GE SR750-P5-G5-S5-HI-A20-R Multilin Feeder Management Relay

Product Introduction

The GE SR750-P5-G5-S5-HI-A20-R is a feeder management relay designed for comprehensive protection, control, and monitoring of electrical feeders in industrial and utility applications. It belongs to GE's Multilin SR750 series, known for its advanced functionality, high reliability, and robust design. This relay ensures the stable, efficient, and safe operation of feeder systems by monitoring key parameters and executing protective actions when necessary.

Technical Specifications

- Brand: GE (General Electric)

- Model: SR750-P5-G5-S5-HI-A20-R

GE SR750-P1-G1-S1-HI-A20-R-E Multilin Safety Monitoring Relay

Product Introduction

The GE SR750-P1-G1-S1-HI-A20-R-E is a high-performance safety monitoring relay designed for industrial automation systems. It provides comprehensive safety protection and status monitoring for equipment, ensuring reliable operation in harsh industrial environments. This relay is part of GE's Multilin SR750 series, known for its advanced functionality and robust design.

Technical Specifications

- Brand: GE (General Electric)

- Product Series: SR750 Series Industrial Safety Monitoring Relay

- Type: Multi-channel Safety Monitoring and Protection Relay

GE SR750-P1-G1-S1-HI-A20-R-E-H Multilin Feeder Management Relay

Product Introduction

The GE SR750-P1-G1-S1-HI-A20-R-E-H is a feeder management relay designed for comprehensive protection, control, and monitoring of electrical feeders. It belongs to GE's Multilin SR750 series, which is known for its advanced functionality and reliability in industrial and utility applications. This relay is capable of handling complex protection schemes and provides high-speed operation to ensure the safety and stability of electrical systems.

Technical Specifications

- Brand: GE (General Electric)

- Model: SR750-P1-G1-S1-HI-A20-R-E-H

- Control Power Supply: Typically 24 VDC or 120 V AC, depending on configuration

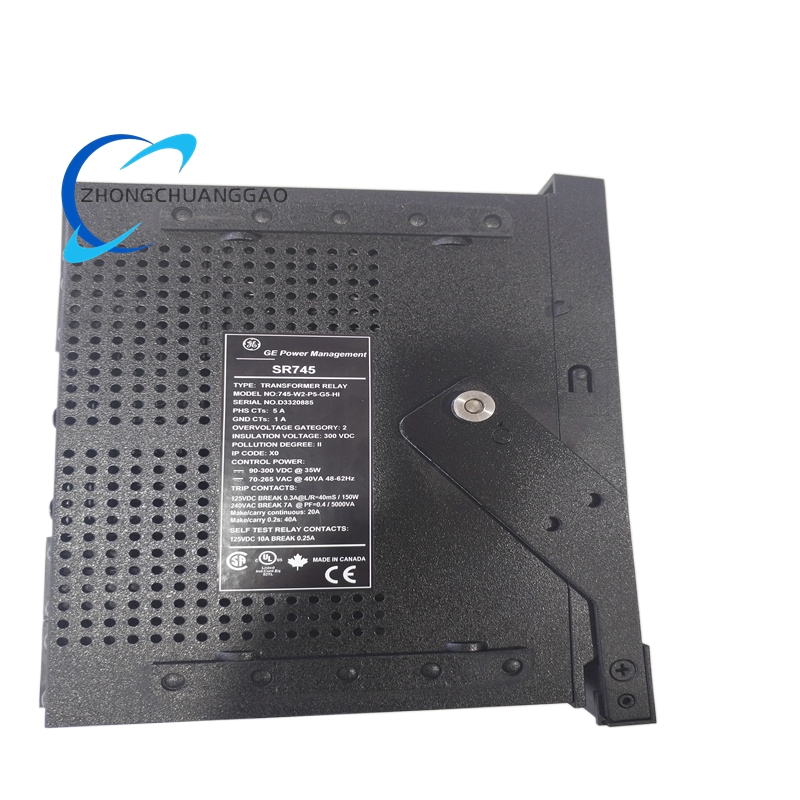

GE SR745-W2-P5-G5-HI Transformer Protection Relay

Product Introduction

The GE SR745-W2-P5-G5-HI is a transformer protection relay designed to provide comprehensive protection and management for transformers. It belongs to GE's Multilin 745 series, which is known for its high-speed operation and reliability. This relay is capable of managing both dual and triple-winding transformers, ensuring their safe operation under various conditions.

Technical Specifications

- Control Power Supply: 90 to 300 V DC or 70 to 265 V AC, 48 to 62 Hz

- Operating Temperature: -40°C to +60°C (-40°F to +140°F)

- Storage Temperature: -40°C to +80°C (-40°F to +176°F)

GE SR489-P5-HI-A20-E Generator Management Relay

Product Introduction

The GE SR489-P5-HI-A20-E is a generator management relay designed for the protection and control of generators. It belongs to the Multilin 489 series manufactured by GE and is engineered to monitor and manage generator operations effectively. This relay offers comprehensive protection functions and flexible configuration options, making it suitable for a wide range of generator applications.

Technical Specifications

- Brand: GE (General Electric)

- Model: SR489-P5-HI-A20-E

- Control Power Supply: 90-300 VDC or 70-265 VAC, 48-62 Hz

GE SR489-P1-LO-A20-E Generator Management Relay

Product Introduction

The GE SR489-P1-LO-A20-E is a generator management relay designed for the protection and control of generators. It belongs to the Multilin 489 series and is manufactured by GE Multilin. This relay provides comprehensive protection functions, flexible configuration options, and high reliability, making it suitable for various generator applications.

Technical Specifications

- Brand: GE (General Electric)

- Model: SR489-P1-LO-A20-E

- Series: Multilin 489

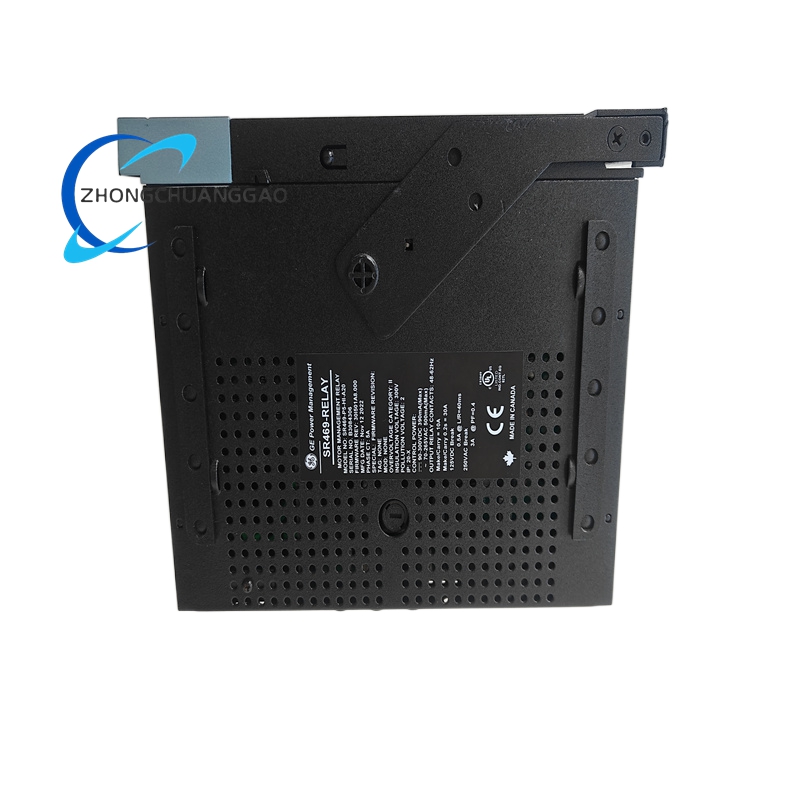

GE SR469-P5-HI-A20-E Motor Management Relay

Product Introduction

The GE SR469-P5-HI-A20-E is a high-performance motor management relay designed for the protection and control of medium to large-sized motors. It integrates comprehensive monitoring and protection functions to ensure the safe and reliable operation of motors in industrial applications.

Technical Specifications

- Brand: GE (General Electric)

- Model: SR469-P5-HI-A20-E

- Control Power Supply: 70-265 VAC, 90-300 VDC

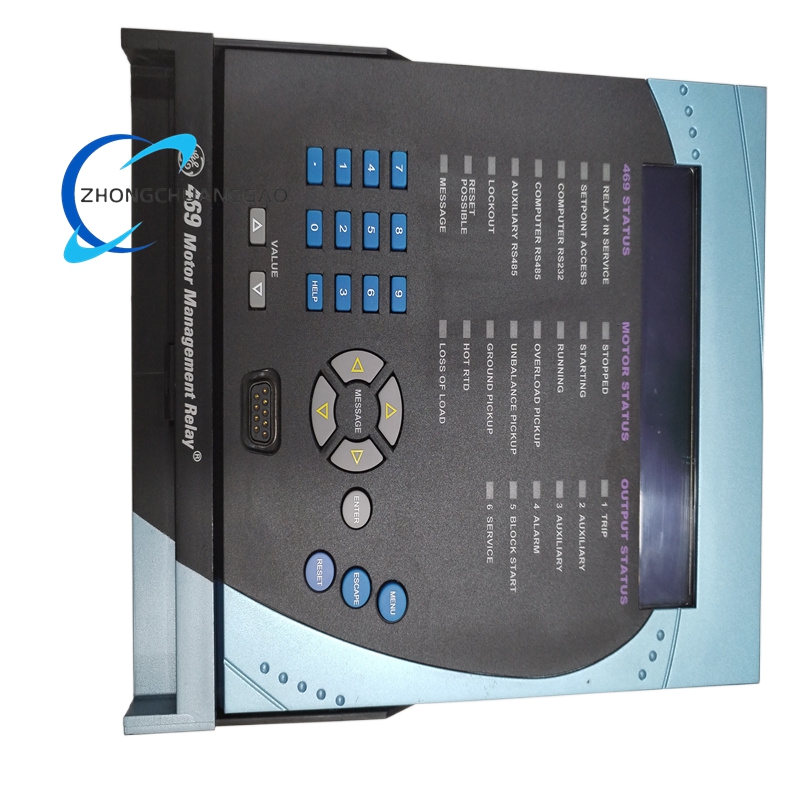

GE SR469-P5-HI-A20 Motor Management Relay

Product Introduction

The GE SR469-P5-HI-A20 is a high-performance motor management relay designed for industrial control applications. It provides comprehensive protection and monitoring functions for electric motors, ensuring safe and reliable operation. This relay is part of the GE Multilin SR469 series, specifically tailored for demanding industrial environments where motor protection is critical.

Technical Specifications

- Brand: GE (General Electric)

- Series: Multilin SR469 Motor Management Relay

- Model: SR469-P5-HI-A20

- Control Power Supply: 90-300 VDC or 70-265 VAC, 48-62 Hz

GE SR469-P1-HI-A20-T Motor Management Relay

Product Introduction

The GE SR469-P1-HI-A20-T is a high-performance motor management relay designed to provide comprehensive protection and control for electric motors. It is part of the GE Multilin SR469 series, specifically tailored for demanding industrial applications where motor reliability and safety are critical. This relay integrates advanced protection functions with monitoring capabilities to ensure the safe and efficient operation of motors.

Technical Specifications

- Brand: GE (General Electric)

- Model: SR469-P1-HI-A20-T

- Control Power Supply: Rated for 90-300 VDC or 70-265 VAC, 48-62 Hz

GE SR469-P1-HI-A20-E Motor Management Relay

Product Introduction

The GE SR469-P1-HI-A20-E is a high-performance motor management relay designed to protect and control electric motors. It is part of the GE Multilin SR469 series, specifically tailored for demanding industrial applications where motor protection is critical. This relay provides comprehensive monitoring and protection functions to ensure the safe and reliable operation of motors.

Technical Specifications

- Brand: GE (General Electric)

- Model: SR469-P1-HI-A20-E

- Series: GE Multilin SR469 Motor Protection Relay

Honeywell SPS5710 Processor Module Controller

Technical Specifications

- Brand: GE (General Electric)

- Model: SPS5710

- Voltage: Typically operates at 220V (specific voltage requirements may vary based on the application and configuration)

- Processing Capabilities: Equipped with a powerful processor to handle complex control tasks and data processing

- Connectivity: Supports various communication protocols and interfaces for seamless integration with other industrial devices and systems

- Certifications: Meets industry standards for safety, reliability, and performance

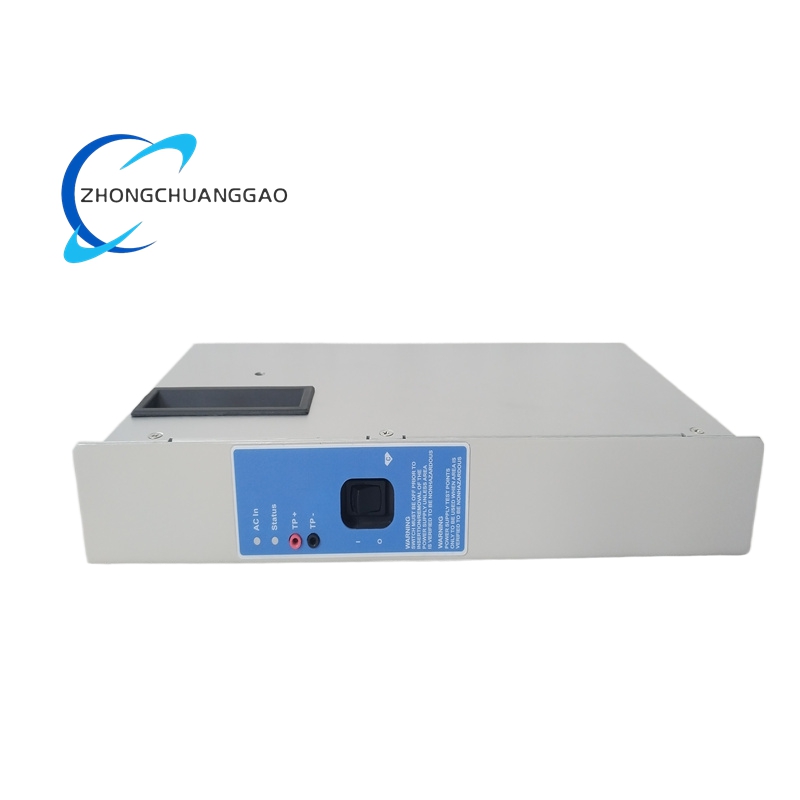

GE RXE2N0F7G132A

Product Introduction

The GE RXE2N0F7G132A is a high‑performance, rugged 2‑slot industrial PC (IPC) belonging to the PACSystems RXi‑XP series, designed for demanding industrial environments requiring reliable computing at the machine level. It integrates an Intel Core i7 processor running at 2.5 GHz, 8 GB DDR3 ECC RAM, and a 320 GB SATA hard disk drive, pre‑installed with Windows 7 Ultimate to support HMI, data historian, and real‑time analytics applications. The fanless design, coupled with industrial‑grade components and passive cooling, ensures stable operation in harsh conditions with temperature extremes, shock, and vibration. It features 5 Gigabit Ethernet ports for seamless connectivity to PLCs, DCS, and plant‑wide networks, along with 2 PCI expansion slots for custom I/O cards, making it a versatile platform for industrial automation, process control, and data acquisition systems.

-430x430.jpg)

Reviews

There are no reviews yet.