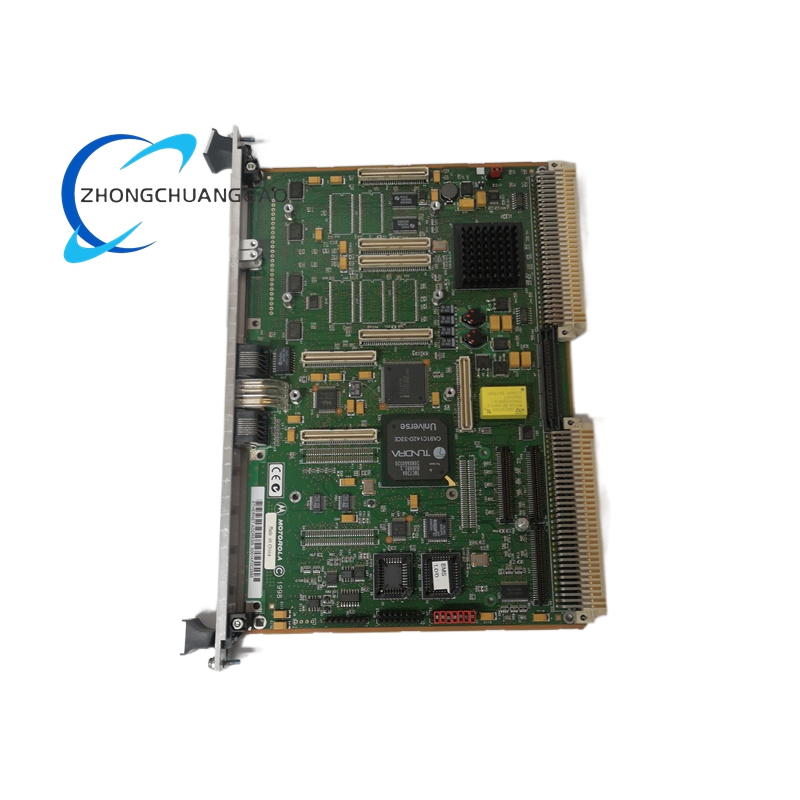

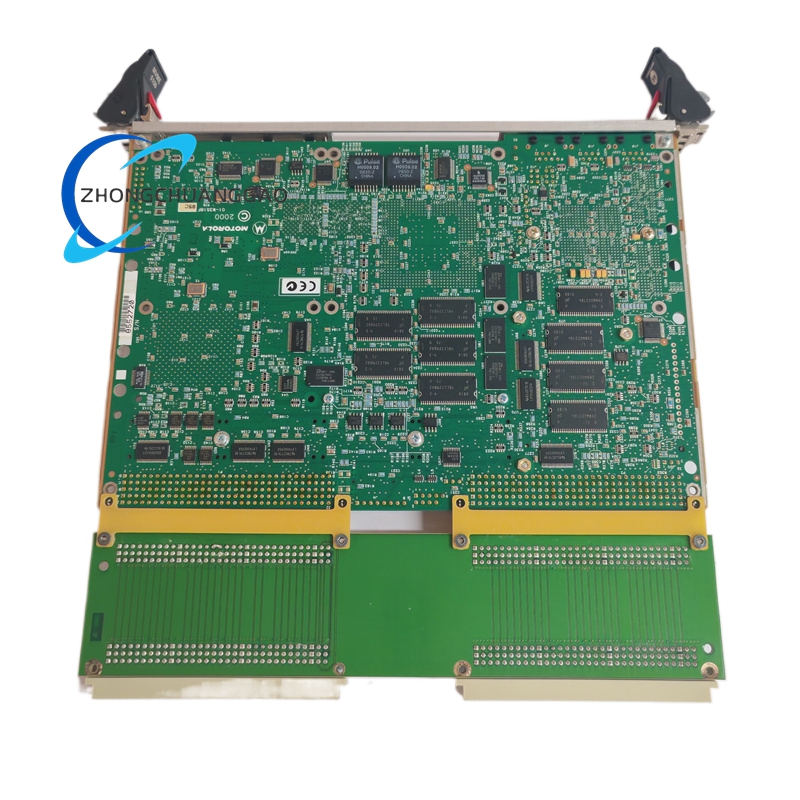

Motorola MVME2434 VMEbus Processor Module

Technical Specifications:

- Processor:

- PowerPC 750 32-bit RISC microprocessor with floating-point unit (FPU) and memory management unit (MMU).

- Clock speed: Typically 200–400 MHz (specific models may vary).

- Cache: 32 KB L1 instruction cache and 32 KB L1 data cache.

- Back-End Cache: 1 MB secondary cache for enhanced performance.

- Memory:

- SDRAM: 32 MB to 512 MB board-mounted ECC SDRAM (Error-Correcting Code) for data integrity.

- Flash Memory: 1 MB or 4 MB (depending on configuration) for firmware storage.

- NVRAM: 8 KB non-volatile RAM with battery backup for critical data retention.

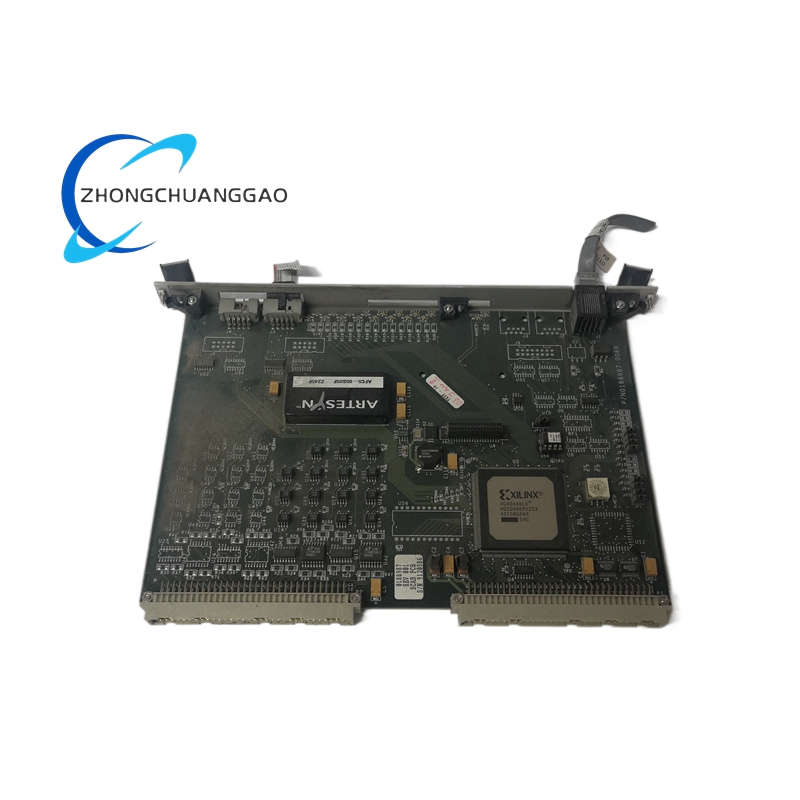

Motorola MVME2100 VMEbus Single Board Computer (SBC)

Technical Specifications:

- Processor:

- Typically equipped with an MPC8240 or PowerPC 603e processor (32-bit PowerPC architecture).

- Clock speeds range from 200 MHz to 400 MHz, supporting high-performance computing tasks like real-time data processing and complex algorithm execution.

- Integrated 16 KB L1 instruction cache and 16 KB L1 data cache to enhance instruction execution efficiency.

- Memory:

- Onboard 32 MB or 64 MB SDRAM (synchronous dynamic random-access memory) with optional ECC (Error-Correcting Code) protection for data reliability.

- 1 MB flash memory (via two 32-pin PLCC/CLCC sockets) for firmware storage.

- Supports 4 MB or 8 MB surface-mount flash memory (64-bit interface) for large-capacity storage needs.

- 8 KB NVRAM (non-volatile random-access memory), with 4 KB available for user-defined critical configuration data.

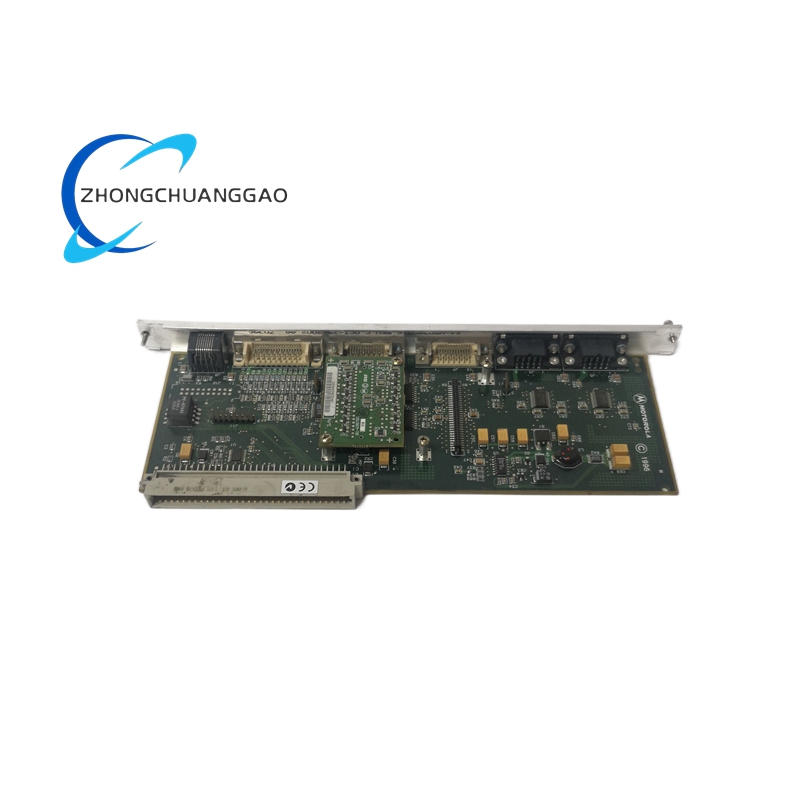

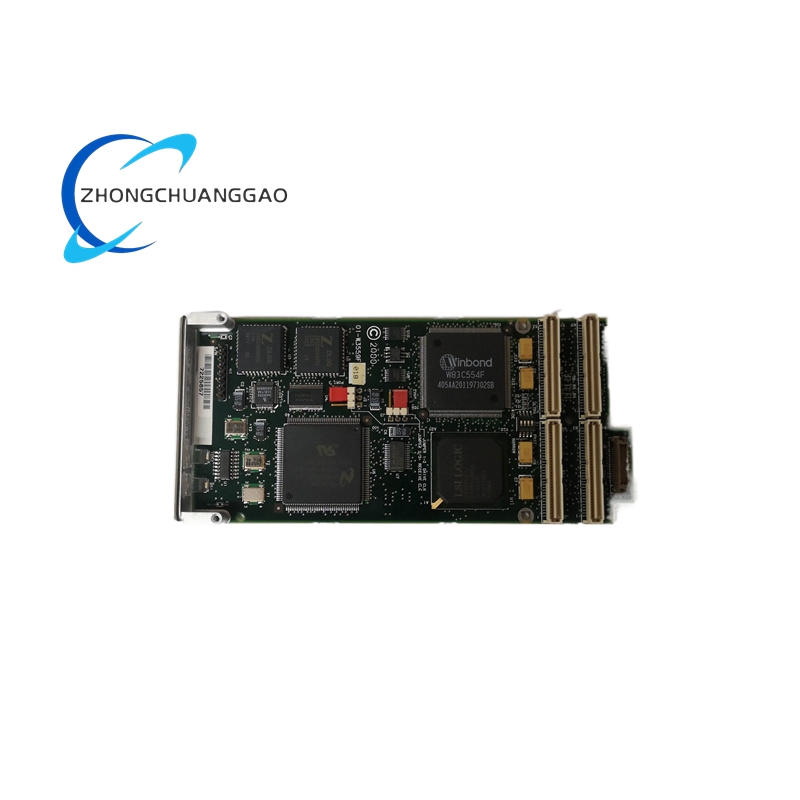

Motorola MVME761-001 VMEbus Single Board Computer (SBC)

Technical Specifications:

- Processor: PowerPC processor (specific model varies by version, e.g., MPC603e or MPC604e) with clock speeds up to 200 MHz.

- Memory:

- Up to 256 MB of SDRAM (expandable via PMC slots).

- 512 KB of battery-backed SRAM for non-volatile storage.

- Flash memory for firmware and bootloader.

- VMEbus Interface:

- A32/D32 master/slave system controller.

- Supports VME64x extensions for enhanced data transfer rates.

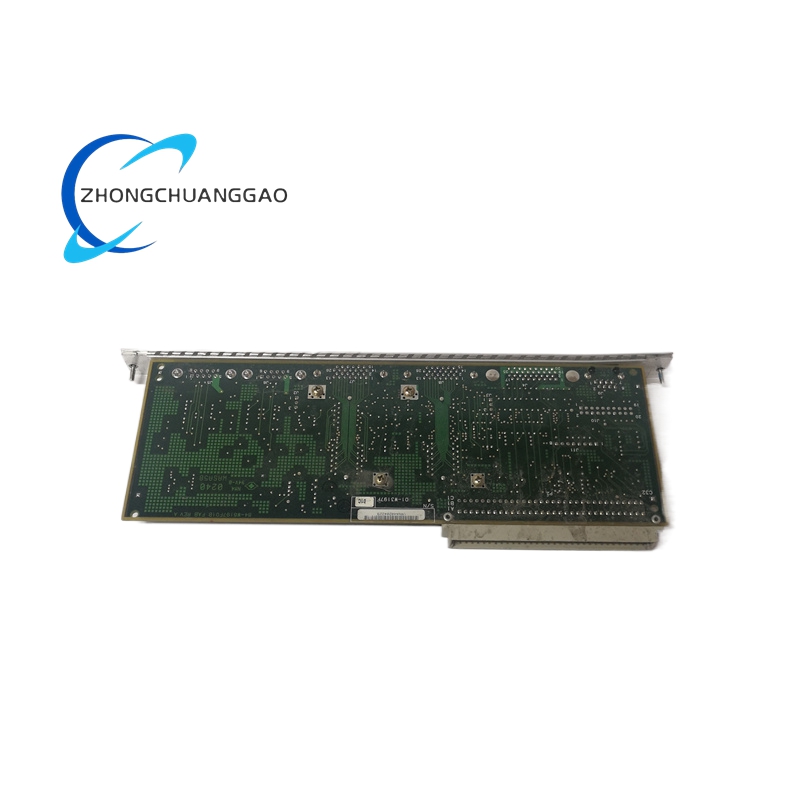

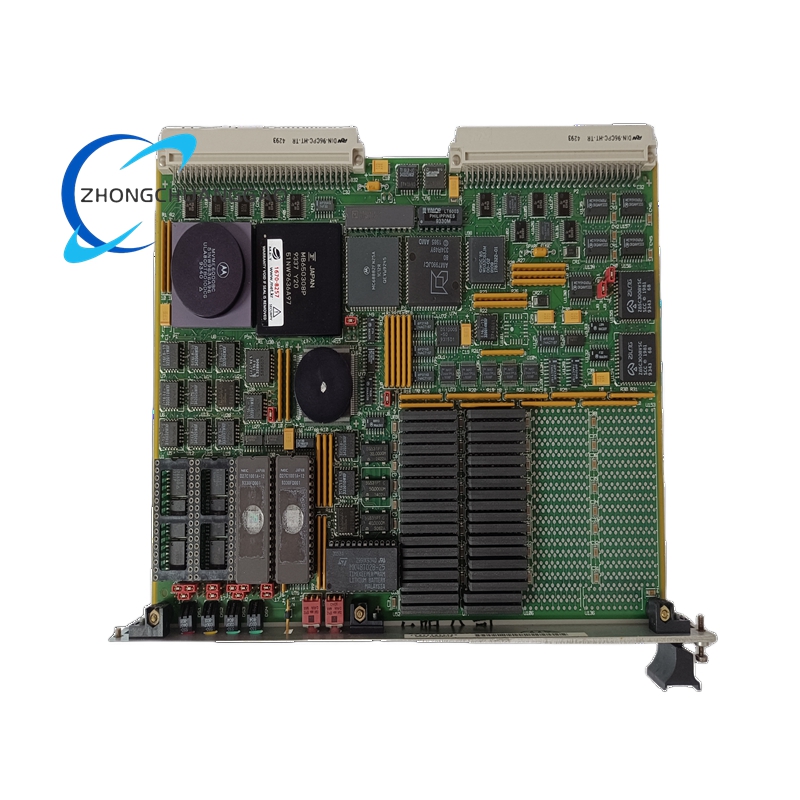

Motorola MVME162-213 Embedded Controller

Technical Specifications:

- Processor:

- 25 MHz or 32 MHz MC68040 enhanced 32-bit microprocessor with 8KB cache, MMU (Memory Management Unit), and optional FPU (Floating-Point Unit).

- Alternatively, a 25 MHz MC68LC040 enhanced 32-bit microprocessor (without FPU) is available.

- Memory:

- 4MB, 8MB, or 16MB shared DRAM with parity protection (expandable up to 64MB via expansion mezzanine).

- 512KB SRAM with battery backup for non-volatile storage.

- 1MB flash memory for firmware or user-installed applications.

- 8K x 8 NVRAM with battery backup for clock and critical data retention.

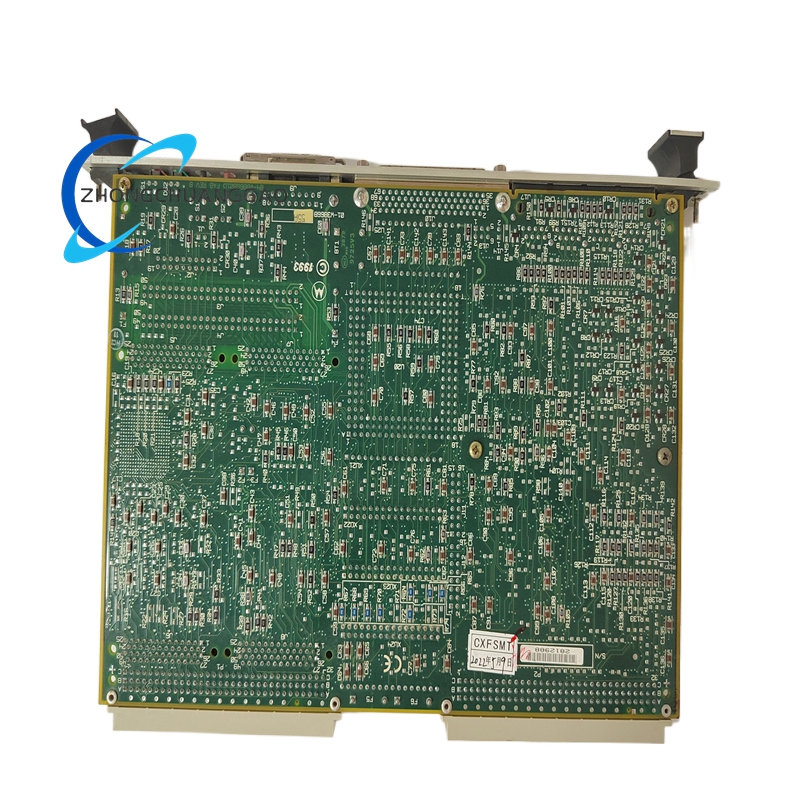

Motorola MVME147S-1

Technical Specifications:

- Processor: MC68030 enhanced 32-bit microprocessor (16/25/33.33 MHz) with on-chip cache memory, improving efficiency by 20-40%.

- Floating-Point Coprocessor: MC68882 for accelerated mathematical operations.

- Memory:

- 4/8/16/32 MB shared DRAM (with parity on MVME147S; parity-free on MVME147SRF).

- 4K x 8 SRAM with battery backup for non-volatile storage.

- Four 16-bit-wide sockets for ROM/PROM/EPROM/EEPROM.

- VMEbus Interface: A32/D32 master/slave system controller with 4-level requester and 7-level interrupt handler.

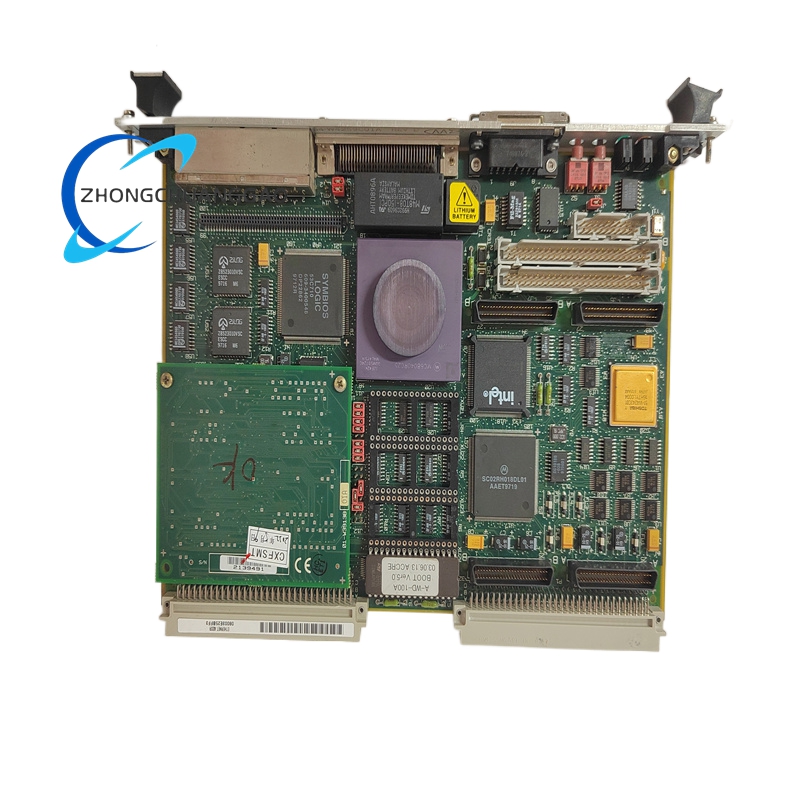

Motorola IPMC712

Technical Specifications:

- Processor: PowerPC 604e or Freescale MPC5200B, running at 400 MHz or 800 MHz.

- Memory: 256 MB SDRAM and 512 MB onboard flash memory for firmware and data logging.

- I/O Interfaces:

- One single-ended ultra-wide SCSI port.

- One parallel port.

- Four serial ports (2 or 3 asynchronous ports and 1 or 2 synchronous/asynchronous ports, depending on the module).

- PCI Interface: 32-bit PCI interface with 64-bit addressing, 8KB internal SCRIPTS RAM, and improved PCI cache design for enhanced PCI bus efficiency.

- SCSI Controller: LSI Logic SYM53C895A device with a 40 MHz clock frequency.

- Connectors: Four EIA-E700 AAAB connectors providing 32-bit PCI interface and I/O channels to the host board.

- LED Indicators: Two LED indicators for PMC status and SCSI activity.

Motorola APM-420A Power Module

Technical Specifications:

- Input Voltage: Typically supports a wide range of AC input voltages (specific range not detailed in sources, but industrial modules often support 90-264VAC).

- Output Voltage and Current: Provides stable DC output with precise voltage regulation and current limiting to protect connected devices. Exact output specifications depend on the configuration but are designed to meet the requirements of industrial equipment.

- Efficiency: High conversion efficiency, reducing energy loss and heat generation.

- Protection Functions: Includes over-voltage protection, over-current protection, and over-temperature protection to safeguard the module and connected devices.

- Thermal Management: Equipped with a thermal management system to maintain stable operation in high-temperature environments.

- Remote Monitoring and Management: Some models support remote monitoring and management via network interfaces, allowing users to monitor the status of the power system and make adjustments as needed.

- Modular Design: The module is designed for easy installation, maintenance, and replacement, reducing downtime and operational costs.

Motorola 188987-008R 188987-008R001

Technical Specifications:

- Brand: Motorola (MOTOROLA)

- Model: 188987-008R / 188987-008R001

- Origin: USA

- Power Supply: 240V DC

- Current: 24mA

- Interface: 4-channel communication ports

- Environmental Resistance: Corrosion-resistant design for harsh industrial settings

- Structural Durability: Withstands up to 5000KN of pressure

- Operational Temperature: Rated for high-temperature environments (specific range not detailed in sources).

Motorola 0188679 0190530

Technical Specifications:

- Processor: Intel Atom CPU with high computing power for real-time data processing.

- Size: One-third the size of the previous Beckhoff C6905 model, enabling flexible installation in confined spaces.

- Cost Efficiency: Approximately 25% lower price compared to prior x86 IPCs from Beckhoff, offering significant savings.

- Memory and Storage: Supports scalable memory and storage options to meet diverse application demands.

- I/O Interfaces: Includes multiple serial ports, Ethernet connectivity, and customizable PMC slots for expanded functionality.

Motorola MVME5100

Technical Specifications:

- Processor: Supports PowerPC-based microprocessors (e.g., MPC7410, MPC750, MPC755) with clock speeds up to 1.5 GHz, offering high performance and low power consumption.

- Memory:

- 128 MB SDRAM (expandable to 1 GB via mezzanine cards).

- 2 GB IDE or solid-state drive (SSD) for storage.

- I/O Interfaces:

- 2x RS-232C serial ports.

- Dual 10/100BaseTX Ethernet ports for high-speed networking.

- PCI and CompactFlash slots for peripheral expansion.

Kollmorgen S72402-NANANA S700 Series 3-Phase High-Power Digital Servo Drive

Key Features

- Multi-Motor Compatibility: Drives synchronous, servo, linear, DC, and asynchronous motors, eliminating the need for multiple drive types in mixed-motor systems.

- High Dynamic Performance: 5 kHz current loop bandwidth and 24 ARMS continuous current enable fast torque response and precise motion control for high-inertia loads.

- Comprehensive Safety: STO (SIL 3 / PL e) prevents unexpected motor startup during maintenance, ensuring operator and equipment safety.

- Flexible Communication: On-board EtherCAT/CANopen plus optional fieldbus expansion support seamless integration into diverse automation architectures.

- Robust & Compact Design: IP20 chassis resists dust and vibration; passive cooling avoids fan-related failures, extending service life in harsh settings.

- Simplified Commissioning: Kollmorgen WorkBench enables auto-tuning, real-time monitoring, parameter backup/restore, and fault diagnosis, reducing setup time by up to 50%.

- Wide Voltage Range: 208–480 VAC input compatibility allows global deployment without hardware modifications.

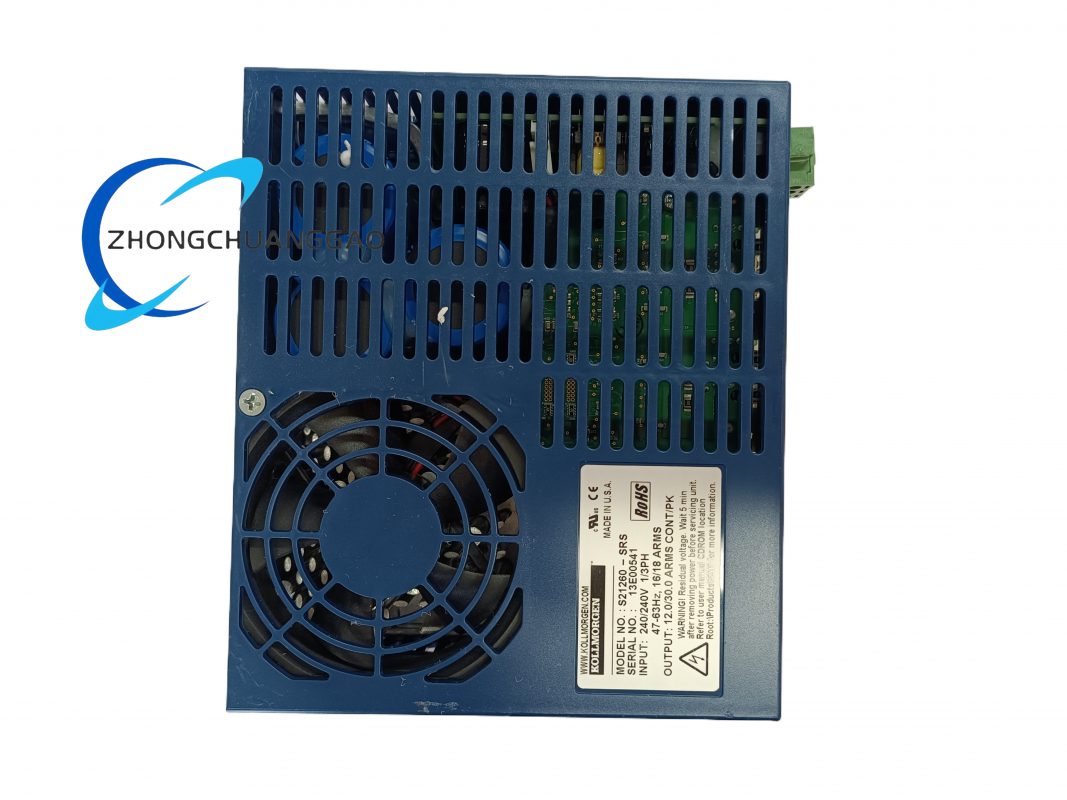

Kollmorgen S21260-SRS S200 Series High-Performance Compact Brushless Servo Drive

Key Features

- SynqNet Real - Time Communication: The on - board SynqNet interface realizes deterministic multi - axis synchronization, low - latency data transmission, and easy system expansion, which is suitable for high - speed and high - precision coordinated motion applications.

- High - Resolution Feedback & Control: 24 - bit feedback resolution and 5 kHz current loop bandwidth ensure micron - level positioning accuracy and low - ripple speed regulation, and minimize following errors in complex motion trajectories.

- Keep - Alive Power Function: The dedicated 24 VDC control power maintains communication and system parameters during emergency stops or power dips, enabling fast recovery and reducing downtime.

- Comprehensive Protection Mechanisms: Integrates overvoltage, undervoltage, overcurrent, short - circuit, overheating, phase - loss, and motor stall protection to fully protect the drive, motor, and connected equipment.

- Compact Fan - Less Design: The slim form factor saves cabinet space, and the fan - less design eliminates mechanical failure points, improving long - term operational reliability in dusty industrial environments.

- Simplified Commissioning: Supports automatic motor parameter identification and one - click auto - tuning; Kollmorgen WorkBench software provides real - time monitoring, parameter backup/restore, and fault diagnosis functions, shortening the commissioning cycle.

Reviews

There are no reviews yet.