GE RXE2N0F7G132A

Product Introduction

The GE RXE2N0F7G132A is a high‑performance, rugged 2‑slot industrial PC (IPC) belonging to the PACSystems RXi‑XP series, designed for demanding industrial environments requiring reliable computing at the machine level. It integrates an Intel Core i7 processor running at 2.5 GHz, 8 GB DDR3 ECC RAM, and a 320 GB SATA hard disk drive, pre‑installed with Windows 7 Ultimate to support HMI, data historian, and real‑time analytics applications. The fanless design, coupled with industrial‑grade components and passive cooling, ensures stable operation in harsh conditions with temperature extremes, shock, and vibration. It features 5 Gigabit Ethernet ports for seamless connectivity to PLCs, DCS, and plant‑wide networks, along with 2 PCI expansion slots for custom I/O cards, making it a versatile platform for industrial automation, process control, and data acquisition systems.

GE RS-FS-9001 362A1052P404

Product Introduction

The GE RS-FS-9001 362A1052P404 is a high-performance ultraviolet (UV) flame detector engineered for industrial combustion safety systems, specifically designed for gas turbine flame tracking and critical combustion process monitoring. It employs a silicon carbide (SiC) photodiode sensor to detect UV radiation emitted by flames, delivering rapid response to flame presence or absence and minimizing false alarms through advanced spectral filtering and dynamic threshold algorithms. The detector operates on a 2-wire loop-powered configuration, providing a 4-20mA analog output that integrates seamlessly with control systems, PLCs, and safety shutdown devices. It features a stainless steel body with a 3/4" NPT female connector, ensuring durability and protection against harsh industrial environments, including high temperatures, corrosive atmospheres, and vibration.

GE RANGE-80 TO 20°C

Product Introduction

The GE HygroPro series dew point transmitter with measurement range -80°C to 20°C is a high-precision moisture monitoring device engineered for industrial applications requiring accurate and reliable dew/frost point measurement in gases. It utilizes advanced sensor technology to deliver stable readings across the -80°C to 20°C range, with rapid response to moisture changes and robust performance in harsh environments. The transmitter features a Type 4X/IP67-rated enclosure for protection against dust and water ingress, ensuring durability in outdoor, offshore, and industrial settings.

GE PQMII-T20-C-A

Product Introduction

The GE PQMII-T20-C-A is a high-precision three-phase power quality meter from GE Multilin’s PQMII series, tailored for industrial and utility applications requiring advanced power monitoring, harmonic analysis, and energy management. It delivers comprehensive measurement of electrical parameters, in-depth harmonic analysis up to the 63rd harmonic, and high-speed capture of voltage sags, swells, flicker, and transient events. It is equipped with 1 isolated 4-20mA analog input, 4 isolated 4-20mA analog outputs, 4 digital inputs, and 4 programmable relay outputs, alongside multiple communication interfaces for seamless integration with SCADA, PLC, and energy management systems.

GE PQMII-T20

Product Introduction

The GE PQMII - T20 is a high - precision three - phase power quality meter from GE Multilin’s PQMII series, designed for continuous monitoring, analysis and energy management of electrical power systems. It precisely measures a full set of electrical parameters, performs in - depth harmonic analysis up to the 63rd harmonic, and captures transient events like voltage sags, swells, and flicker with high - speed sampling. It is equipped with 4 isolated 4 - 20mA analog outputs, 4 programmable relay outputs, 4 digital inputs, and multiple communication interfaces, enabling seamless integration with SCADA, PLC, and energy management systems.

GE PCH1026CHF861016

Product Introduction

The PCH1026CHF861016 is a high-precision triaxial digital structural vibration monitor engineered by GE Vernova for low-frequency vibration monitoring in wind energy and industrial applications. It integrates three internal accelerometers (X, Y, Z axes) to capture comprehensive structural motion data, supporting up to 4 independent frequency bands per sensor for detailed analysis. The module employs advanced DSP technology and field-proven filtering algorithms to measure RMS, peak, and peak-to-peak values with exceptional accuracy.

GE P110-6052

Product Introduction

The P110-6052 is a high-reliability 24 VDC redundant power supply module designed by GE Vernova for industrial automation and turbine control systems. It delivers a stable 24 VDC output to support critical loads in PACSystems RX3i/RX7i programmable automation controllers and Mark VIe turbine control systems. The module features redundant architecture, enabling seamless switchover between two power inputs to eliminate single points of failure and maximize system availability. It integrates advanced protection mechanisms against overvoltage, overcurrent, short circuits, and over-temperature, ensuring the safety of connected devices and the power supply itself.

GE NE724A

Product Introduction

The NE724A is a high-density, 48 VDC digital input module from GE Vernova, engineered for reliable monitoring of discrete signals in industrial automation and turbine control systems. It features 16 isolated input channels, each with optical isolation to eliminate ground loops and noise interference, ensuring accurate signal acquisition in harsh industrial environments. The module integrates seamlessly with GE’s Mark VIe turbine control systems and PACSystems RX3i/RX7i programmable automation controllers, supporting ToolboxST configuration software for quick setup and diagnostics.

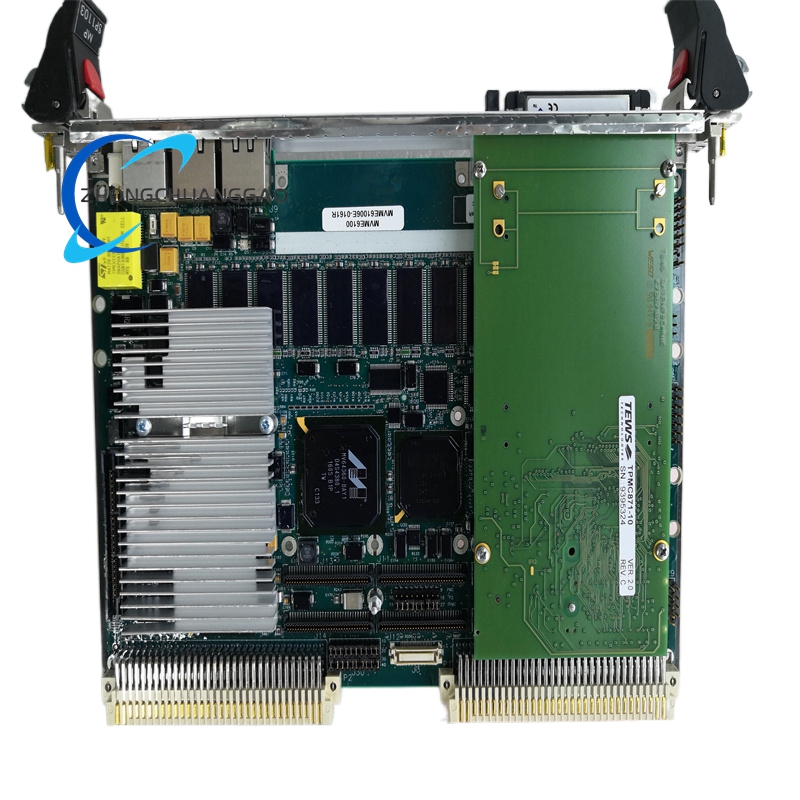

Motorola MVME-6100

Product Introduction

The MVME - 6100 is a high - performance VMEbus single - board computer originally developed by Motorola, now under GE (via Emerson Network Power acquisition). It is the first VMEbus SBC to feature the Tundra Tsi148 interface chip supporting the 2eSST (two edge source synchronous transfer) protocol, which boosts VMEbus practical bandwidth to 320MB/s. Powered by a 1.267 GHz MPC7457 PowerPC processor with a 128 - bit AltiVec parallel processing coprocessor, it delivers robust computing power for real - time data processing and control. It comes with up to 2GB DDR ECC SDRAM, 128MB on - board flash memory, dual Gigabit Ethernet ports, and dual PMC/XMC expansion slots, making it suitable for mission - critical scenarios that demand high reliability, determinism, and scalability.

GE MVAX31S1DE0754A

Product Introduction

The MVAX31S1DE0754A is a dedicated trip circuit supervision relay from GE Grid Solutions (formerly AREVA) designed to continuously monitor the integrity of medium-voltage circuit breaker trip circuits in power systems. It verifies the functionality of trip coils, wiring, and auxiliary contacts under both open and closed breaker states, detecting faults such as open circuits, short circuits, and ground faults in real time. The relay generates alarm and trip block signals upon fault detection to prevent failed breaker operations and enhance system reliability. It integrates with substation automation systems via standard communication protocols, supports seamless integration with existing protection schemes, and operates in harsh industrial environments with robust design and global certifications.GE MLJ1005B010H00C

Product Introduction

The MLJ1005B010H00C is a high-precision digital synchronism check relay from GE Multilin, designed to ensure safe and reliable synchronization of AC power systems during generator-to-grid or grid-to-grid interconnections. It accurately monitors voltage magnitude, frequency, phase angle, and frequency slip between two AC systems, initiating a closure signal only when all synchronization parameters fall within predefined thresholds. The relay integrates advanced digital signal processing for real-time measurement and control, with flexible configuration options for under/overvoltage supervision, phase angle matching, and frequency slip limits.

GE MIFIIPI55E10HI00

Product Introduction

The MIFIIPI55E10HI00 is a high-performance feeder management relay from GE Multilin’s MiF II series, engineered for protection, control, monitoring, and diagnostics of medium-voltage feeders in power distribution systems. It combines comprehensive protection functions, precise measurement capabilities, and flexible communication protocols to ensure reliable operation of distribution networks. The relay supports IEC 61850, Modbus RTU, and Profibus DP for seamless integration with SCADA and substation automation systems, and includes advanced features such as auto reclose, fault location, load shedding, and event recording for enhanced network management.

Reviews

There are no reviews yet.