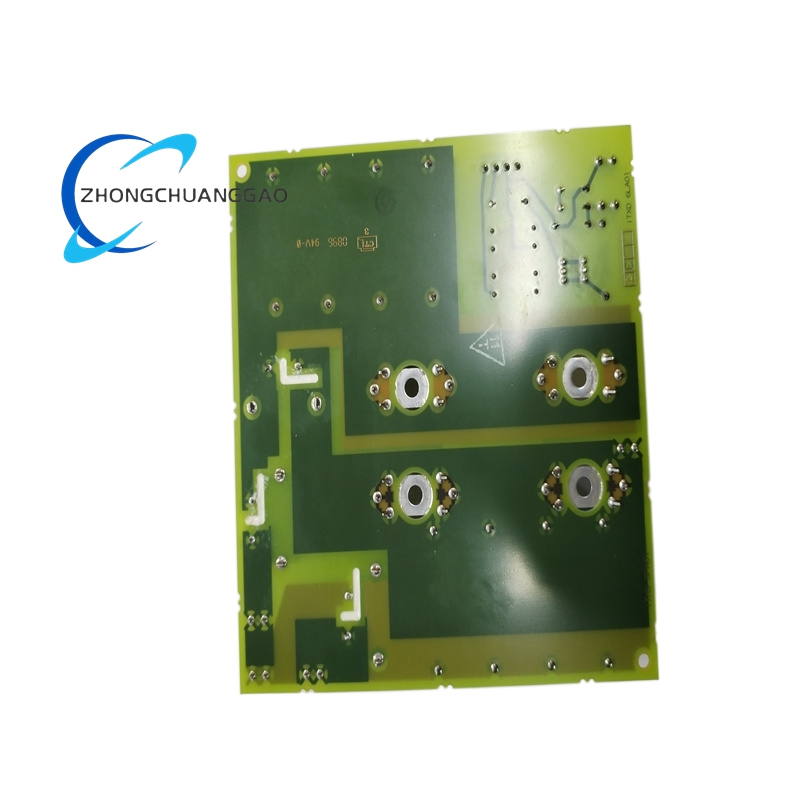

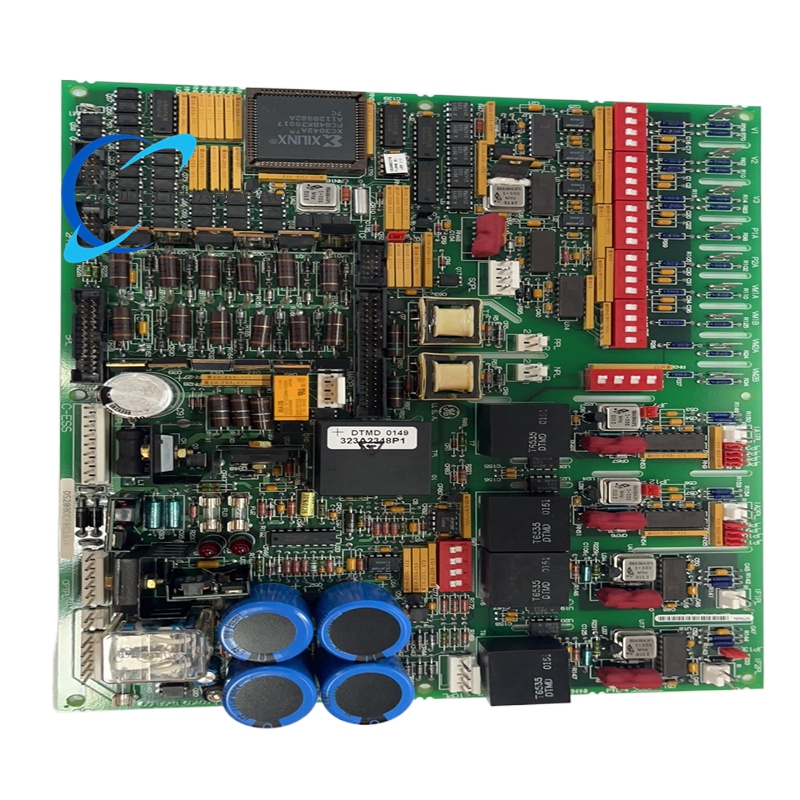

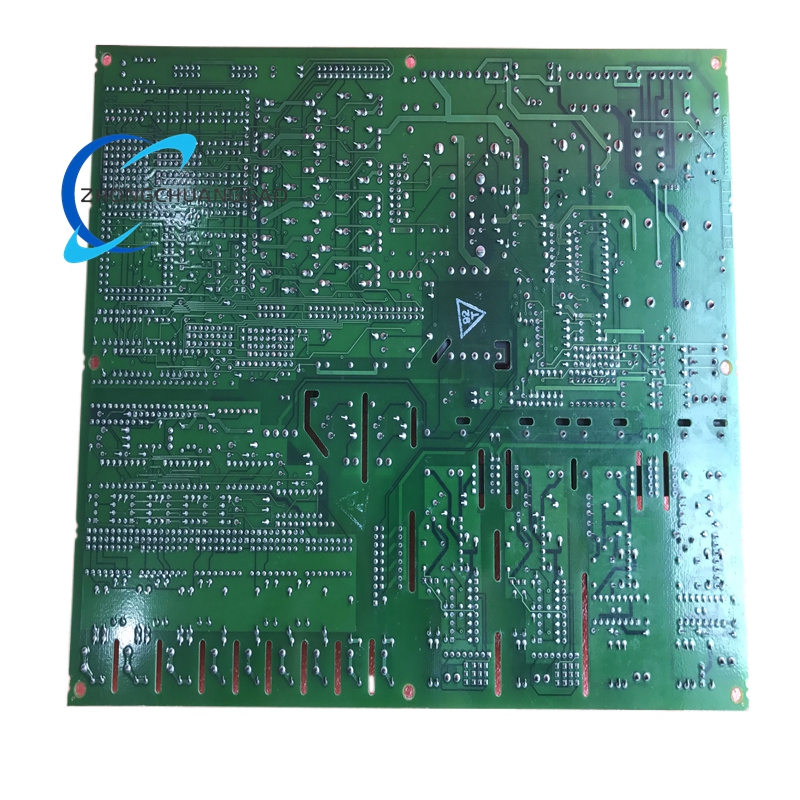

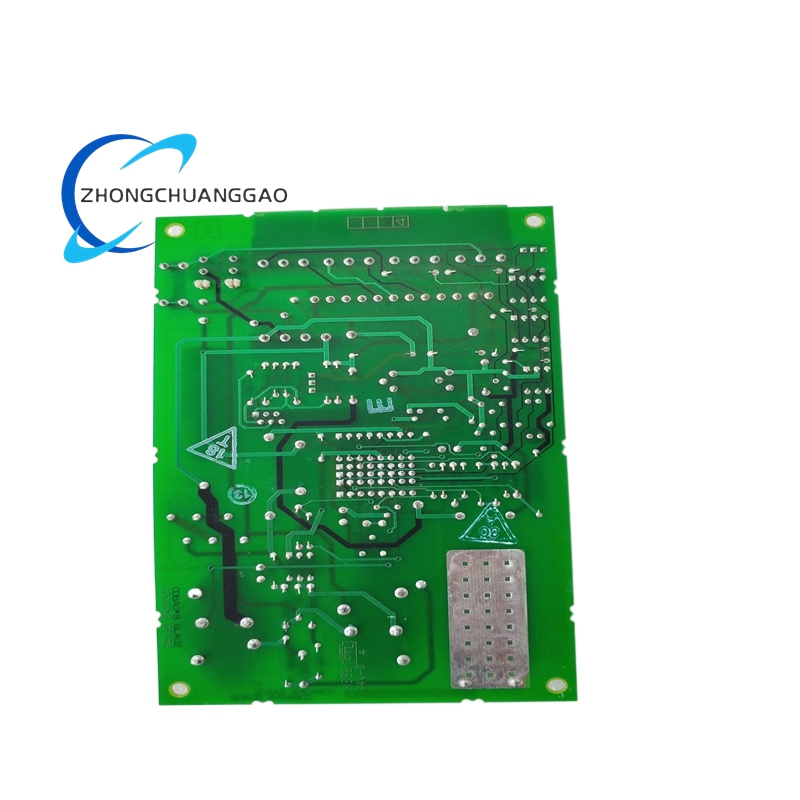

GE DS200ITXDG1ABA Dynamic Braking Buffer Board

Technical Specifications

Board Type: Dynamic braking buffer board

Input Voltage: 375 HP for constant torque applications (575 VAC), 300 HP for variable torque applications (380 VAC)

Connectors: Four-pin connector for interface with the IMCP (Interface Module Control Panel)

IGBT Compatibility: Designed to meet the switching frequency requirements of dynamic braking IGBTs

Output Regulation: Adjusts IGBT gate driver outputs to match the electrical characteristics of AT frame drivers

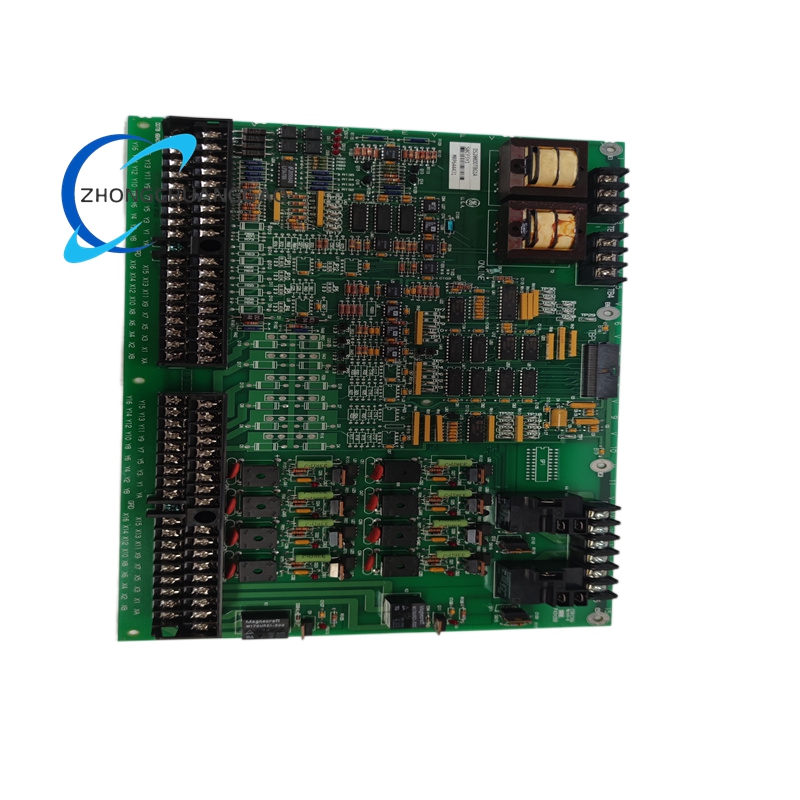

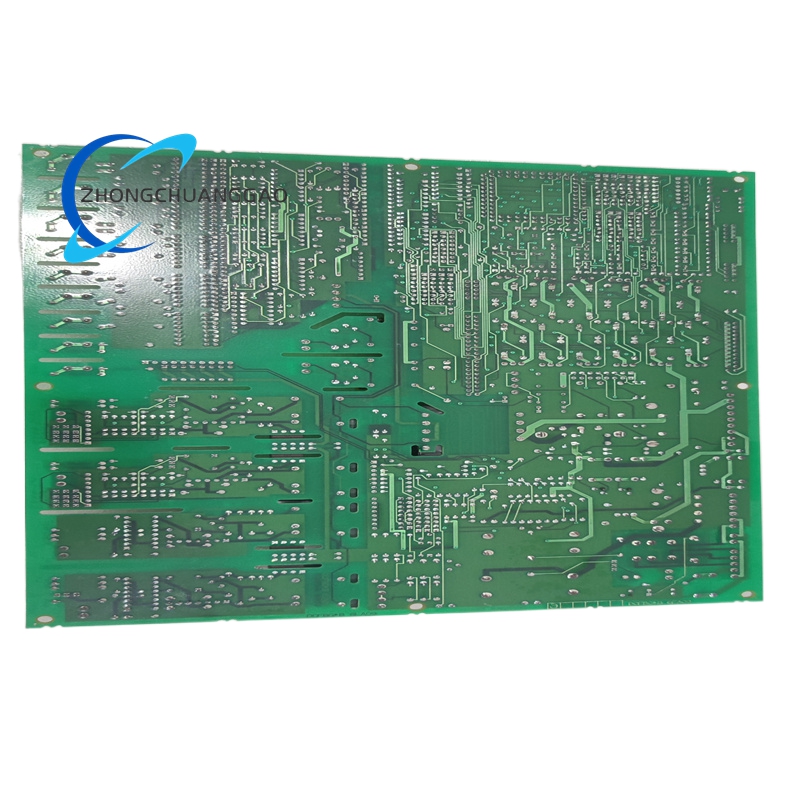

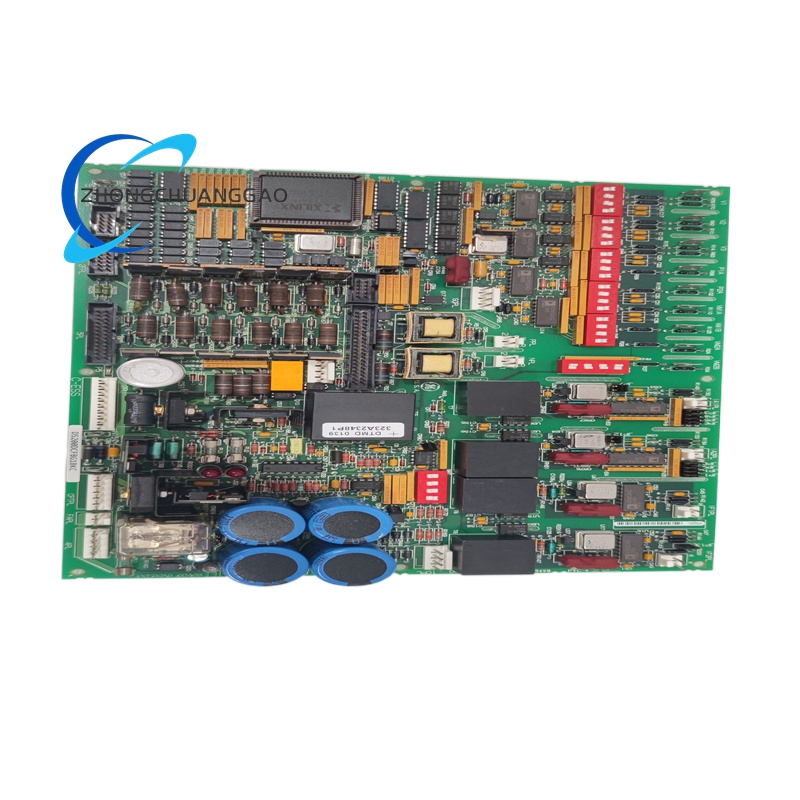

GE DS200DDTBG1A LCI Auxiliary I/O Terminal Board

Technical Specifications

- Input Voltage: 24 V DC

- Outputs: Four buffered analog outputs (±10 V range with 200 Ω series resistors)

- LED Indicators: 17 LEDs (1 for board status, 16 driven by software/hardware for diagnostic feedback)

- Jumpers: 12 jumpers for reconfiguring LEM/CT input channels to 4-20 mA current loop signals

- Test Points: 33 test points for signal measurement and debugging

- Connectivity: Screw-type terminal blocks for secure wiring connections

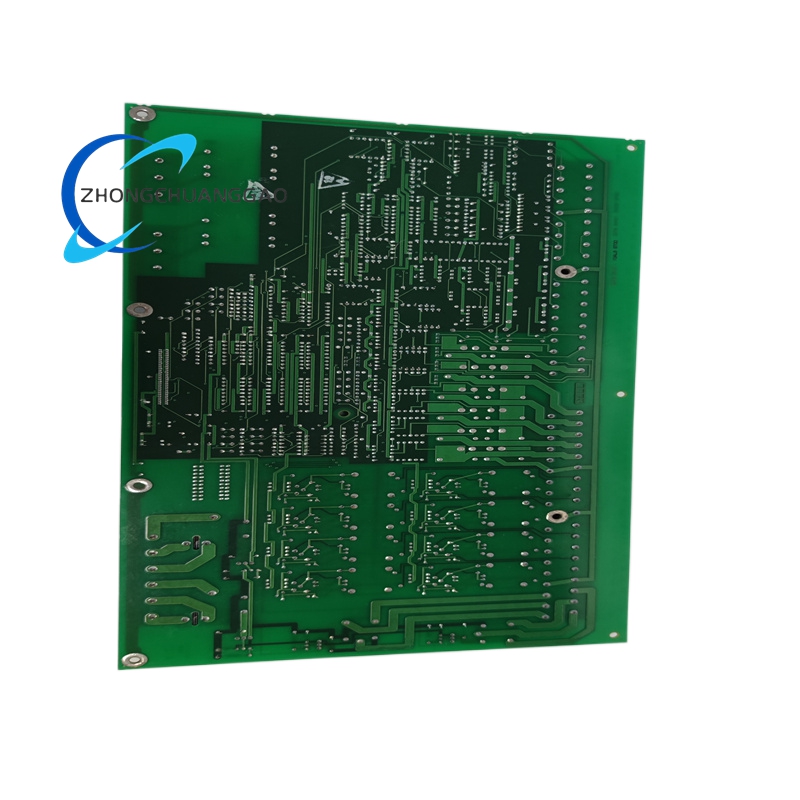

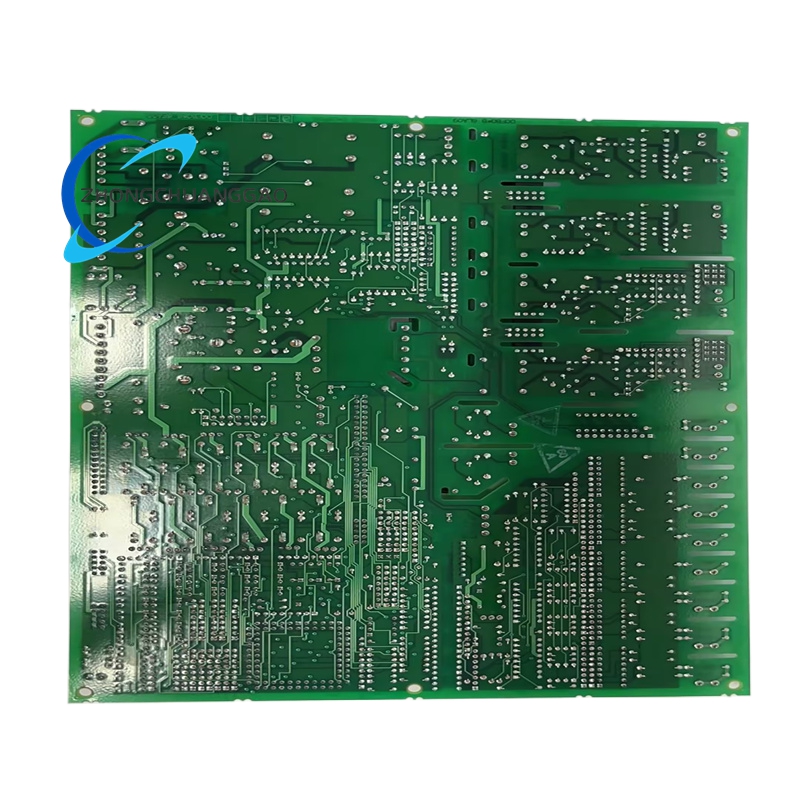

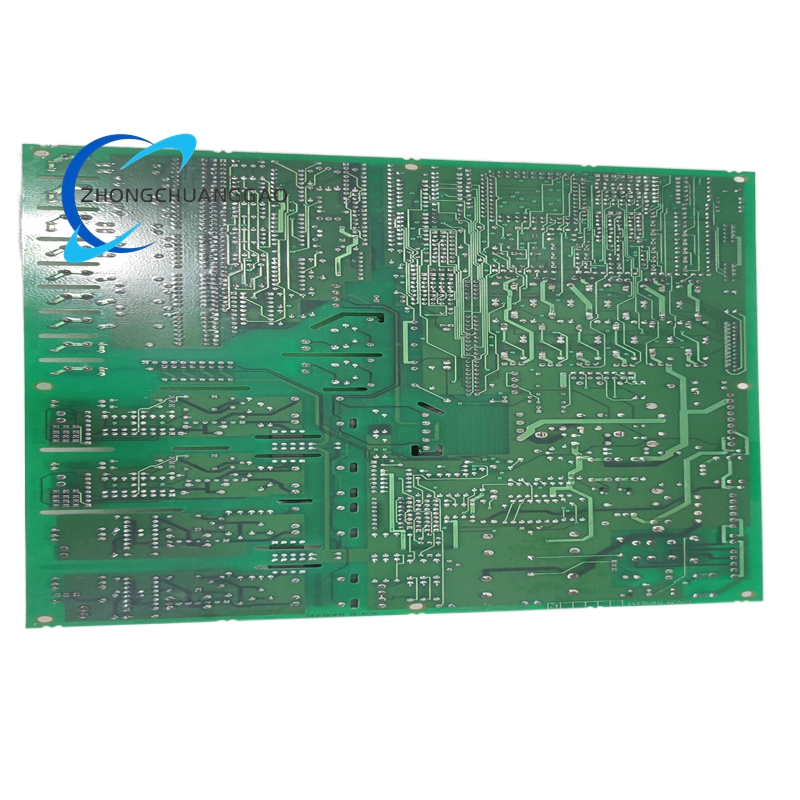

GE DS200DCFBG1BLC DC Feedback Power Supply Board

Technical Specifications

- Input Voltage: 38–115 VAC, 47–63 Hz (supports dual redundant inputs for enhanced reliability).

- Output Voltages:

- +5 V DC (4 A)

- ±15 V DC (0.8 A each)

- ±24 V DC (3 A/1 A)

- VCO Output: 0–500 kHz (nominal 250 kHz), isolated at 2.5 kV logic-to-power and 500 V channel-to-chassis.

- Feedback Input: Electromotive and field shunt resistors (50 mV–250 mV range).

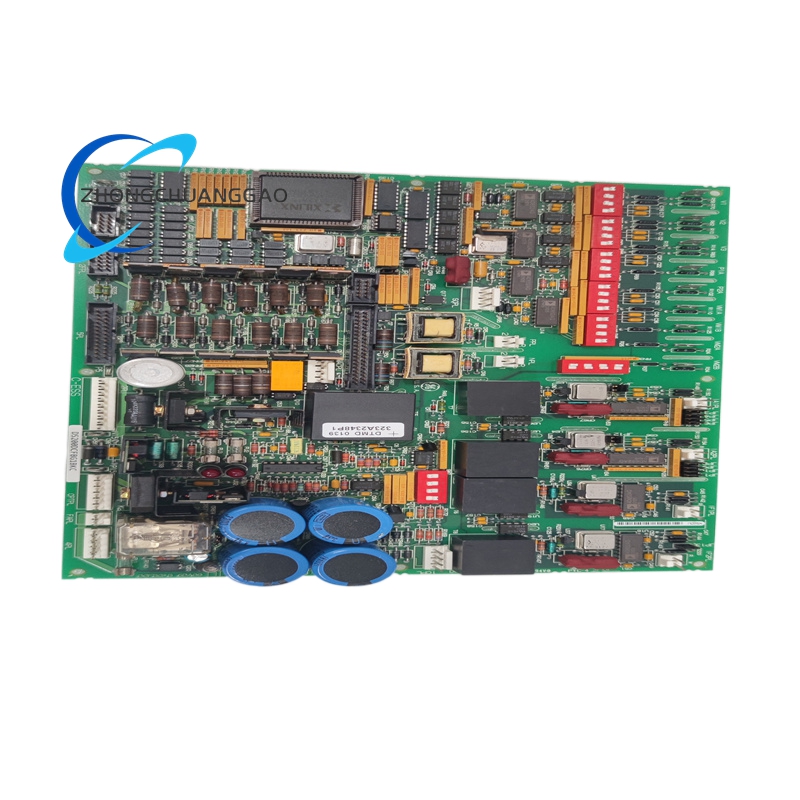

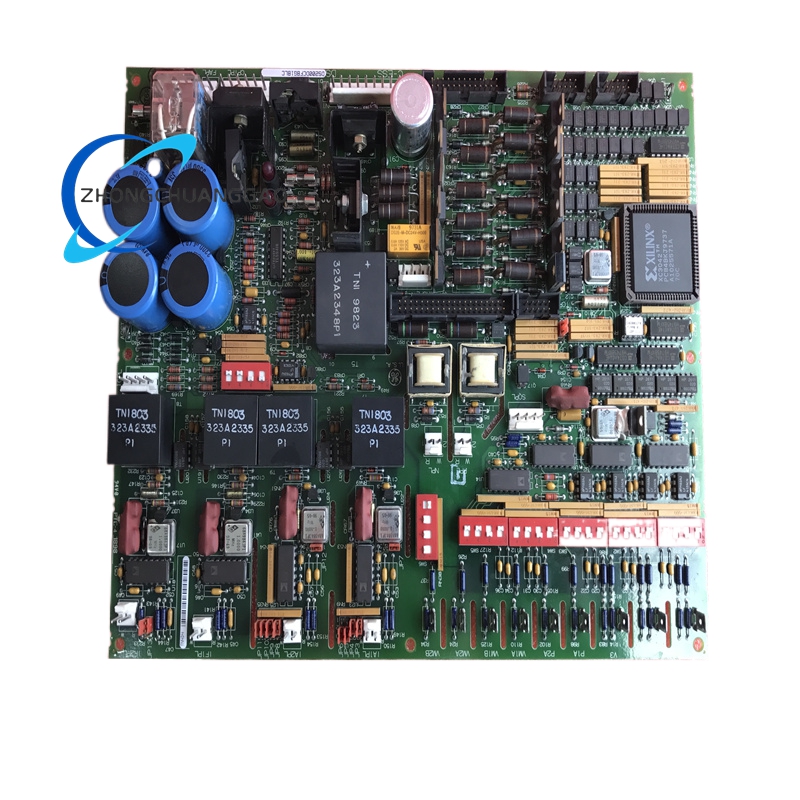

GE DS200DCFBG1BJB Drive Control Power Supply Board

Technical Specifications

- Input Voltage Range: Compatible with multiple industrial power sources, typically ranging from 38 to 115 VAC (depending on system requirements).

- Output DC Voltage: Adjustable to meet the specific needs of connected drivers or exciters.

- Fan Power Supply: 115V AC (independent circuit to ensure reliable cooling).

- Protection Features:

- Overcurrent protection to prevent equipment damage.

- Overvoltage/undervoltage protection to ensure system stability.

- Feedback signal isolation to absorb millivolt-level interference and avoid unintended motor starts.

GE DS200DCFBG1BGB DC Feedback Power Supply Board

Technical Specifications

- Input Voltage Range: Compatible with multiple industrial power sources, typically ranging from 38 to 115 VAC (depending on system requirements).

- Output DC Voltage: Adjustable to meet the specific needs of connected drivers or exciters.

- Fan Power Supply: 115V AC (independent circuit to ensure reliable cooling).

- Efficiency: High conversion efficiency to minimize energy loss.

- Protection Features:

- Overcurrent protection to prevent equipment damage.

- Overvoltage/undervoltage protection to ensure system stability.

- Feedback signal isolation to absorb millivolt-level interference and avoid unintended motor starts.

GE DS200DCFBG1B DC Feedback Power Supply Board

Technical Specifications

- Input Voltage Range: Compatible with various industrial power sources (specific range depends on system requirements).

- Output DC Voltage: Adjustable (customizable based on drive requirements).

- Fan Power Supply: 115V AC (independent circuit for reliable cooling).

- Protection Features:

- Overcurrent protection: Automatically cuts off abnormal currents to prevent damage.

- Overvoltage/undervoltage protection: Monitors voltage fluctuations to ensure system stability.

- Feedback signal isolation: Absorbs millivolt-level interference to prevent unintended motor starts.

GE DS200CPCAG1ABB Contactor Guide Plate

Technical Specifications

Connectors:

One 12-pin connector

Two 2-pin connectors

Terminal Blocks: Four terminal blocks, supporting up to twelve signal wire connections.

Power Relay: Integrated 24VDC 15A socket power relay for reliable power distribution.

Electrical Ratings:

Rated Current: 16A

Rated Voltage: AC 240V

GE DS200CDBAG1ABA Mark V Turbine Control System Contactor Driver Board

Technical Specifications

- Function: Contactor driver for Mark V turbine control systems.

- Components: Includes a jumper (JP1) for factory testing, an electrometer for adjusting the current applied to contactor coils, and test points for board operation verification.

- Connectors: Connector 1TB consists of four parts (1TBA, 1TBB, 1TBC, 1TBD) for secure electrical connections.

- Protection: Features a 4 amp, 125 V, 2AG slow-blow fuse for overcurrent protection.

- Coating: The PCB is coated with a protective layer to shield against daily wear and tear and provide insulation.

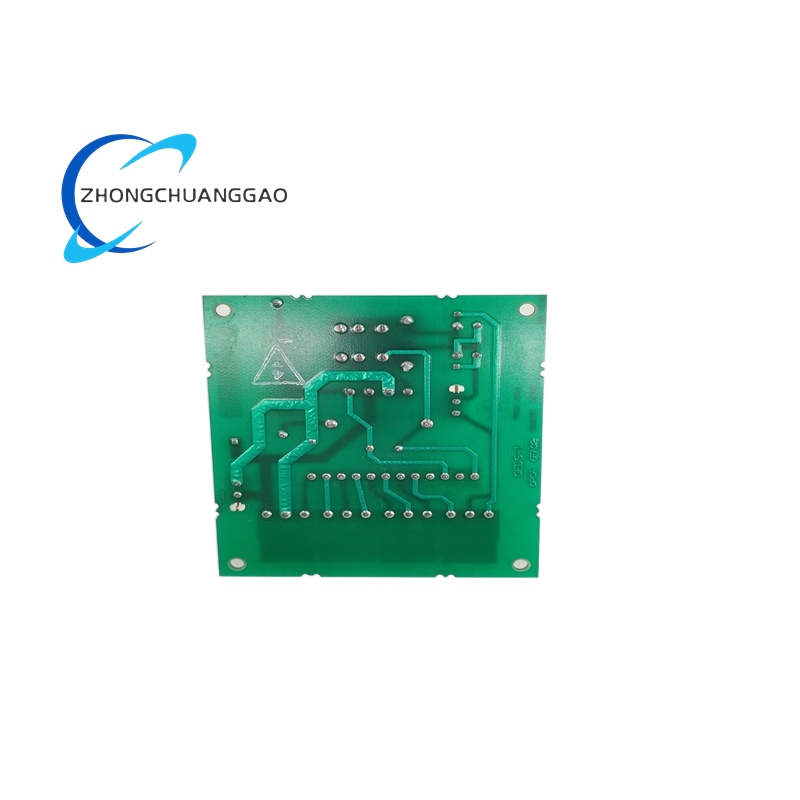

GE D1063S Load Cell Signal Repeater and Isolator

Technical Specifications

- Input: Accepts signals from load cells in hazardous areas (Zone 0, Zone 20, Division 1).

- Output: Repeats the mV signal output to drive a load in the safe area, depending on the host system reference voltage.

- Load Cell Connection: Supports up to four 350 Ω load cells, six 450 Ω load cells, or twelve 1000 Ω load cells connected in parallel.

- Voltage Reference: Configurable via DIP switch to select internal or external (host system) supply.

- Isolation: Three-port isolation (Input/Output/Supply) for enhanced safety and signal integrity.

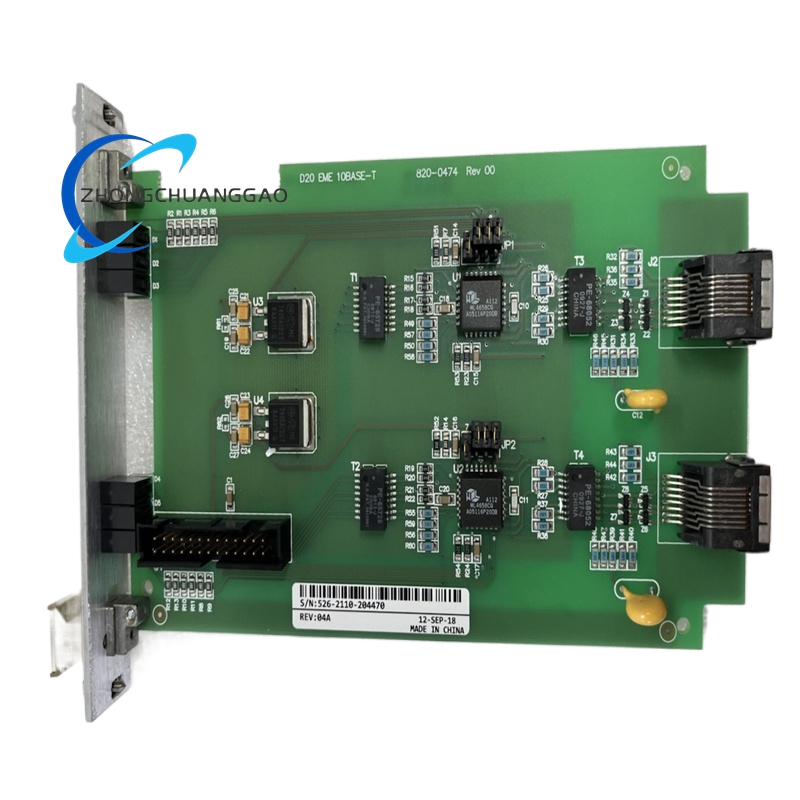

GE D20 EME 10BASE-T Digital Control Module

Technical Specifications

- Communication Interface: 10BASE-T Ethernet, supporting data transmission rates of up to 10 Mbps.

- Power Requirements: Input voltage range of 85-265 VAC, 50/60 Hz, with an output voltage of 24 VDC and a maximum current load of 2 A.

- Operating Temperature: -20°C to +70°C, ensuring stable performance in harsh industrial conditions.

- Physical Specifications: Aluminum alloy housing with dimensions of 100 mm x 100 mm x 50 mm and a weight of 500 g.

GE CR224 Integrated Circuit (IC)

Technical Specifications

- Type: Integrated Circuit (IC)

- Functionality: High-frequency operation

- Available Models: Various models with different specifications, including but not limited to, CD40110BE, L6599ADTR, PK90FG160, MTT46A09F, MBRS340T3, DF75LA160, etc.

- Package Types: SOP-16, HTSSOP(DAD)-32, SOT23-6, etc.

- Voltage Ratings: Specific voltage ratings vary by model, catering to different power requirements.

- Current Ratings: Designed to handle different current levels based on the application needs.

- Frequency Range: High-frequency operation suitable for demanding electronic circuits.

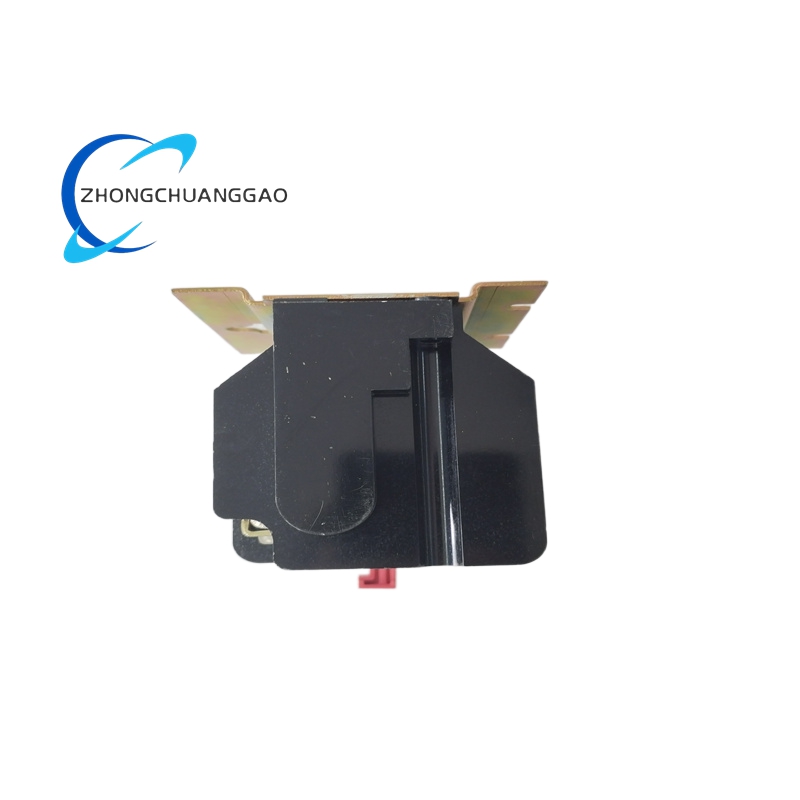

GE CK12BE300 AC Contactor

Technical Specifications

- Rated Voltage:

- AC: Up to 690V

- DC: Up to 550V

- Rated Current: Varies by model (e.g., CK12BE311N has a rated current of 220V2).

- Contact System:

- Three sets of main contacts for high-current applications.

- One set of auxiliary contacts for additional control functions.

- Electromagnetic System: Utilizes electronic modules compatible with both AC and DC power supplies.