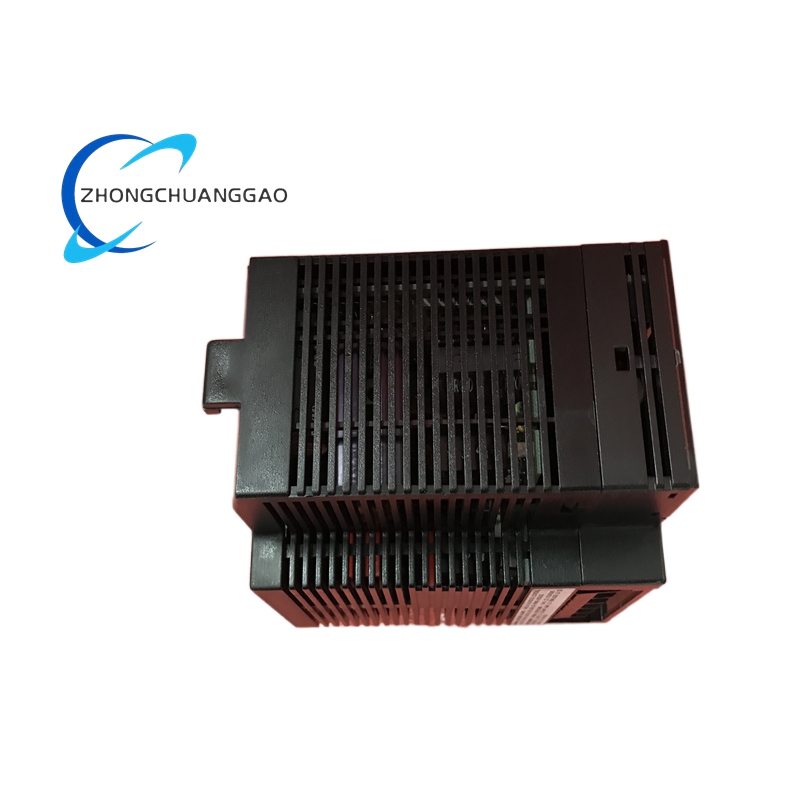

GE IC693PWR330

Product Overview

The IC693PWR330 is a single‑slot, high‑capacity power supply module from GE Fanuc (Emerson Automation) for Series 90‑30 PLC systems, designed to deliver 30W total output with flexible power distribution—all 30W can be allocated to the +5VDC output for high‑current logic loads, while also providing +24VDC Relay (for output modules) and isolated +24VDC (for field devices). It accepts 85–264 VAC (50/60 Hz) or 100–300 VDC input, with 1500VAC isolation between outputs and input, over‑current/over‑voltage protection, and 4A peak inrush current tolerance (250 ms max). The module fits the leftmost slot of Series 90‑30 baseplates, delivering 6A max +5VDC, 0.625A max +24VDC Relay, and 0.833A max isolated +24VDC, with LED indicators for power and output status, ensuring stable backplane power for large CPU/module configurations in industrial automation.

GE IC693PWR322F

Product Overview

The IC693PWR322F is a single‑slot DC‑input power supply module from GE Fanuc (Emerson Automation) for Series 90‑30 PLC systems, delivering +5VDC (logic), +24VDC Relay (output modules), and +24VDC Isolated (field devices) with 30W total output and 50W input power. It operates from 18–56VDC (21VDC minimum start), providing 1500VAC isolation between outputs and input, with over‑current/over‑voltage protection and LED status indicators. It fits standard Series 90‑30 baseplates, supporting CPU logic, I/O modules, and field loads in industrial automation with no internal battery backup.

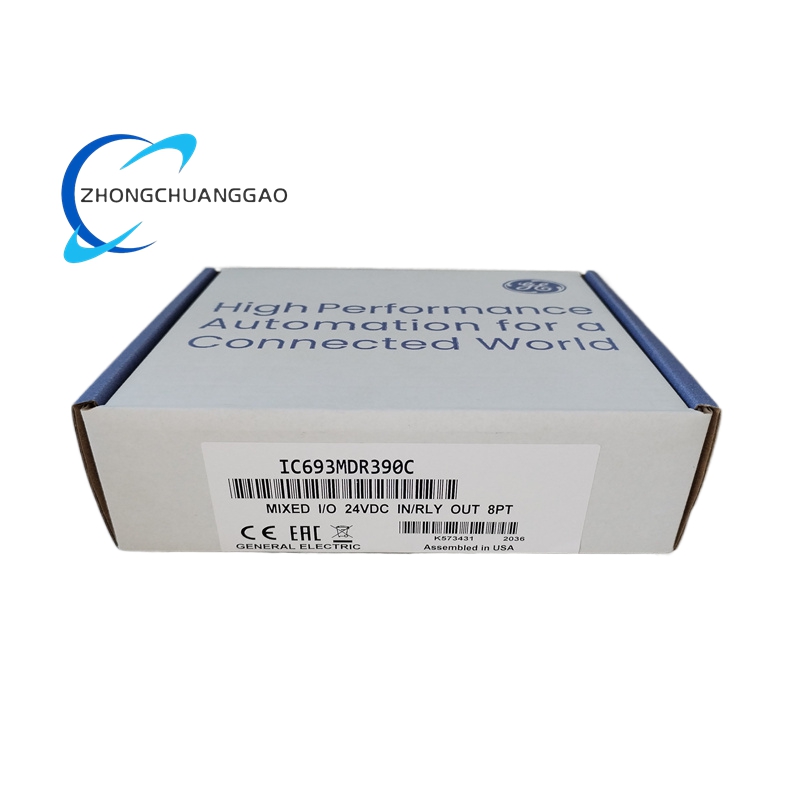

GE IC693MDR390C

Product Overview

The IC693MDR390C is a single‑slot mixed I/O module from GE Fanuc (Emerson Automation) for the Series 90‑30 PLC platform, integrating 8 channels of 24VDC discrete input (sinking/sourcing) and 8 channels of normally‑open relay output (2 groups × 4 channels, independent commons). It features 1500VAC field‑to‑logic optical isolation and 500VAC group‑to‑group isolation to block noise and transients, supporting 15–32VDC input voltage and 5–30VDC/5–250VAC output voltage. The module delivers 2A max per output channel and 4A max per group common, with 70 mA 24V relay supply and 80 mA 5V backplane power draw. It offers 7 ms typical input response and ≤15 ms output response, with channel‑level LEDs for input/output status, serving as a compact, integrated interface for combined sensing and actuation in industrial automation.

GE IC693MDL940H

Product Overview

The IC693MDL940H is a single‑slot 16‑channel relay output module from GE Fanuc (now Emerson Automation) for the Series 90‑30 PLC platform, configured as 4 groups of 4 channels with independent commons. It provides 1500VAC field‑to‑logic and 500V group‑to‑group isolation, handling 5–30VDC/5–250VAC loads at 2A per channel. The module draws 7 mA from the 5V backplane and 135 mA from the 24V backplane (all outputs ON), with green LEDs per channel for output status. It integrates with all Series 90‑30 CPUs, baseplates, and power supplies, serving as a robust, isolated interface for industrial motor starters, solenoids, and indicators.

GE IC693MDL753K

Product Overview

The IC693MDL753K is a 32‑channel discrete output module from GE Fanuc (now part of Emerson Automation) for the Series 90‑30 PLC platform, offering 0.5A per‑channel transistor outputs in four isolated groups of eight channels each, with independent commons for flexible field wiring. It employs 1500VAC field‑to‑logic optical isolation to shield against electrical noise and transients, supports 10.2–28.8VDC output voltage, and delivers 5.4A inrush current for 10 ms to handle inductive loads like solenoids and small motors. The module has a 260 mA 5V backplane power draw, 0.3V max on‑state voltage drop, and 1.1 mA max off‑state leakage current, ensuring efficient and reliable operation in industrial environments. It integrates seamlessly with Series 90‑30 baseplates, power supplies, and CPUs, serving as a high‑density, isolated interface for controlling multiple DC loads in automation systems.

GE IC693MDL742

Product Overview

The IC693MDL742 is a single‑slot 16‑channel discrete output module from GE Fanuc (now part of Emerson Automation) for the Series 90‑30 PLC platform, featuring two 8‑channel groups with individual commons and Electronic Short Circuit Protection (ESCP). It uses positive logic (sourcing) to drive 12/24VDC loads, with 1500V field‑to‑logic and 500V group‑to‑group isolation, plus 1A per‑channel and 3–4A per‑group current ratings (temperature‑dependent). The module delivers 5.2A inrush for 10 ms, 1.2V max voltage drop, 1 mA max off‑state leakage, and 2 ms max on/off response times, with 130 mA max 5V backplane draw. It integrates with all Series 90‑30 CPUs, baseplates, and power supplies, serving as a protected, high‑density output interface for industrial solenoids, indicators, and motor starters.

GE IC693MDL730

Product Overview

The IC693MDL730 is an 8‑channel discrete output module from GE Fanuc (now part of Emerson Automation) for the Series 90‑30 PLC platform, providing 12/24VDC positive logic transistor outputs in a single group with a shared common terminal. It uses 1500V field‑to‑logic isolation to protect against noise and transients, supports 2A per‑channel current capacity, and offers 9.4A inrush current for 10 ms to handle inductive loads. The module has a 2A group fuse at 60°C (4A at 50°C) for overload protection, a 5V backplane power draw of 120 mA, and operates with an external 12/24VDC supply (10.2–28.8VDC range). It serves as a high‑current interface for controlling industrial actuators, solenoids, and motor starters in harsh environments.

GE IC693MDL655

Product Overview

The IC693MDL655 is a single‑slot 32‑channel discrete input module from GE Fanuc (now part of Schneider Electric) for the Series 90‑30 PLC platform, designed to interface 24VDC field devices with positive/negative logic compatibility. It features four isolated groups of 8 channels each, with independent commons for flexible wiring, and 1500V field‑to‑logic isolation via optocouplers plus 250V group‑to‑group isolation for noise immunity. The module operates from 11.5–30VDC (ON) and 0–5VDC (OFF), with 7mA typical ON current at 24VDC, 2ms max on/off response times, and 195mA max 5V backplane draw. It integrates with all Series 90‑30 CPUs, baseplates, and power supplies, serving as a high‑density, reliable input interface for industrial sensors, switches, and digital devices.

GE IC693MDL340

Product Overview

The IC693MDL340 is a 16‑channel discrete output module from GE Fanuc (now part of Schneider Electric) for the Series 90‑30 PLC platform, delivering 120VAC relay outputs divided into two isolated groups of 8 channels each. Each group has an independent common terminal, supporting separate AC phases or shared power for flexible field wiring. It features 1500V isolation between field and logic sides, 500V group‑to‑group isolation, 0.5A per‑point/3A per‑group current capacity, and 20A inrush per cycle for inductive/incandescent loads. Built‑in 3A group fuses and RC snubbers protect against transients, while a 5V backplane draw of 315 mA ensures compatibility with Series 90‑30 power supplies. It serves as a robust interface for controlling industrial actuators, valves, and motor starters in harsh environments.

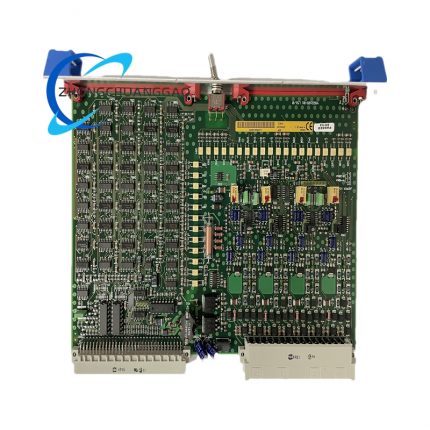

GE IC693CPU363 Single‑Slot High‑Performance CPU Module for Series 90‑30 PLC Systems

Product Overview

The IC693CPU363 is a single‑slot modular CPU module from GE Fanuc (now part of Schneider Electric) for the Series 90‑30 PLC platform, powered by a 25 MHz 80386EX 32‑bit processor. It has 240 KB user program memory, a 0.22 ms/1K Boolean scan rate, and supports up to 8 baseplates (1 CPU + 7 expansion/remote). The module provides 2048 discrete I/O points each, 2048 analog input words, 512 analog output words, and 32‑bit floating‑point math. It features three serial ports (2 onboard + 1 via power supply) with SNP/SNP‑X master/slave and RTU slave protocols, enabling seamless programming, diagnostics, and HMI/SCADA integration. Compatible with PCM/CCM specialty modules, it serves as a scalable core for medium‑to‑large automation systems requiring high processing performance and flexible expansion. RAM is backed by a battery for program/data retention during power loss.

GE IC693CPU351‑HT

Product Overview

The IC693CPU351‑HT is a single‑slot, high‑performance modular CPU module from GE Fanuc (now part of Schneider Electric) designed for the Series 90‑30 PLC platform. It is equipped with a 25 MHz 80386EX 32‑bit processor, offering a fast scan rate of 0.22 ms per 1K Boolean logic, and features 240 KB user program memory (with firmware 9.0+), three serial ports, and compatibility with PCM/CCM specialty modules. The module supports up to 2048 discrete I/O points each for inputs and outputs, 2048 analog input words, 512 analog output words, and 32‑bit floating‑point math, serving as a scalable core for medium‑to‑large industrial control systems requiring high processing power, flexible communication, and distributed I/O expansion. It uses Flash/RAM for data storage, has a battery‑backed real‑time clock, and supports SNP/SNP‑X master/slave and RTU slave protocols for seamless integration with HMIs, SCADA, and programming tools.

GE IC693CPU350‑BC Single‑Slot Modular CPU Module for Series 90‑30 PLC Systems

Product Overview

The IC693CPU350‑BC is a single‑slot modular CPU module from GE Fanuc (now part of Schneider Electric) for the Series 90‑30 PLC platform, powered by a 25 MHz 80386EX 32‑bit processor. It supports up to 8 baseplates (1 CPU baseplate + 7 expansion/remote baseplates), offering 32 KB user program memory, 0.22 ms/1K Boolean scan rate, and 32‑bit floating‑point math for complex industrial control. The module provides extensive I/O capacity (2048 discrete I/O points each, 2048 analog input words, 512 analog output words) and compatibility with PCM/CCM specialty modules, making it a scalable core for medium‑to‑large automation systems requiring high processing performance and flexible expansion. It leverages the baseplate power supply’s RS‑485 port for SNP/SNP‑X slave communication, ensuring seamless integration with programming tools and HMIs.