller Bus Interface Module (BIM)

Technical Specifications:

- Communication Protocol: PROFIBUS-DP

- Network Bitrate: 9600 bps to 12 Mbit/s

- Power Supply: 24V DC

- Operating Temperature: -20°C to 60°C (extended range: -40°C to 85°C for storage)

- Humidity: 5% to 95% (non-condensing)

- Dimensions: Approximately 140 mm × 60 mm × 25.4 mm

- Weight: Around 200 grams

- Input/Output: Supports multiple digital and analog input/output channels (specific configuration may vary based on model and application requirements)

GE 04220FL11232A RXI Controller

Technical Specifications:

- Processor: High-performance dual-core CPU

- Memory: 4GB RAM, 32GB industrial-grade solid-state drive (expandable to 250GB)

- Power Supply: 24V DC / 48V DC (optional), ≤25W power consumption

- Communication Interfaces:

- Ethernet: Gigabit PROFINET (with built-in MRP redundancy), standard Ethernet ports

- Serial: RS-232 (RJ-45), RS-485

- Wireless: Optional WLAN via internal Mini PCIe card slot

- Fieldbus: Modbus RTU, Profibus (optional)

GE 760-P5-G5-S5-HI-A20-R Feeder Management Relay

GE 705-1512-01 Control Module

Technical Specifications:

- Processor: 32-bit RISC processor

- Memory: 256 KB

- I/O Configuration: 32 digital I/O points, 16 analog I/O points

- Communication Interfaces: RS-232, RS-485, Ethernet

- Display: LCD screen for local parameter viewing and operation

- Protection Class: IP65

- Dimensions: 115 mm × 70 mm × 35 mm (4.5 inches × 2.8 inches × 1.4 inches)